I welcome fans to work with steel, today we will consider how to make a high-quality, stylish and strong knife, which the author called "Magma". The knife handle, like the sheath, is painted red, and the blade is made of high-quality hardened steel and has a dark color, which was obtained as a result of etching. The knife looks great, it also cuts perfectly. In addition to the belt sander, the author did not use any sophisticated knife making machines. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- hardened carbon steel;

- leather or other material for the sheath;

- birch suvel or cap for the handle;

- sheet brass or other metal for bolster;

- epoxy adhesive;

- stain of red color and oil for a tree.

Tool List:

- belt grinding machine;

- grinder;

- ;

- files;

- drill;

- sandpaper;

- ferric chloride for etching;

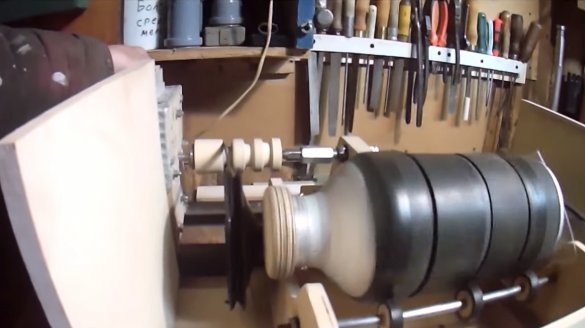

- tumbling machine;

- sewing tools.

The process of making a knife:

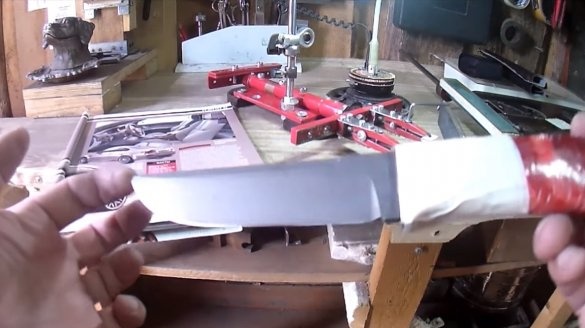

Step one. Blade. Primary profile

The first step is to find or buy a carbon steel billet, and the author’s steel is already hardened properly. If you know how steel is hardened, you can use files, car springs and other materials as material.

We draw a blade profile on the blank or make a template out of paper. Then you can start cutting, the author uses a grinder to work. You need to cut it slowly, the steel is already hardened and if we overheat it, the steel will become soft. We constantly cool the metal with water.

Step Two Grinding

Now the contour of the blade must be well sanded, remove cutting defects. We turn to the help of a belt sander and do not forget about constant cooling in water.

Then it will be necessary to make descents, drawing a center line along the future blade, which we will be guided by. If there is no special tool, the line can be drawn with a drill of the same diameter as the thickness of the blade.To form the slopes, the author used a special holder, it allows you to hold the blade at a certain angle relative to the sanding belt.

In addition, the author removed some metal from the butt, as a result, the blade looks quite interesting.

Step Three Manual processing

At the end, we grind the blade manually using fine sandpaper, we need to remove all the scratches. To make sandpaper work well, wet it with water or WD-40. The author managed to polish the blade to the state of the mirror.

Step Four Etching and Finishing

We lower a well-ground and low-fat blade into ferric chloride, as a result of the reaction the steel will become almost black. Do not hold the blade in the reagent for too long, otherwise shells may appear on the steel.

We take out the blade and wash it thoroughly under running water. In the end, the author sent the workpiece to the tumbling machine, as a result, a thin and thorough grinding of the blade was made. Now the blade has a light dark coating and looks great.

Step Five Handle assembly

For the handle, we need to make a bolster, it is classically customary to make it from sheet brass. We drill a hole in the plate and bore it with a file in the shape of a shank. As for the handle, we need a blank of suvel, burl, or you can use normalized wood. Such materials will look delightful, like the author.

Glue the handle blank with the shank with epoxy glue and leave the whole thing to dry.

Step Six Modifying the handle

We proceed to grinding the handle, we need to remove the excess wood and form the desired profile of the handle. The author does everything by eye, and the work is carried out using a belt sander. After rough processing, manual processing awaits us, in this we need sandpaper, hold the blade in a vise or clamp and get to work. Gradually reducing the grain size of sandpaper, we bring it to a perfectly smooth state. At the end, the author used sandpaper with a grit of 2000 units.

Now the handles need to be given the desired color, for such purposes we use a red stain for wood or another dye. We apply several layers of stain and after each new layer we carry out grinding.

At the end, immerse the handle in wood oil or varnish. That's all, now the knife is completely ready and it looks amazing. It remains to make a sheath for the knife.

Seventh step. Sheath

We make the sheath for the knife, the author chose a faux leather of red color, cut out a blank for the sheath and insert. Well, then the whole thing remains to be sewn, here we need a strong needle and pliers. To simplify the task, you can first drill holes with a thin drill, and then easily sew the sheath. Additionally, the joint can be glued.

Of course, you must remember to install the loop so that the sheath can be secured to the belt.

Step Eight. Completion

The knife is ready, it remains to sharpen it. For sharpening, the author used a special manual grinding machine with grinding stones. Such a stanochka is possible. As a result, the knife turned out to be ground to a razor condition. The made knife easily cuts thin paper. That's all, homemade ready, everything looks great. Of course, you need to use such a knife carefully, as it is very sharp and can be cut with carelessness.

This is the end of the project, I hope you liked the home-made, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!