This material illustrates some of the modifications that the master made to digital calipers and other instruments to meet specific needs. Some modifications are reversible, while others are not. The master did not list materials or tools, because it will depend on the needs of each person, but he hopes that what is shown here will inspire others to take note of some ideas.

All modified tools were made to satisfy his need, not one was made simply “because it seemed like a good idea”. In most cases, photographs show everything you need to understand, and the text will be minimal.

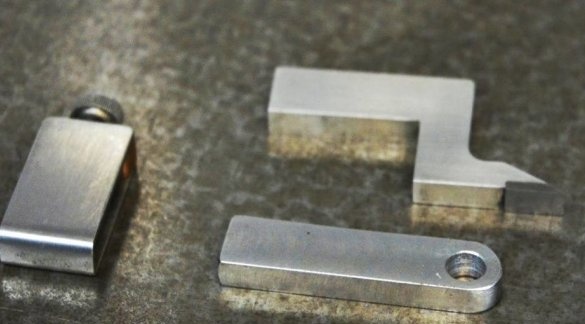

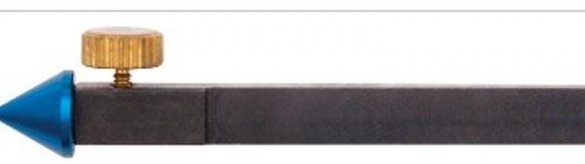

Shortening in length.

Sometimes calipers are simply too long to fit in a confined space. Shortening them does not affect functionality. Remember that you must also cut the rod of the depth gauge, or this will increase the length when you open the caliper. The craftsman drilled a hole near the trimmed end to install the stop screw.

Circumcision of external sponges.

Continuing the theme of installation in confined spaces, the outer measuring jaws are cut off from this bar.

Grinding the outside.

In this modification, the outer edges of the outer jaws are sewn down.

Grinding the inside

Here, the master grinded the inside of the outer and inner jaws without touching their very edges. Those. functionality will be the same.

Barbell for brake discs.

Calipers are different. This caliper is for measuring the brake discs of a car. The master added a screw to each sponge.

Height meter.

Another measuring tool. Here, as in the previous case, the wizard adds a screw. In the first two photos, the work of the master, the last photo is an industrial version.

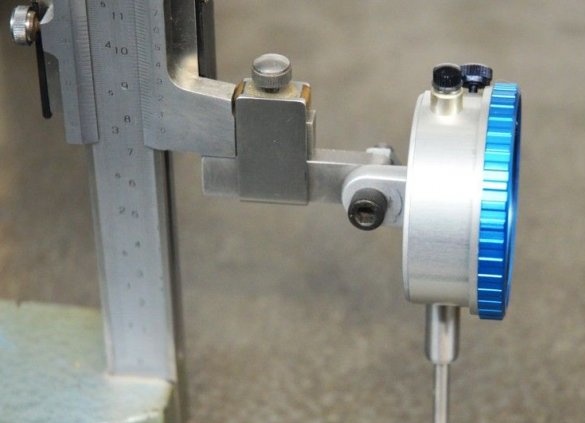

Adding an indicator.

In the next modification, the wizard added a dial indicator to the height meter.

The video shows the operation of a digital indicator.

