There have already been a lot of vacuum cleaners, here is another one performed by Instructables under the nickname Chialiang. The design is made of a hair dryer - not building, but one that is for hair.

The hair dryer motor is often powered by a tap on the heater. If the heater burns out, then, depending on where it burned out (before or after the exhaust), the engine either fails from the increased voltage or simply stops. In the second case, you can make a vacuum cleaner from a hairdryer, for this you need to remove the heater and the remaining components that have become unnecessary, reverse the engine and power it up with the voltage for which it is designed, and add a filter to the design.

Motors in hair dryers are asynchronous, universal commutator, as well as DC commutator. In the third case, a diode or diode bridge is used.

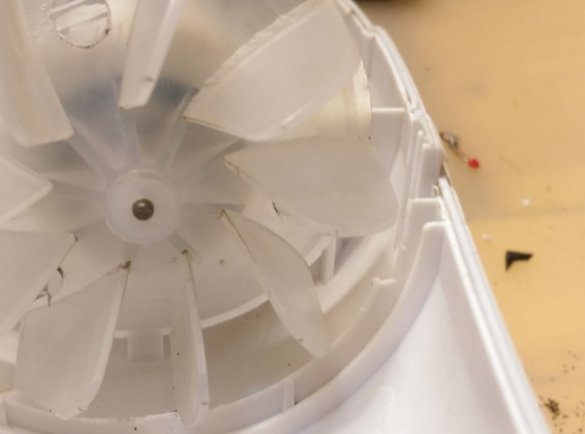

The master parses the hairdryer:

Look carefully at the engine: the diode bridge is wired directly to it:

You can solder the bridge output from the motor terminals, and then solder in reverse polarity. But the master decides to change the direction of the air flow in another way. Compare these two photos:

But now the protrusion on the casing prevents the impeller from rotating:

The master cuts it:

Another such metal part interferes:

Which the master removes:

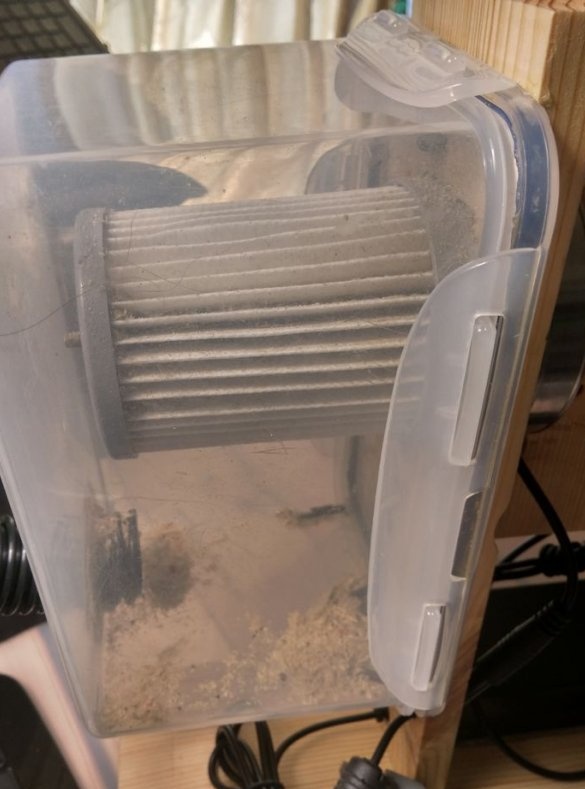

Now he takes a plastic jar for sandwiches and a wooden board:

Fastens the can lid to the board:

The lid was originally a little cracked, the master closes the crack:

But then he decides to cut out the entire fragment with a crack. And in the board drills holes for the passage of air from the container into a converted hair dryer. Or - rarefaction from the hair dryer to the container. Mathematicians will say that they are one and the same. A small diameter hole in the center is used to secure the HEPA filter.

