Surely each of you has its own secrets, and to protect them, various types of locks and locks are required.

In this article, the author of the YouTube channel “my mechanics” will tell you how he made a small code lock.

Materials

- Stainless steel bolt

- Brass round timber

- Ferric chloride

- Double-sided tape

- Nail polish

- Sandpaper

- Steel wire 0.3 and 0.8 mm

- Steel balls 2 mm in diameter

Instruments, used by the author.

- Lathe

—

- Belt sander

- Drilling and milling machine

- Polishing machine

- Vise, hacksaw, marker, file, files, nippers, tweezers.

Manufacturing process.

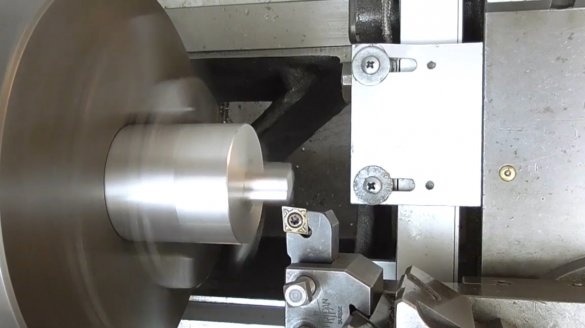

So, as the main material for the lock, the master chose a stainless steel bolt. Of course, to reduce the number of turning operations, a steel bar and a plate are better suited. But the author did not find such.

To begin with, he cut the head of the bolt in half, put both parts aside, and cut the thread from the remaining part. It was divided into two cylinders.

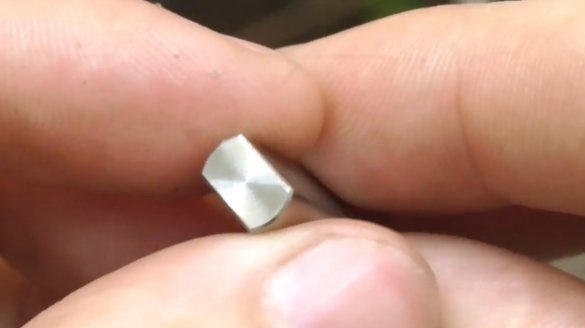

Each cylinder was cut lengthwise with a hacksaw. In the end, these are the blanks.

Marked one of the halves of the head, and glued both halves together with double-sided tape.

Stoch the unnecessary parts on a belt sander, and leveled the plane.

Then he drilled the necessary holes in them, and divided the workpieces.

For subsequent processing, I installed these fungi in the holes, they will serve as a guide when grinding the contour.

I expanded the holes in the workpieces, and countered them.

On a wide part of one of the blanks, I milled holes for the ball. After polishing on the machine, the details look like this.

