Today we will talk again about the circular saw, which is quite capable of making at home. The basic manufacturing option of our circular was set out in an article posted at: Do-it-yourself cutting circular saw

For those who are not too keen on the question of what a pendulum circular saw is. Let us explain in a nutshell. A wood circular saw is electrical equipment where the main cutting tool is a saw blade. In addition to the machine with a fixed disk, the pendulum circular saw also falls under the concept of “circular saw”. It differs from the classic circular saw with a fixed disk, the mobility of the working disk, which is fed to the material fixed for processing.

Let's try to slightly change our circular saw. And due to the change, we will achieve a significant increase in the functionality of this equipment. Namely, the installation of the working longitudinal stroke of the cutting tool, in our case, the longitudinal stroke will be approximately 350 mm.

A home-made pendulum mini circular saw, subject to accurate and proper assembly, will always perform high-quality sawing of your material and will have a service life that is almost the same as for factory-made models. When replacing a circular disk with a cutting one for metal, the saw can work perfectly also for metal.

As we mentioned in the last article, purchasing this equipment is quite expensive and if you are not a professional builder, it makes sense to manufacture, this machine for their needs, in home conditions, in the end we get a budget version of a good machine for home use. To make a pendulum mini circular saw is completely uncomplicated, the novice home master can cope with the task by focusing, at work, the main attention to the accuracy and accuracy of manufacture. We made, as usual, a test version of the product. T.ch. you select the sizes and material according to your capabilities and needs.

According to the materials:

You can find wooden blocks, buttons, electric cables, screws, and bolts in any hardware store or your the garage. Three parts, an electric motor, a circular disk and a shank on the motor shaft, can be purchased in the online store, a link to these details we will place under the video clip posted on the YouTube channel.

IMPORTANT! When working with this equipment, you must strictly observe the safety rules and requirements that are prescribed when operating tools with increased risk. Take care of your health ...

Video instruction:

So let's get started.

Tools for making a pendulum mini circular saw:

1. Hacksaw for woodwork

2. Electro jigsaw

3. Electric drill

4. Screwdrivers

5. Wrenches

6. Cutting machine

7. Sandpaper

7. Joiner's knife

8. Vise

9. Good mood.

Materials used for our circular saw:

1. Wood blocks, better than hardwood

2. Plywood with a thickness of 10 mm

3. Electric motor, out of your needs and capabilities. We took a 150-watt motor, for a mini circular saw it was enough.

4. The circular disk

5. Shank on the engine to install the circular disk

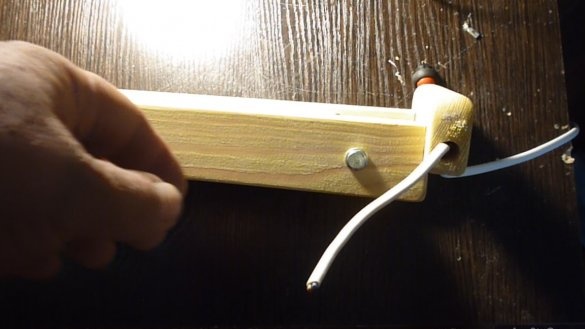

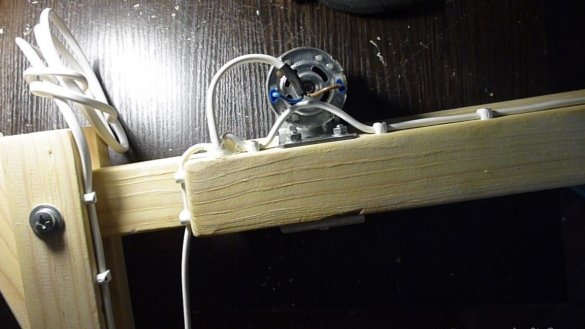

6. Electric cable

7. Furniture guides two pieces

8. Button

9. Stain

10. Bolts, screws

11. A small segment of an aluminum tube.

Manufacturing process:

1. We prepare the bars, as shown in the video instructions.

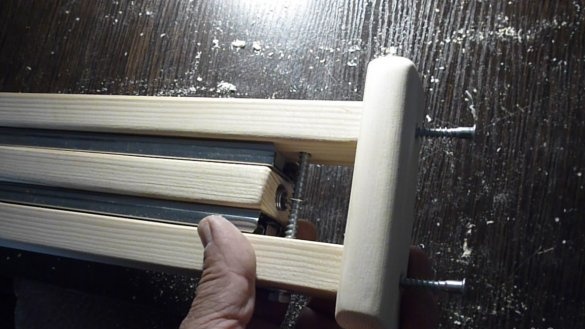

2. We assemble the beam of the machine, a composite of a fixed and movable part having a stroke of 350 mm due to furniture guides placed between the fixed part and the movable.

3. We make installation of an electric circuit with an electric motor and a button.

4. We put a protective casing in a regular place.

5. Install the lever on the rack.

6. The resulting mechanism is fixed on the bed.

7. We connect electricity.

8. Test run circular.

9. Control cut.

10. Operation.

Our mini circular was made on the knee and purely from the head incl. It has a number of minor flaws that were discovered during the manufacturing process. In the following articles, we will make small changes and additions to the design for better and more convenient work with this equipment. If you, dear friends, have any thoughts on improving or changing our pendulum saw, we will be pleased to take note of them and introduce them into the design if this will improve this tool.

Good luck in the construction and repair!