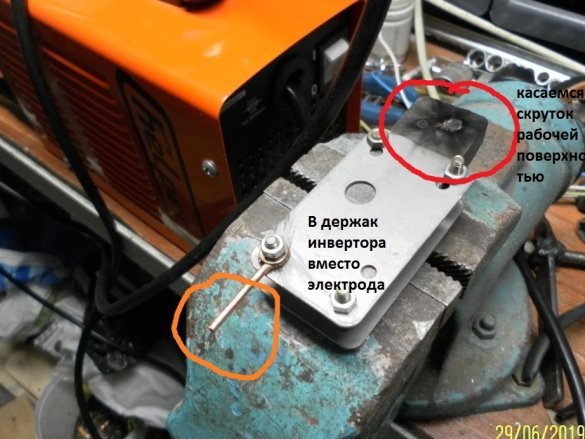

Good afternoon, dear "the inhabitants of our site"! I present to your attention device for welding electric copper wires, which works in conjunction with any welding inverter with current control. I was unbelievably lucky, because I found a carbon electrode near the trolleybus stop (yes, the one that slides along the contact wires). The matter remained small - to make a holder of suitable rubbish. For what? First: to ensure a good, reliable contact. The welding current was set experimentally on the order of 30 - 40 amperes. Secondly: the hands are not so dirty. Thirdly: the electrode itself is very fragile. He had to be protected with something, leaving only a working surface.

The principle of work, I think, is understandable. We clean the copper wires of 8 - 10 cm, make twisting. Clamp the “base” of the twist. We insert the fixture into the holder of the welding machine and briefly touch with the charcoal the tip of the twist, until a drop of welding appears. All! You will not find a more reliable connection. Simple and forever! I recommend for repetition!

I remind you: nowhere and never forget or neglect the rules of Safety!