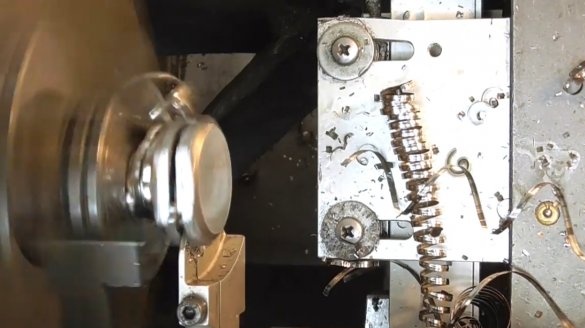

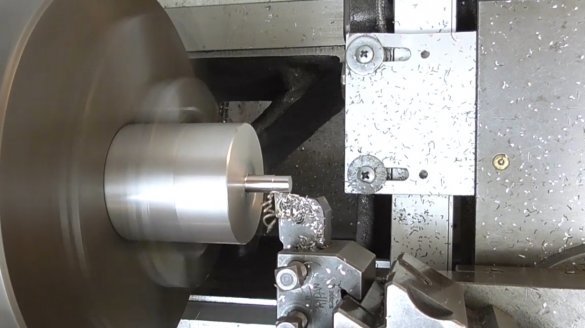

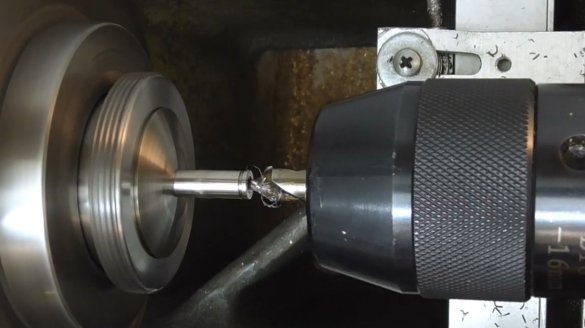

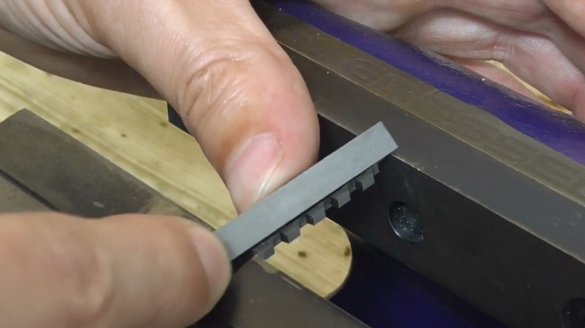

Now from the halves of the cylinder you need to make the rest of the elements of the castle. He clamps the workpiece in a special conductor.

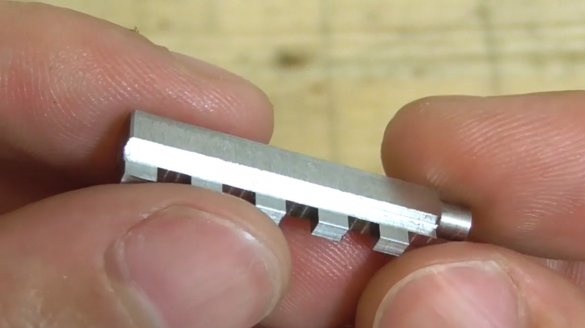

Then he grinds four such blanks.

The first part will be a hub for digital wheels. The master turned it to a cylinder shape. A shallow groove for the latch cut through on one of its edges.

I drilled a hole in the workpiece, turned it around, and made a small groove of the second end. Why it is needed will become clear later.

This is the first detail of the mechanism.

Now you need to mill in it a groove for locking teeth.

A groove was needed so that the part did not fall into the hole, but was fixed in it at a certain depth.

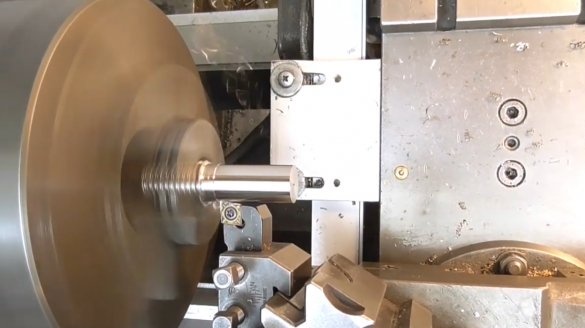

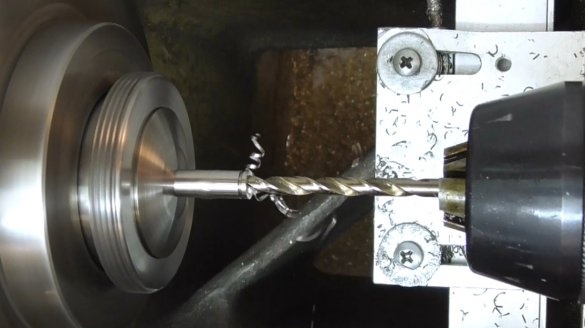

According to a similar scheme, a guide with a hole inside is made.

