So, finally summer has come, and this is also a great time for outdoor games.

In this article, the author of the Third Coast Craftsman YouTube channel will tell you how to make a mini-golf club, this game is also called putt.

Materials

- Boards of eucalyptus edging and to

- Brass sheet

- Two-component epoxy casting resin

- Sandpaper

- leather strip

- Kapron thread

- Acetone

- Sheet plywood.

Instruments, used by the author.

- A circular saw

—

—

—

—

- Drilling machine

- Miter saw

- Needle file, rasp, awl

- Steam generator

- Air compressor, pressure chamber

- Belt and drum grinding machines

- A plane, a zenzubel, chisels, a hammer, a square, a carpentry knife, a ruler, a pencil.

Manufacturing process.

The author intends to make these golf clubs from hard, exotic woods with very dense wood. He opts for eucalyptus fringing (Eucalyptus marginata) for one club, and for (Hymenaea courbaril) for another. First of all, the master cuts and smoothes out two blanks for club heads.

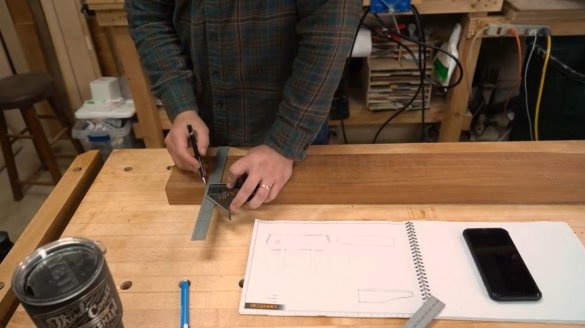

After checking the geometry of the workpieces, cuts each of them into two parts with a Japanese saw.

Then the ends are aligned with a planer.

The author marks and drills several holes in the workpieces, in places of contact with epoxy resin. When it flows there and hardens, this design will significantly strengthen the connection heads of clubs.

For this case, the author has in store the freshest casting resin Total Boat, designed specifically for casting massive parts. However, it is necessary first to grind the joints, and degrease them with acetone.

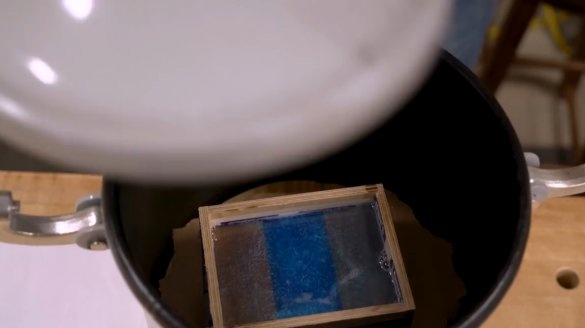

Now the master made the simplest formwork from plywood, and pasted it with a film. And in order to prevent the workpieces themselves from surfacing, he glued them to the bottom using hot-melt adhesive.

In the beginning, the master was going to make one club from a transparent, clean resin.

But he mixed too much epoxy, so he decided to make another club with an epoxy insert, while he slightly tinted the composition, giving it a bluish tint. At the end of the article, both clubs will be in the photos: which one do you think looks more advantageous?

Then he immerses the gate in the pressure chamber and pumps pressure.This procedure allows you to get rid of the bubbles in the solution up to the smallest, invisible to the naked eye.

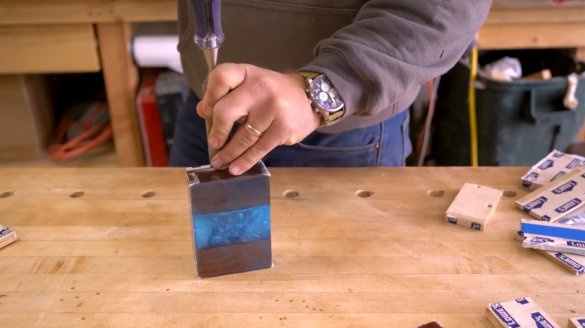

After both blanks have completely cleared of bubbles and the resin has polymerized, the author takes them out of the chamber and removes the formwork.

Then trims and strips them to their final shape.

The radius elements of the workpieces are cleaned on a drum grinder.

An ordinary golf club weighs about 350 grams, these same clubs will not be as heavy. To increase their weight, the author makes inserts from sheet brass.

Cutting and processing the inserts for the bottom, marks the places of future recesses for them with a knife.

The grooves are cut using a hand mill, and their edges are finalized with a chisel.

Then simply paste the inserts into place.

However, hockey sticks were still somewhat underweight. The author recommends to his readers to use thicker brass inserts, or to integrate LED lighting under brass inserts. You can also make larger grooves and increase weight with lead weights.

Then, in the epoxy surface, he cuts a small groove, and glues a brass wire into it for better visibility of the center line.

After that, the hockey sticks are made from sticks. The master cuts them in a cylindrical, conical shape on a band saw, and then processes them on a grinding machine and a manual plane.

The pen should take on such a shape that it can go into the club head at the right angle. To do this, the author steams the tree in a special container using a steam generator for an hour. You can find links to this device in the comments under YouTube video.

While the wood is hot and wet, it bends easily. The master bends the handle, pressing with clamps. And leaves to dry. After that, the required form will be saved.

He decides to handle one of the pens in the shape of his grip. This is achieved with a rasp and sanding.

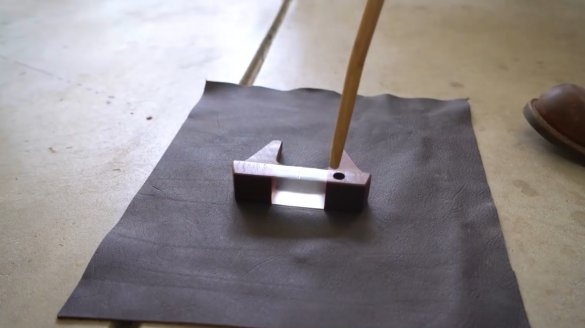

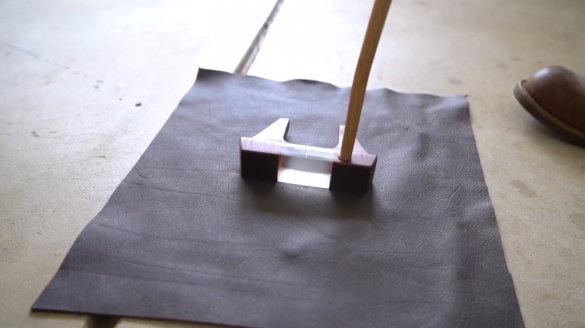

After the entire processing process, the handle is wrapped with a piece of leather in order to make it comfortable to hold in your hand.

The leather lining is hand-sewn with kapron thread.

The last knot is tied, and its tail is removed under the seam.

Excess skin is cut off.

The last step is the pen is attached to the club head with a small amount of epoxy.

And here is the long-awaited result. The master additionally impregnated all the wooden elements with linseed oil, and added a couple more brass plates.

And here he is a triumph! Right on target! You can play with such clubs even in an apartment, not to mention a small lawn or field. This game should appeal to both adults and children.

Thanks to the author for an interesting and beautiful idea of a mini-golf club!

All good mood, good luck, and interesting ideas!

Author video can be found here.