Almost all joiners prefer to connect parts with each other using dowels.

In this article, Neil, the author of the Pask Makes YouTube channel, will share with you the secret of how to make a cutter for round dowels. When the choice in the store is not great and you need dowels of a certain size, and from certain types of wood, such a tool will be very helpful.

Materials

- Solid wood massif

- Steel plate 10 mm thick

—

- Wood screws

- Sandpaper

- PVA glue.

Instruments, used by the author.

- Miter saw

- Drilling machine, set of drills

—

—

—

—

—

- Ruler, core, awl, mallet, hammer, vise, chisel.

Manufacturing process.

Your first trial fixtures for cutting dowels, the author made of a piece of steel 3 mm thick. The cutter was created without much effort from a section of a steel corner in which several holes were simply drilled with a small pitch. The dowel blanks were prepared from rectangular bars, somewhat larger than the expected dowels at the exit.

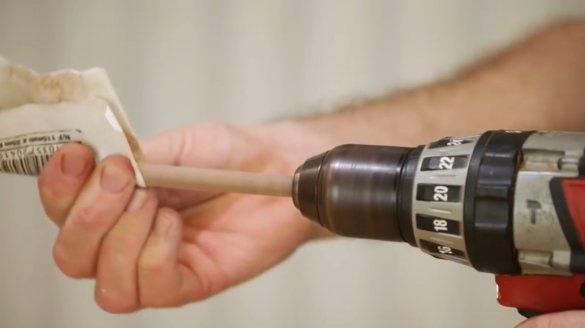

After that, the workpieces were passed through holes in a metal plate. At the end, Neil inserted each dowel into the drill chuck and additionally processed it with sandpaper until they acquired a round and regular shape.

In this article, the author will describe the improved model the same fixture. This time, the steel plate will have a thickness of 10 mm and a width of 50 mm. The author cuts it to 180 mm in length.

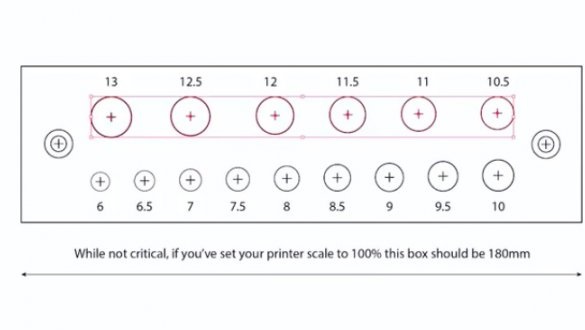

To simplify the process, Neil makes a template on the computer, where he marks out all the necessary parameters. The author has kindly provided you with a drawing of the plate with holes for this the link.

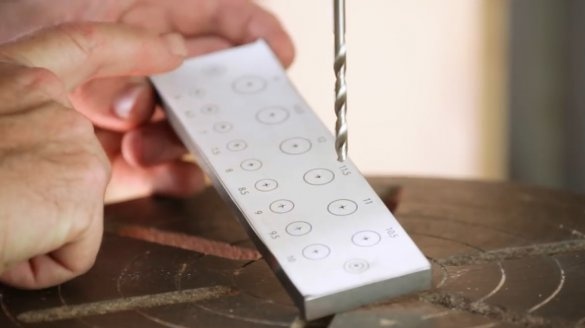

Cutting out the template, he glues it to the plate, and corns the centers of future holes.

Then he makes a series of holes of different diameters in steps of half a millimeter in order to more accurately adjust the diameter of the dowel to the required size.

The size of the holes varies from 6 to 13 mm in increments of 0.5 mm. And two more external holes at the edges are designed to fix the plate on the base with self-tapping screws. The author will drill them with a 5 mm drill, and then countersink them with a drill of a larger diameter.While work is in progress with a five-millimeter drill, the author at the same time outlines the pilot holes of the remaining 13 pieces.

A couple of holes turned out with notches. Neil cleans them on a water whetstone. The platform itself is ready.

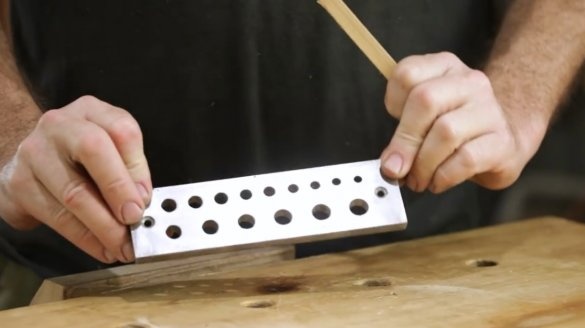

Now, to grind the dowel, you need to place a hole of the required diameter above the hole in the workbench, and punch the dowel through it with a mallet.

But the author decides to mount the board on a wooden block stand. He cuts the workpieces, and in them drills two holes for beautiful descents with a Forstner drill.

Then glues the blanks together. He wants to get a massive base.

Now cuts out the unwanted part, forming wide legs.

Neil mills a niche 10 mm deep under a steel plate, defects are processed with a chisel.

So, the niche is perfectly adapted to the size of the slab.

Now you need to mill all the sharp edges of the stand.

Then he drills the counter holes in the stand. Each hole is 2 mm wider than the holes on the plate. But it, due to its length, helps to direct the dowel vertically, and does not allow it to warp.

Now you can sign the dimensions of each hole on the plate.

It remains only to soak the wood with linseed oil, and fix the stove.

With the help of a circular saw, he cut blocks for dowels from all kinds of wood that he had in the workshop.

Now you can work with pleasure.

Another way to use this device is to clamp a wooden dowel in the drill chuck and roll it through the holes, gradually moving from a large diameter to the required one. But first you need to slightly cut off one of the ends of the dowel so that it easily goes into the hole. The other end is also slightly cut off for convenience, because a square shape is not so easy to insert into a round cartridge! The author additionally slightly passes the dowel through the holes of the steel plate and gets a rounded shape at its ends. Now things will go easier.

Here is such a collection!

The author also reports a very important observation: that dowels made of hardwood when used with a drill tend to break, while when piercing them with a hammer through holes, they turn out to be very neat and clean.

As for the dowels made of soft wood, here we get the exact opposite picture! Here is such a nuance.

The master also points out such a detail that when choosing material for the dowels themselves, it is better to select such sections of wood on which the fibers lie directly. If they lie unevenly, the probability that the dowel breaks increases many times.

Here from these varieties of wood turned dowels from the master.

From left to right: pine, edging eucalyptus, white oak, merbau, white mahogany, spotted eucalyptus, camphor cinnamon, cedar, cypress, silky oak, ball eucalyptus, colored eucalyptus, Cunningham araucaria, black-billed acacia.

Thanks to the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.