Now it can also be installed in its place.

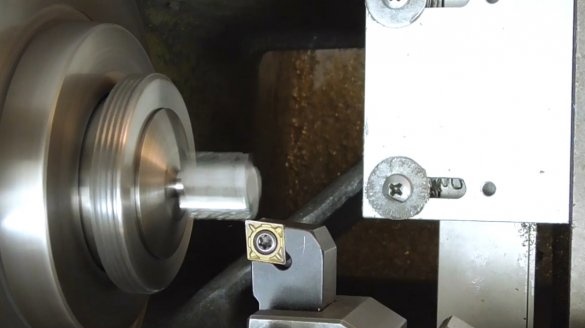

The next part is one of the most difficult in this project. To process it, you need to shift its center using the lining.

After processing, we get such an offset ledge.

The sides of the part are machined on the router.

Then a small lateral groove is made, and the milling of the teeth.

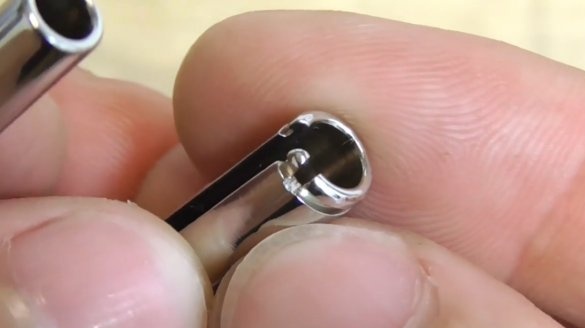

Here is such a clever blank of the locking mechanism.

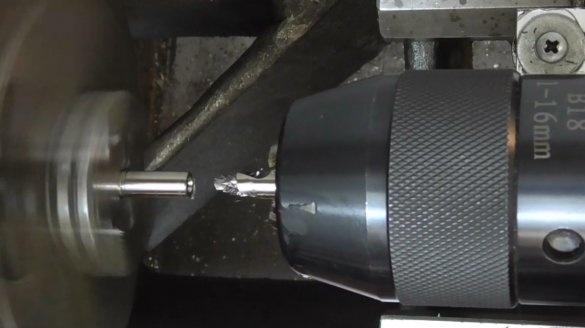

Now it needs to be processed with a file and a file, rounding the edges of the teeth.

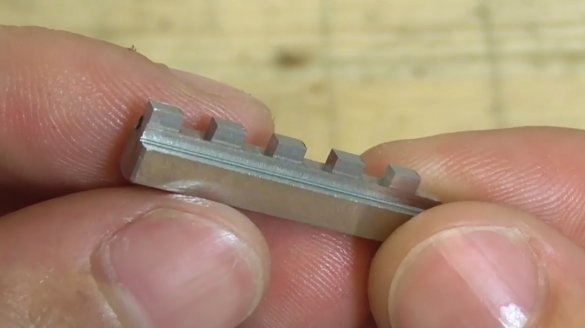

After sanding and polishing on the machine, the part is ready. It is installed in the second side of the castle.

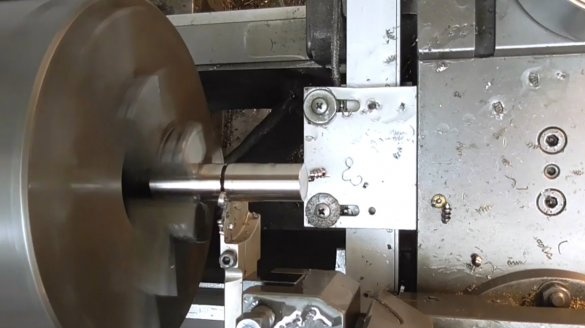

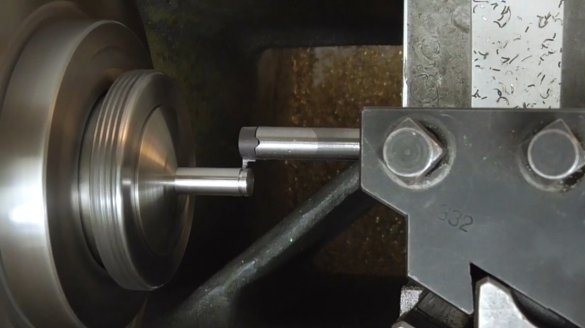

There remains the last hairpin with a rounded nose.