Installs a cylindrical HEPA filter:

Fixes it:

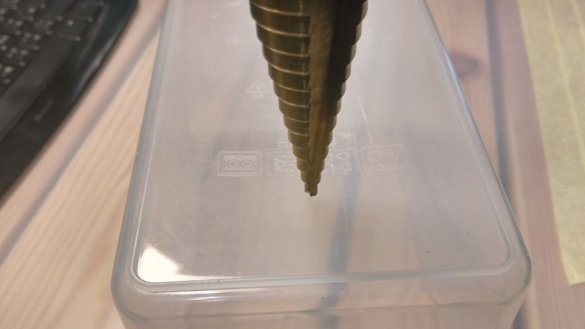

A step drill, also known as a carrot, drills a hole for the hose, the main thing here is not to miss the step, otherwise the hose will have to be connected through an adapter of a larger diameter:

Installs a hose:

Glues it with hot glue:

The master takes over the manufacture of the holder for the hairdryer, for which he takes another plaque. Traces a shadow cast by a hairdryer:

With such a tool:

It processes the plank along the contour of the shadow, and then attaches it to the base:

Drills holes in the resulting hair dryer holder in which the hair dryer is fixed with two clamps through gaskets so that it is directed directly into those four holes for air passage:

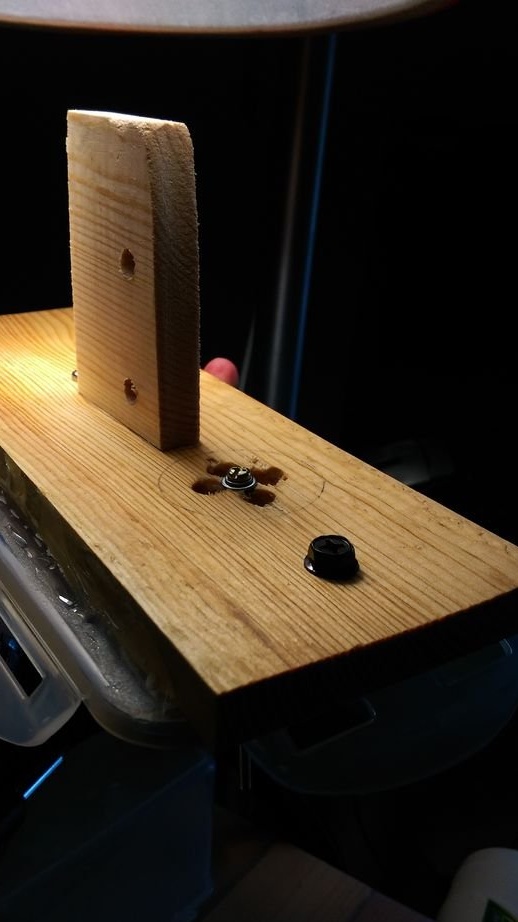

The vacuum cleaner is ready, it remains to apply power to it. The master takes a PWM controller, disassembles it, drills a hole in the lid, threaded a bolt:

Collects it and fixes it this way (you need to make sure that the bolt does not touch the regulator board, otherwise it is possible short circuit):

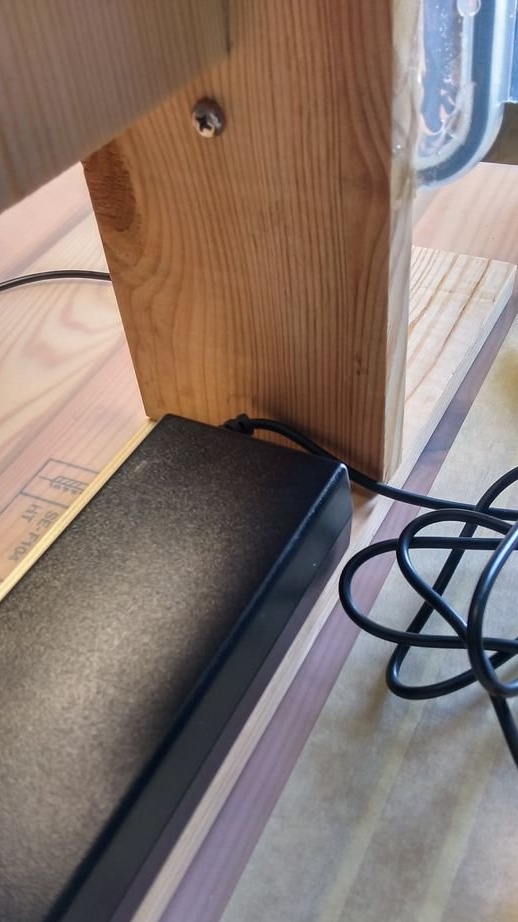

Adds a laptop PSU (19 V for a 24 V engine - even not enough):

Which sticks and withstands pressed clamps until the glue dries:

It connects the PSU output to the input of the regulator, observing the polarity, and the output of the regulator to the input of the bridge on the motor - in any polarity. The vacuum cleaner is ready, so it works:

Low power does not allow the vacuum cleaner to lift hardware from the table. After several days of work, a lot of dust gathered in it: