Hello everyone !! Today I want to show you my next job. Do not judge strictly, I am just studying. For the manufacture of a knife, I found a knife from a cultivator with steel marking X12MF.

I'm a little smart. For the manufacture of the knife will go most of the steels, but you need to consider the peculiarity of using a knife. For a knife that will be used in an aggressive and humid environment, alloy steel grades are needed, that is, steel with an admixture of chromium, molybdenum, stainless steel and many more metals. All stop talking get to work.

For work, we need

- Tool

- Bulgarian

- Drill

- Grinder

- Hammer 1-2kg in weight

- Vise

- Sandpaper

- Maple cap for pen

- File

Here are my pieces.

Reinforcement is welded to the knives in the future, breaking off, I kindle my horn

I heat the workpiece and slowly cool to make the metal softer. I align the workpiece

I form a knife thickness of 2mm, forging with a yellow-white color.

I form a blade. Time is very short and therefore I whip up.

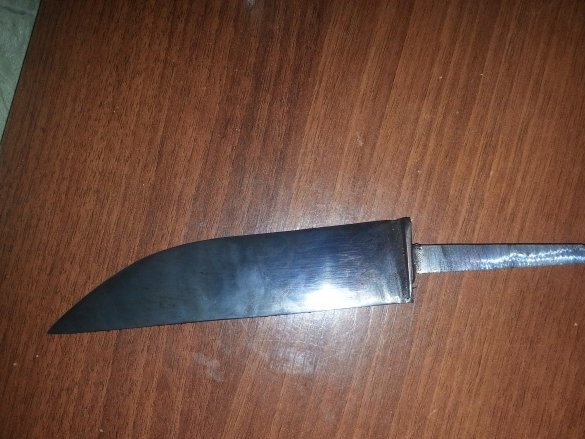

After the forging, I cut off the unnecessary ears. I forge preliminary descents and a tip and a shank

There will be no descent on my knife. From the butt, the blade smoothly goes to the point, grinding the blade

Preliminary work. I grind to a matte look.

I don’t sharpen the knife, otherwise the blade will burn during hardening.

I grind to a dull state

.

Quenching

I heat the knife, until it stops magnetizing, I dip in heated oil and so on a couple of times. Then I heat it again and dip it into water for surface hardening. I check on the bottle it scratches, it means it is tempered.

Now I send the knife into the oven for the holidays. I hold for 1 hour with a temperature of 400 ° C. Then let go to 300 ° C and hold for 2 hours, let go to 200 ° C and hold for 5 hours. Then let go to 100 ° C and hold for 10 hours. You will say that all this is tricky, but I don’t have a timer on the stove and the temperature is set, so I put down the knife, pressed the start button and I’m all resting. With this vacation, the knife becomes strong, but not fragile for a long time holding a sharpening. Here is the knife after the oven

Well, I proceed to polishing, moving from rough sandpaper to 2000ki, then polishing the goy with a paste. Unfortunately, I lost the photo of polishing.

I proceed to the handle.For the handle, I took a block of maple cap already dried, made a guard from a 1mm copper plate. On the front side with an oval I am punching a picture

After the copper, I put on the fiber and put a handle on the epoxy gulf. Now I am forming a handle on the grinder. Then I grind with fine sandpaper after I grind with wax.

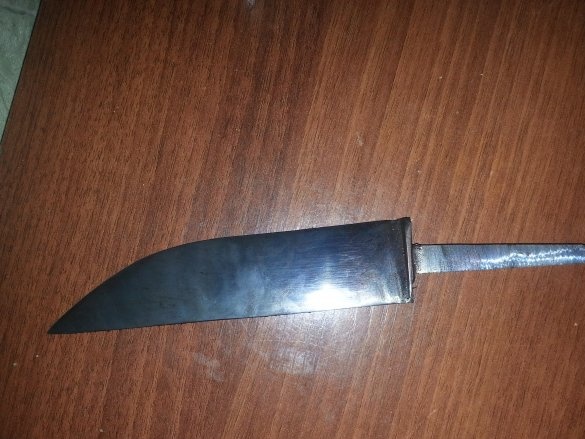

Well, that’s it, here’s the finished knife

Here is another photo

That's all, do not judge strictly, I'm just studying

Thank you all for your attention.

Until new homemade on our favorite site bestdiy.washerhouse.com