Greetings the inhabitants of our site!

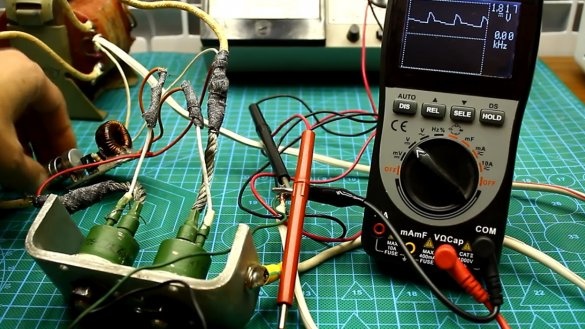

Not so long ago, the author of YouTube channel “AKA KASYAN” turned out to have such a three-phase power transformer from a deep vibrator for laying concrete.

The disadvantage of this transformer is that its windings are wound with an aluminum wire. And the plus is that the voltage of the secondary windings is about 36V.

In general, the author decided to make a home-made welding machine out of this transformer. The output voltage is sufficient for normal ignition of the arc.

Transformer welding machines were supplanted by more compact and lower weight inverter welding machines. But the indisputable advantage of transformer welding machines is extremely high reliability and long-term constant load.

The welding machine itself consists of 2 main parts: a power transformer and a welding current control system.

If the device is a direct current, then it also includes a rectifier.