Grinding, polishing, and reinstalling again. Now both parts of the lock are ready for welding.

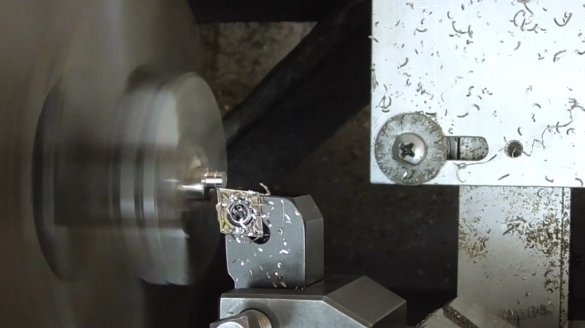

The master welded all the studs to the side parts.

Both parts will not be processed anymore, they can be polished completely.

The master forgot only one element, this is a slot for fixing the latch.

That's how they connect together.

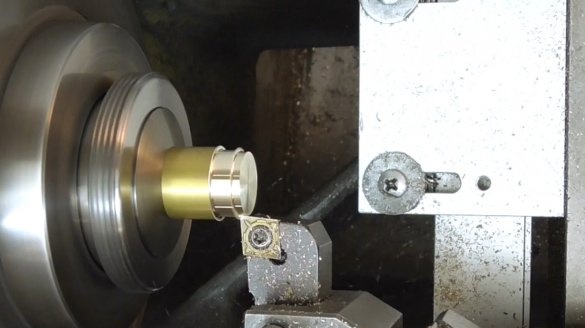

Now it's time to make the rings. The author decided to make them from a brass bar.

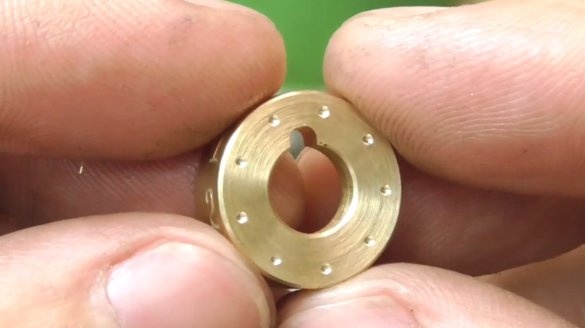

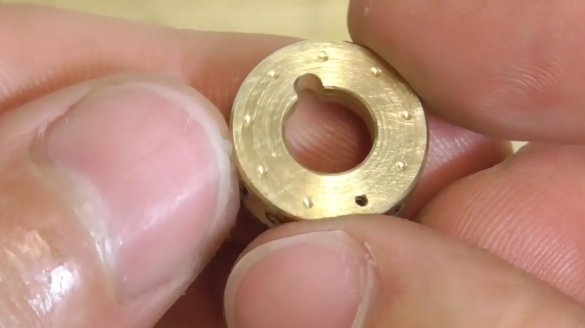

He carved four identical rings, and one with a flat side wall.

On the laminated paper, he printed the numbers in a mirror form, and cut out strips. To do this, use a laser printer. The bands are fixed on the outside of the rings.

Now he warmed the paper with an iron, and the numbers transferred to the surface of the metal.

Next, he needs to protect all exposed areas of metal (except the numbers themselves) with nail polish.

