Initially, to make a compact smokehouse from what has already served, worked, was not. It’s just "itching your hands" to make something, zabatsat. But already in the process it turned out that everything I used for this homemade, used: some hardware - not counted. The same extraction rivets are, by default, disposable.

So, its basis, the body is a coffee can. But I’ll make a reservation right away: it’s not about a “wonderful product in a compact case”, when an ordinary tin can of coffee, with a volume of 200-250g, becomes a full-fledged smokehouse for meat, lard and fish. No, I got her “elder brother”, more precisely, if we take into account the capacity-sizes, then the “great-grandfather” containing 3 kg of grains.

Its dimensions are 20 cm in diameter and 35 in height. By simple calculations, the volume of this jar is almost 9 liters: quite a lot. But only when she came across to me, I had no idea what to make of it. Therefore, I left it until better times.

And then a friend, "part-time" installs air conditioners, being at my place and appreciating the stove and barbecue from freon cylinders he hinted: you will need to ask you to make a small smokehouse. That he was tired of dying purchased undercoats, chicken, and mackerel to death. And you need to cook it yourself.

No sooner said than done. That's just his proposal, to use freon cylinder for this homemade product, he rejected: he is still not so high. When he shared the idea with his wife, she doubted: his walls were too thin, would not burn out after the first or second time? But that is the secret of smoking, and not frying on an open fire / charcoal, that the temperature in the smoking chamber is much lower. And smoldering coals are located only at the very bottom. Where, in fact, the cylinder has a really thick bottom. On this, doubts about the correctness of the chosen solution ended, so I started to work.

The neck was haunting: where will I find a similar cork? "Native" because plastic.

Therefore, I didn’t come up with anything better than just cutting it off: then I’ll close it with a pair of large washers.

But with the bottom it would be worth playing better. Its shape is "steps",

and the lid found in the bins with high sides,

Allowed to make a water lock and use the smokehouse even at home, just on the stove. But firstly, I don’t know how to cut a grinder well (I didn’t even think of taking an electric jigsaw for this), and secondly, after clarification, I found out that this was useless for the customer. A friend planned to use it in the garage: and then let all the neighbors get envious - they choke on their saliva. Therefore, I cut it like that.

The height of the cylinder allows you to smoke on two levels, so I cut two circles with a diameter of 18 cm from a metal sheet with holes from some mechanism.

And so that they enter the future smokehouse through an opening of 15 cm, cut them. But not just in half, but cutting out about a centimeter between the halves.

On the piano loop, I connected them with rivets, made small stops so that it did not close in the opposite direction, and made handles from two coupling bolts. He did the same with the second cut out net.

Similarly did for stoves folding mesh.

The wife, who actually “presented” this cover, warned: the navel is not native and is very hot.

Therefore, I did not wait for the first burn, but replaced it with a wooden one, replacing the native M4 stock with a more powerful and reliable M6.

And again, the question arose: what about those products that are not laid out on shelves, but should hang? The same carcasses of fish?

From the bottom left after cutting, I made this detail:

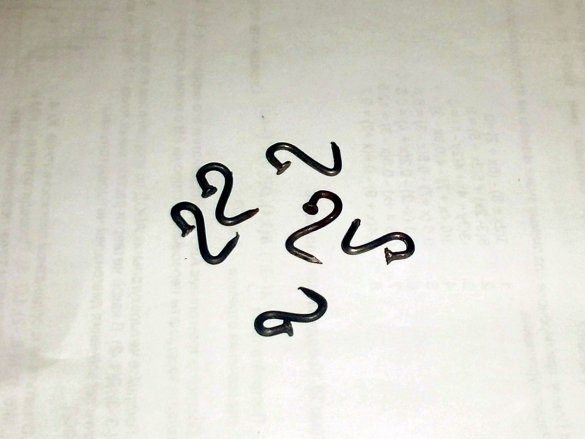

And to hang products, he made six hooks from nails:

Connected them

and on my favorite pinch bolt, secured to the back of the cover.

So the handle will be fixed, and the circle with hooks will not be pulled tightly.

Washers to close the cut neck. I didn’t find the M6-M10 with a large shelf, so I made such a “sandwich”. On the furniture bolt with an M8 nut at the edges are two ordinary washers. And those that will be adjacent to the cylinder inside and out - M22.

Tightened - the pucks squeezed the cut neck a little more, so it turned out fine.

Even checked for clearance and water - hermetically. Although this I did not achieve.

But it turned out a vanka-vstanka: the design is completely unstable. So, you need to make legs. Marked holes for four legs. On three I would have been as stable, but the first test drive was planned to be carried out in a similar barbecue. And it has a rounded bottom, so it is.

Screw from the coupling bolt, washer (missed with hole diameter), nut: all four times.

Reciprocal parts from coupling bolts. The legs are ready.

Now stops for shelves. I didn’t “invent bike”, M4 screws with a large external head 20 mm long and nuts with washers. I drill holes (neatly, the walls are thin),

and tighten them.

Distances - with a margin: the height of the can allows you to place products on them when smoking is not close. I even thought that it was possible to make three shelves, but oh well.

Shelves become excellent. First one:

the second

and on top everything closes with a lid.

But when I did, I realized: there are not enough external pens. Obeying a sporting interest - to use only recyclables, he took pens from the old kitchen: not so long ago changed it to a new one. Slightly curved (the shape of the smokehouse is rounded)

and drilled four holes,

fastened them with short M4 screws from the inside.

It turned out not the most convenient pens - I still love it more massive, plus they will heat up when smoked. However, no one will use them when cooking: and to put the smokehouse "on the cold", they’ll leave.

Capacity for draining fat when smoking. I was trying to buy something suitable at the nearest hardware store, but no. At first, rummaging in the country I found some trash. He planned to attach a handle to it - a part with a thread from the anchor bolt, as well as legs, but changed his mind. How long this capacity will last is unclear, so I’m making a spacer. And then what will become of it later is the second question.

In two pieces of a rod with an M6 thread 160 mm long, I made cuts,

and then my auto repairman cooked them. The result is such a plus sign.

Having drilled four holes in the walls, on the coupling bolts (well, I love them), I put it inside. And in order not to overtighten them, or the bolts did not loose over time, he locked them with nuts. The smokehouse is ready.

But all this is nonsense: such home-made is guaranteed to be interesting not by the process, but by the result. But only in my case, I did not try it: I did it to myself.And so as not to give a friend a "second-hand smokehouse", he gave him that.

He promised that after the first test drive he would not only share his impressions, photos, but also bring a piece of something smoked.

Let’s see if it will be so or not.