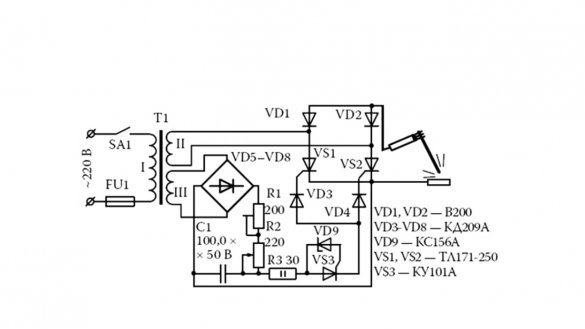

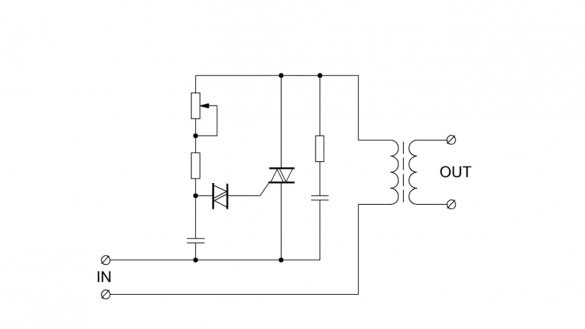

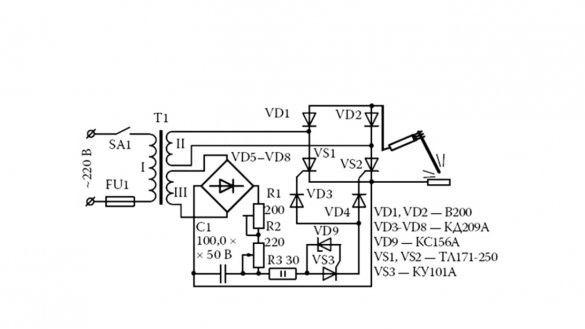

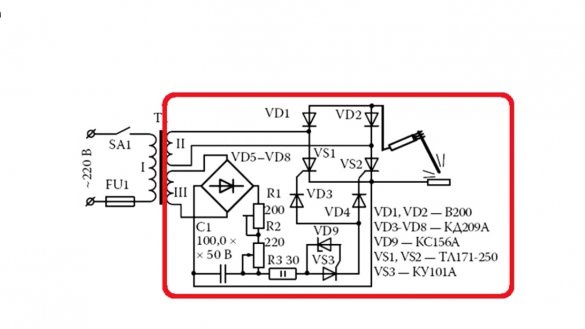

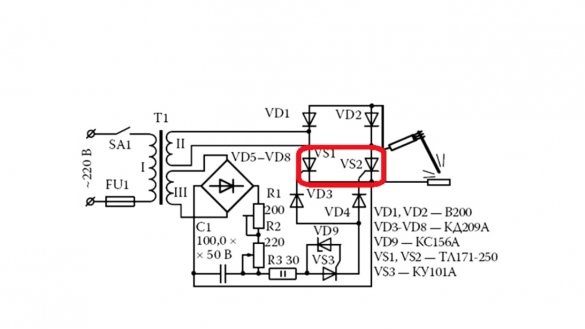

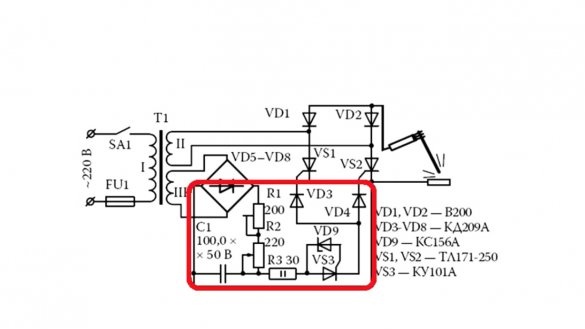

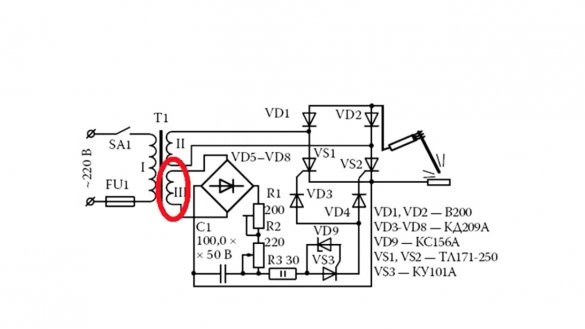

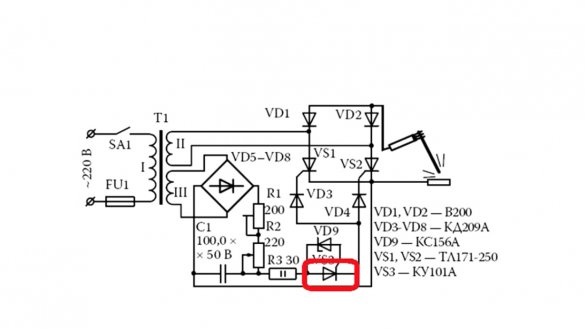

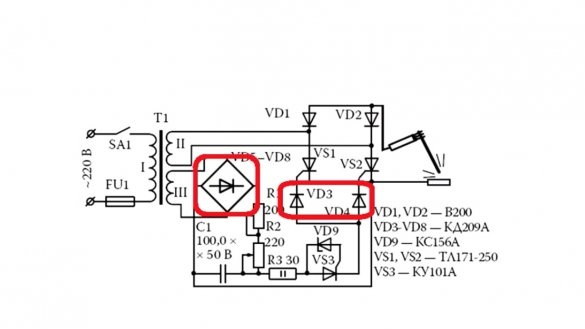

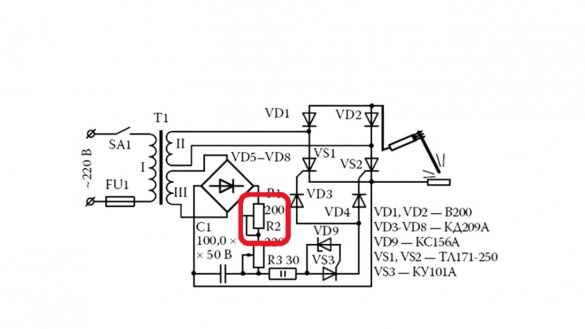

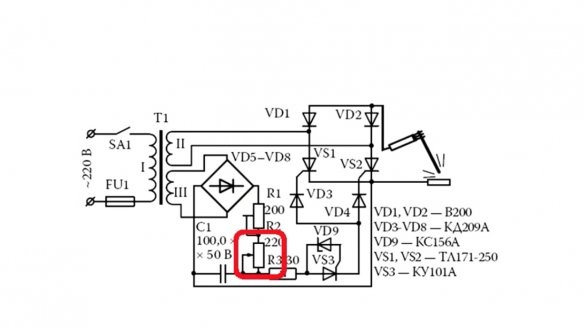

Below is a fairly well-known thyristor-based welding current control circuit:

The welding current can be adjusted in several ways, for example, with a load ballast or resistance, switching the taps to the primary windings of the transformer, and finally electronic adjustment method, performed, as a rule, using thyristors.

Thyristor-based current regulators are extremely reliable and also have high efficiency due to the impulse regulation principle. What is also important, when adjusting the power, the output voltage of the welding machine without load remains unchanged, which means that there will be confident ignition of the arc in any range of the output current.

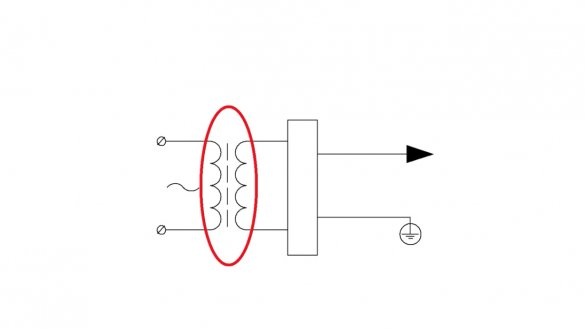

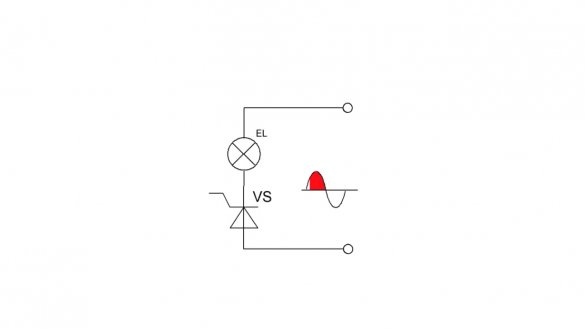

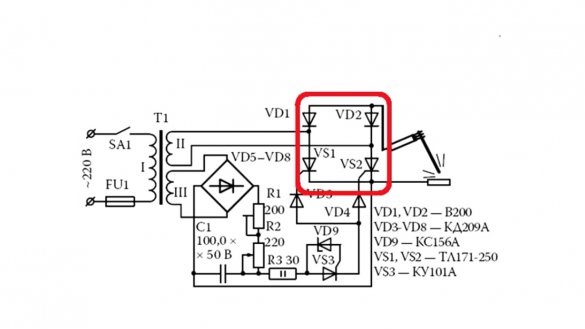

Power controllers can be installed as at the input of the primary circuit:

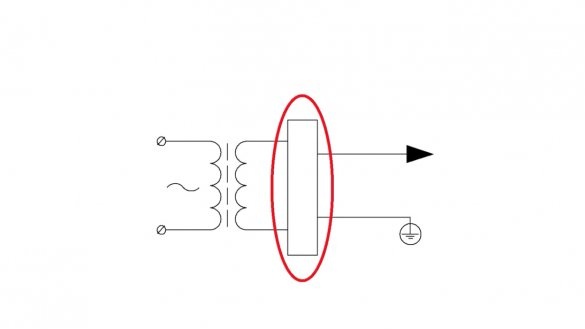

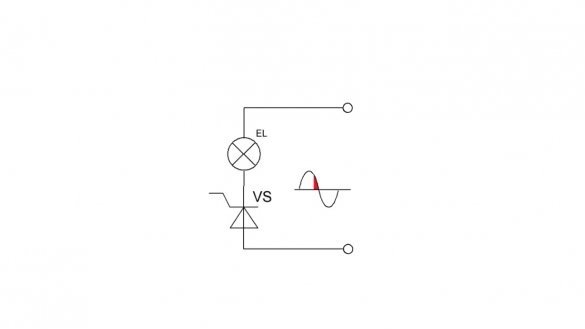

So at the output, after the secondary winding:

The problem is that the principle of power control using this type of controller is based on cutting off the initial sinusoidal signal, that is, parts of the sinusoid are fed to the load, and if the controller is installed on the primary circuit, irregularly shaped pulses will go to the transformer, which leads to the formation of a kind of sound, additional vibration and overheating of the windings.

But in spite of everything, these systems quite successfully cope with the inductive load, and if, moreover, there is a good and sufficiently reliable transformer at hand, then I think it's worth trying again.

In this example, the current control system is installed on a secondary circuit.

This allows us to control the welding current directly. In addition, such a system, in addition to adjusting the welding current, will also serve as a rectifier, that is, supplementing the welding transformer with such a regulator, you get DC welding with the possibility of adjustment.

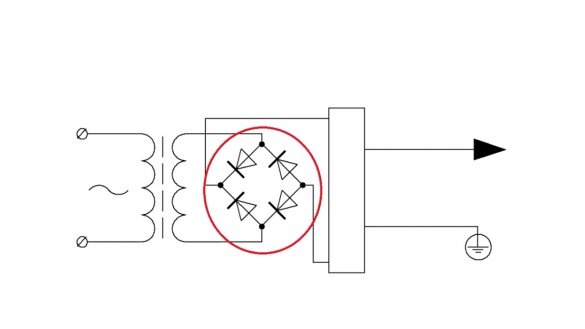

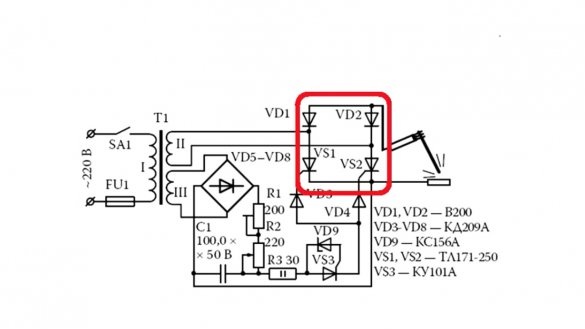

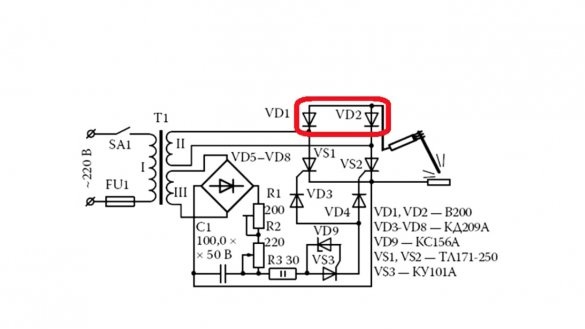

Now we will analyze the scheme of the future device in more detail. It consists of an adjustable rectifier:

It consists of a pair of diodes and a pair of thyristors:

Next is the thyristor control system:

The control system in this example is powered from a separate low-power transformer with a secondary voltage of 24 to 30V with a current of at least 1A.

Of course, it was possible to wind a winding with the necessary characteristics on the main power transformer and use it to power the control system.

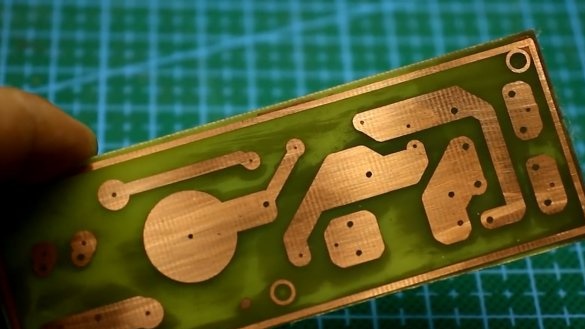

The circuit itself is made on a small printed circuit board. You can download it, along with the general archive of the project.

Thyristor can be used with any current of at least 1A.

In this example, the author used a 10-ampere, but this makes no sense, it was just at hand. The same with diodes, 1-amp is enough, but the current margin will never be superfluous.

The upper knob allows you to adjust the limits of the output current.

The second regulator is used to adjust the main welding current, here it is already necessary to use wire-wound variable resistors, preferably 10 or more watts.

Initially, the author installed this monster:

But then it was replaced by such a less powerful one:

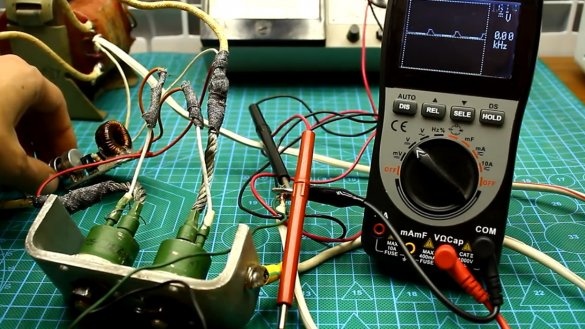

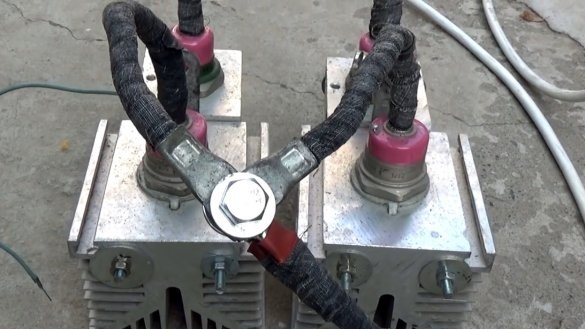

Now let's look at the power rectifier:

The diodes and thyristors used here, despite the monstrous appearance and excellent characteristics, were bought at a flea market literally for a penny.

These diodes are type B200 with a current of 200A, the reverse voltage also depends on the index. In this case, 1400V. But the thyristors are more powerful T171-320.

Such thyristors are designed for currents as high as 320A. The current in shock mode can reach up to 10000A. Of course, these diodes and thyristors are capable of more, and they will not burn out even at currents of 300-400A. And also these components were produced back in the USSR, that is, their characteristics are in no way inflated by the manufacturer.

The disadvantages of such a regulator can be attributed only to the large weight and decent size.

For all power connections, the author applied tinned copper terminals. Such can easily be purchased at almost any hardware store, they are not expensive.

Wires 2 to 6 squares in parallel, of course not enough, but they are copper.

The author found the electrode holder in the nearest hardware store, which was not very convenient of course, and the workmanship was poor, but what it was.

