A metal scraper can be used to finish the wood surface of parts. With the help of trial and error, the master made his scraper out of an old hacksaw. Consider what he did.

First, he dismantled the hacksaw, removed the handle from the blade.

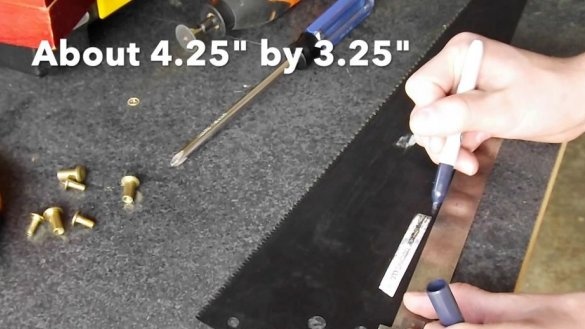

Marked out the shape of the scraper. Cut out.

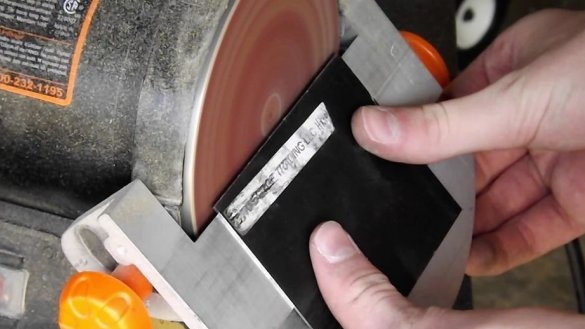

Then the master decided to sharpen one edge at an angle of 35 degrees.

After checking, it turned out that the tool does not work at such an angle, and then the master sharpened the blade at an angle of 45 degrees. From this angle, the tool began to remove chips from the surface of the board.

The upper corners of the scraper grind in a semicircle.

Grinds the surface of the scraper.

After the material was published on the instructables website, one of the masters left a comment that such a scraper does not need to be sharpened, it should be at an angle of 90 degrees. Sharpening the blade of the scraper, the master received a fully functional tool. Such a scraper performs the final grinding of parts, in the comments on the product, the master writes that, ideally, the working surface of the tool with an angle of 90 degrees should also be sanded.