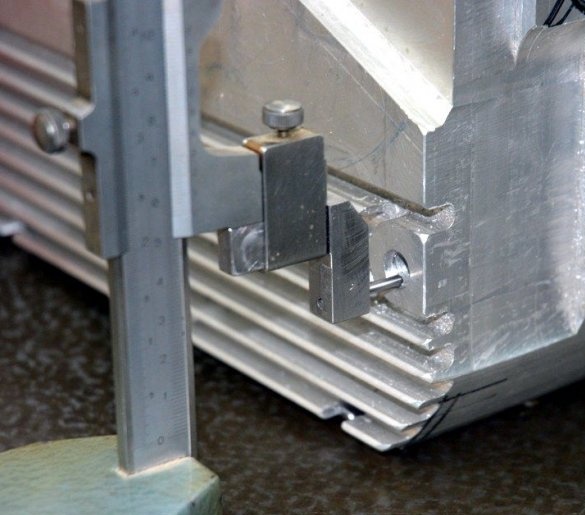

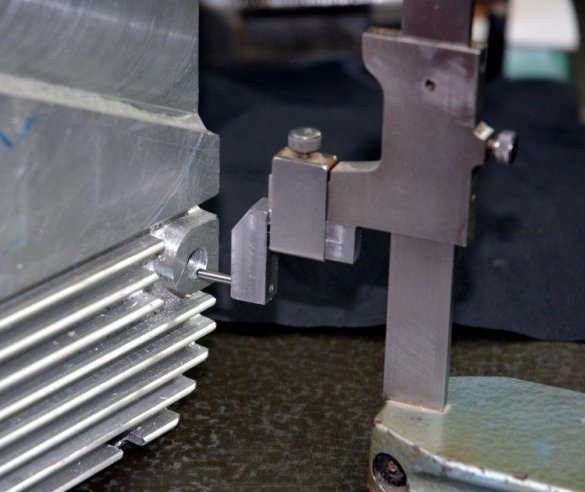

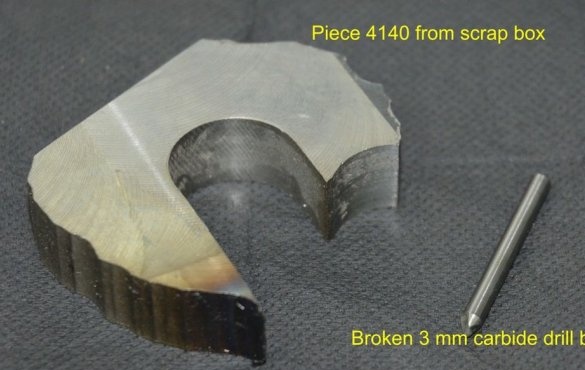

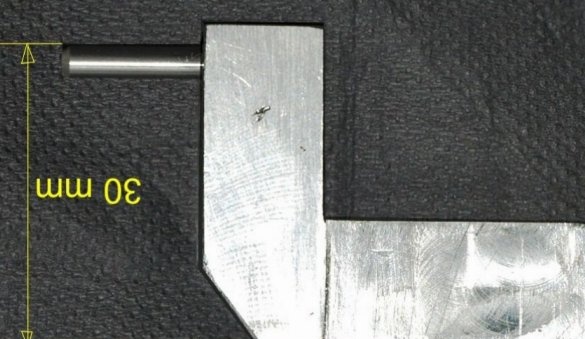

Height meter again

This improvement helps with measuring narrow vertical slots or holes.These measurements can also be made using a cone, but the holes are not always round, and this can cause inconvenience to the measurements.

Own device the master made a piece of metal and a broken drill.

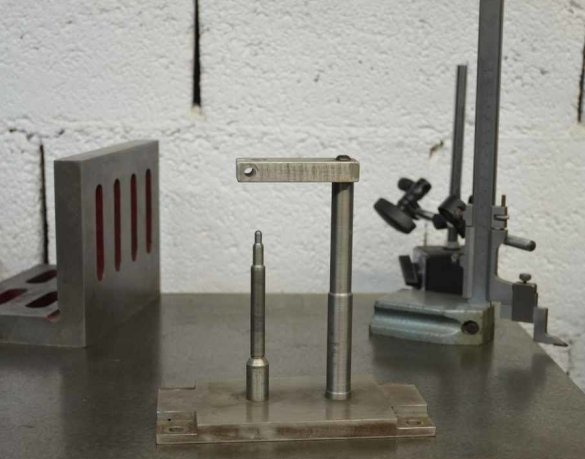

Device for measuring the walls of the piston.

The master made the following device specifically for measuring the walls of the piston.

That's it. Perhaps this article will be useful to anyone.