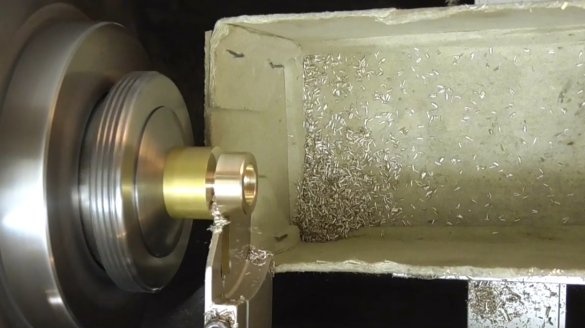

After the varnish has dried, it places the workpiece in a solution of ferric chloride for 45 minutes.

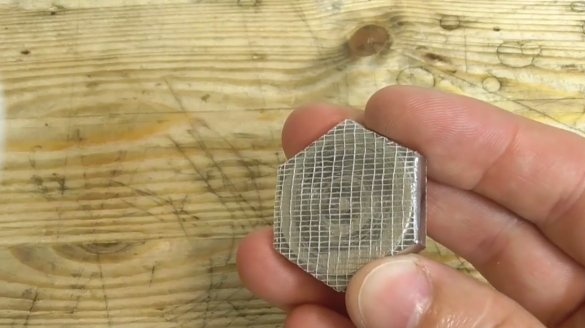

And here is the result of etching. The surfaces can now be sanded.

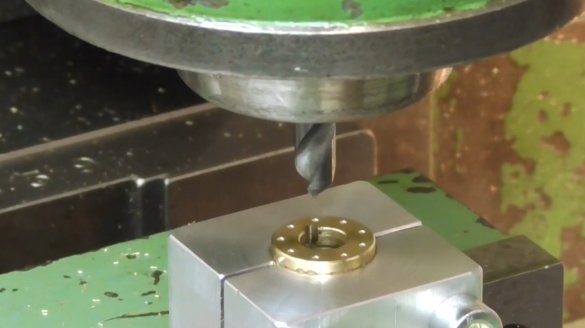

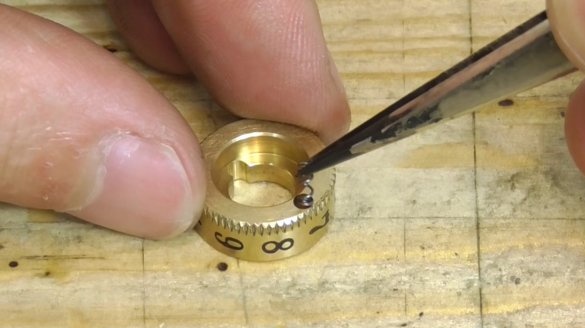

In the central part of the rings, the master cuts a groove for the teeth in accordance with the code digits he needs. Also, holes for balls are milled on the first four rings.

For the convenience of using the rings so that they do not slip in his hands, he makes knurling at one of the edges.

On the one hand, it drills a through hole of 0.8 mm, and on the second - 2.1 mm, but not to the very end.

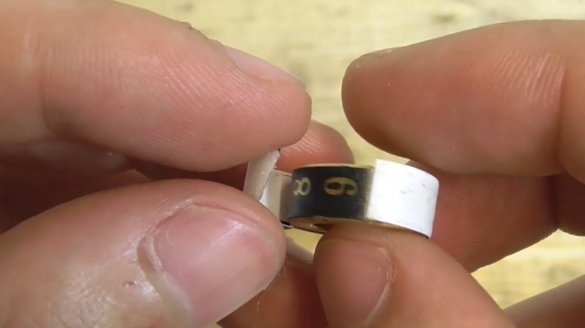

Now the numbers are filled with varnish for contrast, and after drying polishes all surfaces.

So, the wheels with numbers are ready!