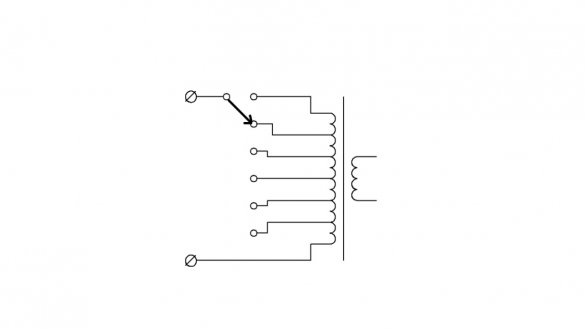

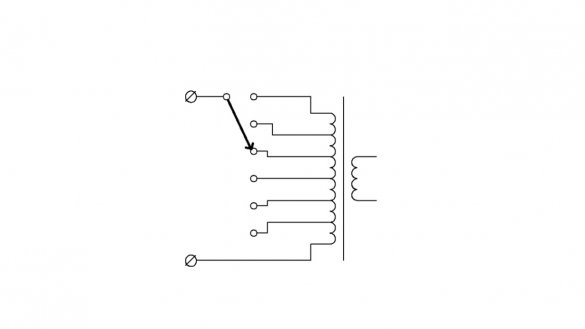

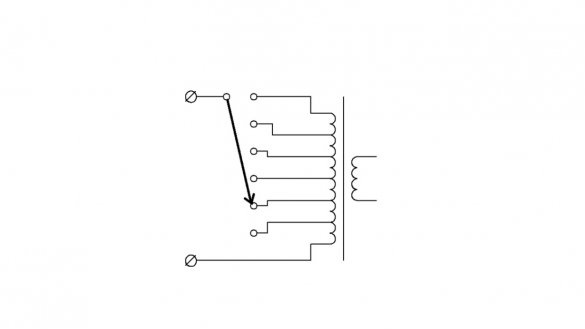

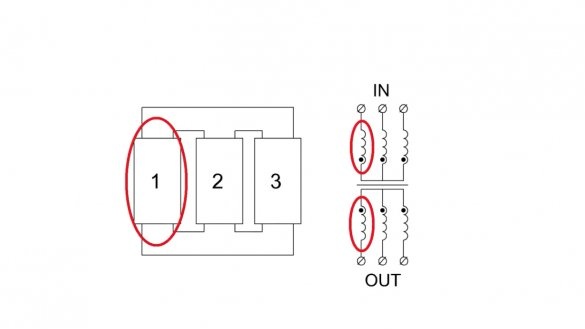

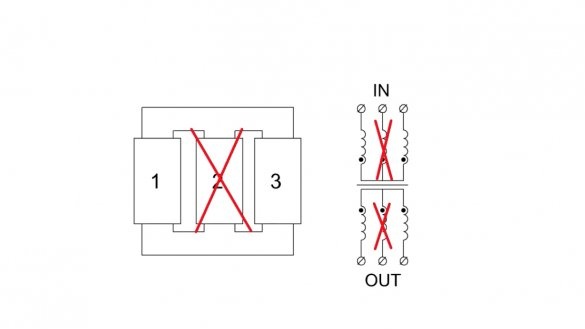

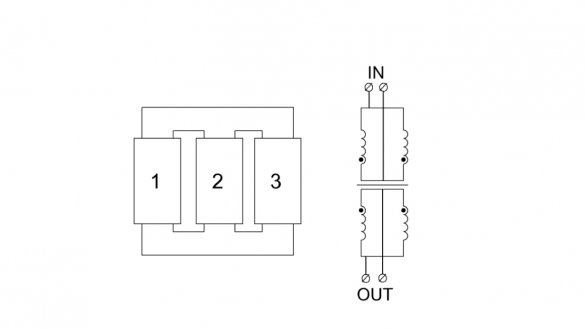

Now back to the transformer. Since we have a three-phase power transformer, and it will have to work in a single-phase network, we will have to switch the windings. Each coil has its own primary and secondary winding.

The author excluded the central coil.

Two extreme coils are connected in parallel, both on the primary and secondary windings for operation from a single-phase network.

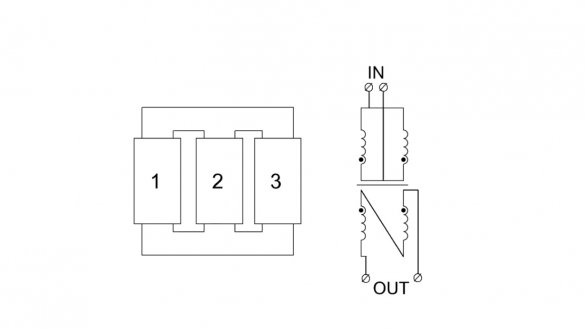

But during the experiments it turned out that, taking into account the losses on the rectifier, the voltage is not enough for the normal ignition of the arc, so the secondary windings had to be connected in series to increase the total voltage, the current would be 2 times less, but what to do.

At currents of 75-80A, this transformer begins to overheat and stink, and so the control system in this design can easily be used for currents of 200 or even more amperes.

After burning 3 electrodes, the author realized that the transformer was very hot, yet it was not intended for such tasks, but in this case we checked the current control system, and it works well.

That's all. Thank you for attention. See you soon!

Author's video: