Today we will try to make a detachable home-made circular saw with you, which, I think, no craftsman will refuse. The circular saw is easy to manufacture and the main components can be inexpensively purchased in a Chinese online store.

A circular saw is an electric tool with which to cut laminate, wood, wall panels, plywood, OSB, chipboard, etc. etc. Using this tool can significantly improve the quality of work and reduce the time spent on repairs or construction ...

Video instruction:

What do we need to make this tool?

Basic tools:

1. Electric jigsaw or hacksaw for wood.

2. Cutting machine with cutting and grinding wheels.

3. Drilling machine or drill.

4. A screwdriver.

5. Wrenches.

6. Knife for stripping wires.

Materials for making a circular saw:

1. Wooden blocks forty by twenty millimeters.

2. A sheet of plywood, with a thickness of at least ten millimeters (width and length are selected at your discretion, according to needs)

3. Copper, two-core cable, with a cross section of 0.5 mm square, about one, one and a half meters.

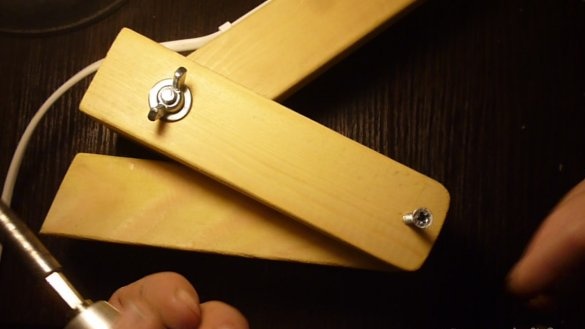

4. Normally open button, which will be at hand.

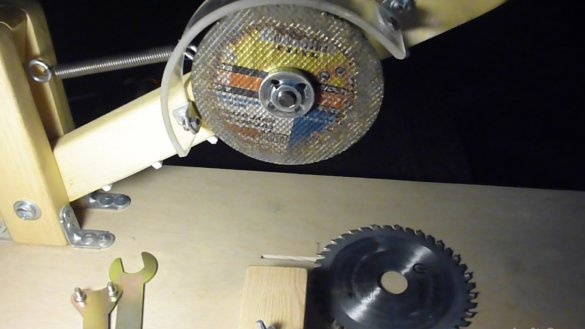

6. The electric motor, in our case, the 775 motor is taken (can be purchased in the online store), more in the video instructions.

7. The adapter nozzle on the engine for fixing the circular disk (can be purchased in the online store).

8. Circular disk (can be purchased in the online store).

9. Self-tapping screws, bolts, nuts.

10. Emery cloth.

11. Varnish or stain (Color of your choice).

We proceed to manufacture:

1. Measure the landing dimensions of the drive motor.

2.We will prepare the beam of the circular saw drive and the mounting rack on the desktop.

3. We assemble the electric circuit of the circular saw drive.

4. Assemble the design of the circular saw.

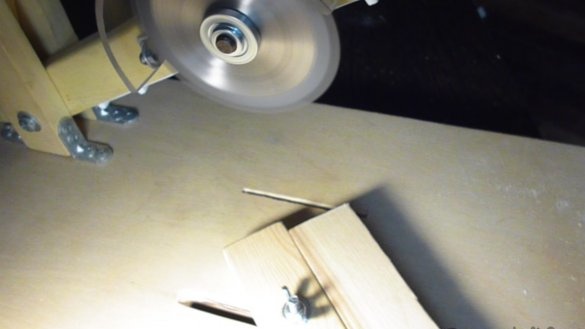

5. Install the circular saw on the desktop, fix.

6. We carry out control start of a saw.

7. We carry out control sawing of a wooden bar and metal trimming of the tube.

8. We use the tool with pleasure.

Of the positive characteristics of this power tool, there are three main ones: ease of manufacture, accessibility of materials and compactness.

CAREFULLY! The circular saw is a tool of increased danger, work with it carefully and carefully. Follow the rules and safety precautions.

Dear friends, write objective comments, based on your recommendations and comments, we will be happy to improve this version of the circular saw.

Good luck and success in the construction and repair.