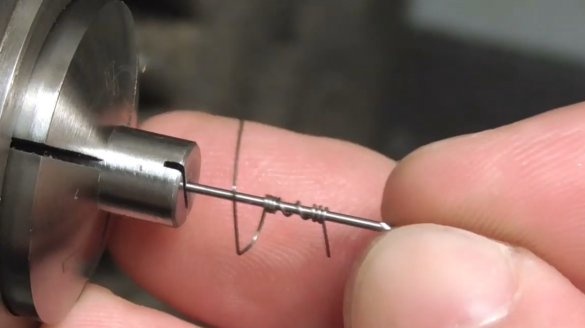

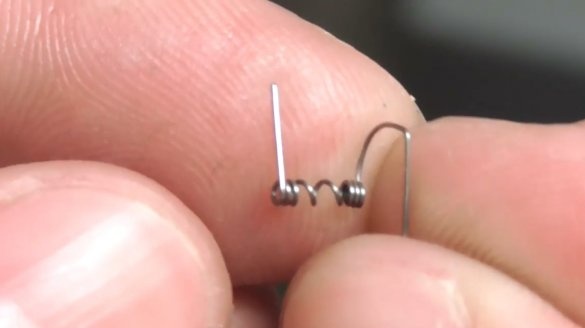

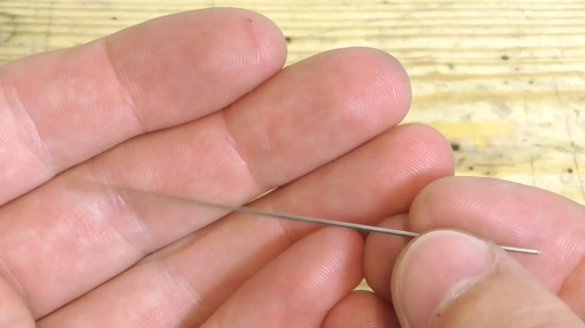

Then the master needs to make hold-down springs from 0.3 mm wire. Balls with a diameter of 2 mm are also required.

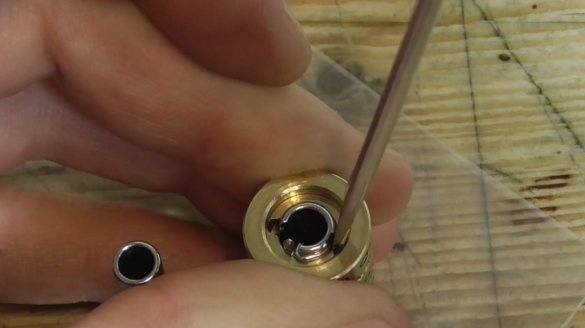

Installs springs and balls in place.

And makes a trial assembly of the lock mechanism.

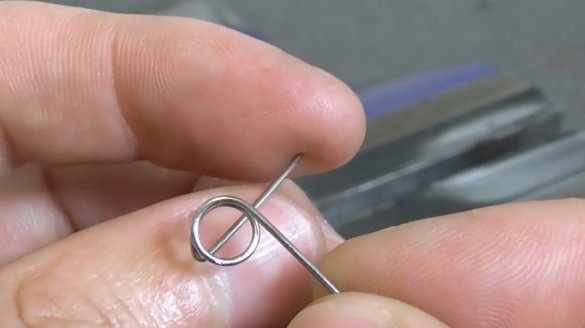

Now he needs to make a drum retainer from 0.8 mm wire.

Establishes a clamp in place, and latches it in a groove.

So the castle is ready! Now you need to install the correct code, and insert the response part. After that, you need to knock down the cipher, and the lock will close. It is enough to turn even one wheel.

To open the lock, the correct code is simply set, and everything opens easily. Most interesting, the master made the wheels without the number "0", so the combinations will not be 100,000, but only 59,049. But it is also a very, very long time to open. If desired, you can increase the number of wheels. Such a small lock is well suited for travel bags.

Thanks to the author for the very unusual idea of a high-quality combination lock!

All good mood, good luck, and interesting ideas!

Author video can be found here.