I welcome fans to craft, today we will consider how to make a powerful pump from a grinder. The design turned out to be workable and the pump has great productivity, but the design has drawbacks and requires improvements. So, for example, there is no stuffing box in the pump, which means that the pump drives water into the Bulgarian gearbox, which is unacceptable and dangerous. The author also used cold welding “so that nothing would flow” in the place of attachment of the nozzle to the grinder, as a result, the nozzle was not removable. However, if you install a simple rubber gland and drain for water seeping through the gland (emergency), homemade it will turn out quite useful. Such a pump can pump water from the lake, water the garden and so on, moreover, the grinder can also be used battery-powered. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- ;

- cold welding;

- screws;

- a piece of pipe for the body;

- iron rod for the shaft;

- sheet metal;

- nuts and washers;

- long nut (for the thread of the grinder shaft);

- paint for metal.

Tool List:

- lathe;

- tools for threading;

- drill;

- grinder;

- welding machine;

- roulette.

Pump manufacturing process:

Step one. Housing

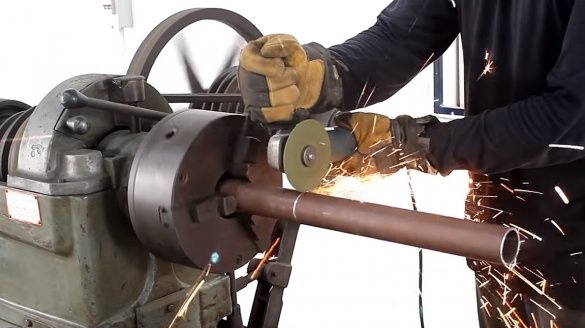

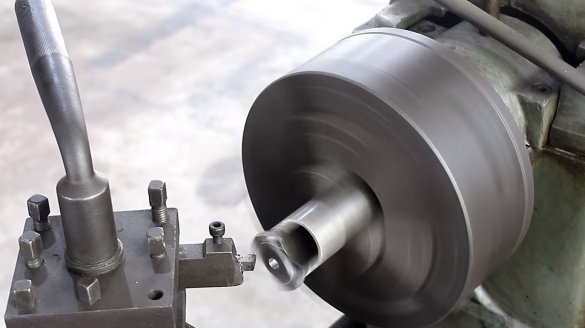

First of all, we will make the pump body, for this we need a piece of an iron pipe, the author cuts it with a lathe and a grinder, which is very convenient. Next, the pipe was polished to a shine using sandpaper and a lathe.

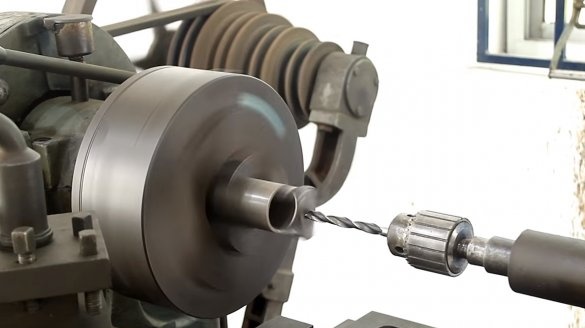

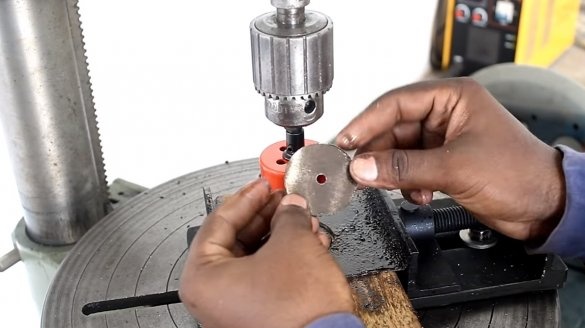

Now, in the lower part of the pump, you need to focus on the working shaft, cut the pipe as the author in the photo, to get a fork. We weld the cross member to this fork and then process the product on a lathe. In the center of the stop, we drill a hole along the diameter of the working shaft.

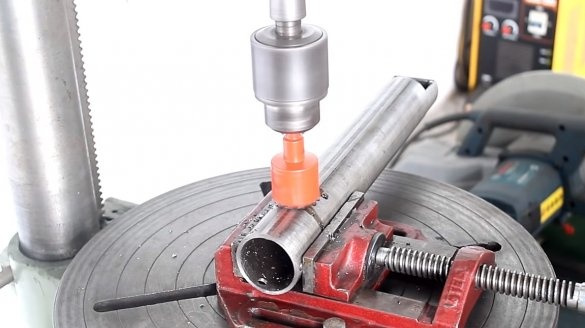

We also need to drill holes in the upper part of the pipe and thread the screws. Using screws we will screw the nozzle to the grinder. At the end, it remains to drill a hole in the body with a crown and weld the outgoing pipe. Of course, the weld should be airtight.

Step Two Working shaft

We will make a working shaft, for this we need an even iron rod, it is better to use steel, but it will be difficult to cut the thread on steel. The author has turned one end of the shaft so that a long nut is put on it, then this nut is welded, and it is needed to connect the working shaft to the Bulgarian shaft.

At the other end, thread the nuts to secure the propeller.

Step Three Propeller screw

Our propeller is made of steel and has four blades. To make a propeller, the author drilled a washer from a sheet of iron with a crown of a suitable diameter. Further, slots were made in the puck, and then with the help of two pliers, the author arched the blades.

Step Four Assembly and testing

All iron parts need to be well painted over with metal paint, otherwise they will quickly rust. Set the propeller on the working shaft and tighten with nuts and washers. We install a shaft on the grinder, and then install the shaft in the pump casing. The pump housing is screwed to the grinder.

Dangerously!

Of course, the lack of an oil seal makes homemade unsuccessful and stupid, but no one bothers you to do it, it's not difficult. And the pump works perfectly, the pressure is strong, and the height of the water column should be considerable.

Of course, you need to be careful, since the author has a grinder on 220V and if water gets into the grinder's nodes, an electric shock can be received through water! This is the end of the project, I hope you have found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!