In this article, Andrey, the author of the Shayter Andrey YouTube channel, will tell you how he made a holder for canvases from a reciprocating saw and an electric jigsaw from simple and affordable materials.

Materials

- Anchors, wood screws

—

- PVC pipe with a diameter of 20 mm

- Sandpaper.

Instruments, used by the author.

—

—

-, cutting disc

—

—

- Roulette, marker.

Manufacturing process.

So, Andrey acquired several anchors 145 mm long and 10 mm in diameter.

Now he needs to mark out the future groove. On the one hand, it should be 25 mm long, and on the other 35 mm.

He presses the workpiece to the workbench with a clamp, and makes a groove obliquely with a grinder.

Places to cut, and the slot itself is polished with a strip of sandpaper.

Then the master puts a mark on the end, which will indicate where the deepest side of the groove is.

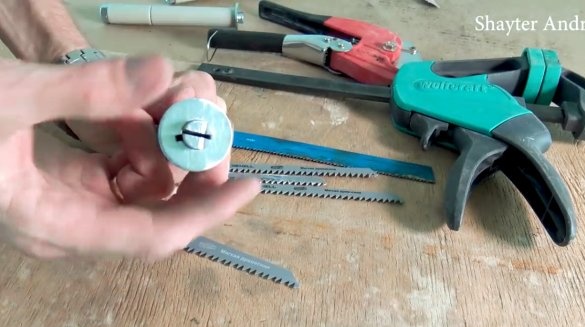

It fixes the washer from the anchor on the workbench and makes a slot 2 mm wide and 3-4 mm deep. He did this with a jigsaw with a metal sheet, the same work can also be done with a file.

The inner hole of the washer is a kind of cylinder. For better pressure, the master bores it to a conical shape.

Now you need to apply a small notch on one side of the nuts from the anchors.

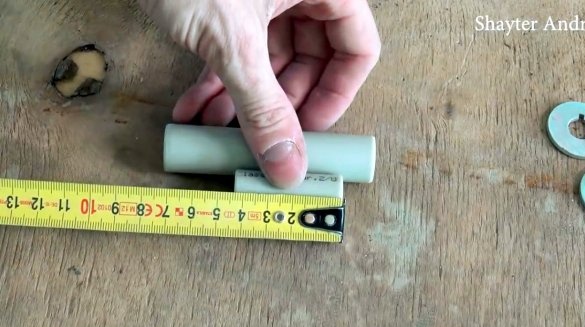

Next, you need to cut several blanks for the body, for this, a PVC pipe with a diameter of 20 mm is perfect. The blanks will be 45 and 85 mm long, respectively. These sizes are suitable for the anchor that the author uses. For cutting, special scissors for PVC pipes. Of course, you can use the usual hacksaw.

From one edge of the sleeve from the anchor, it slightly extends the edges.

Then inserts the sleeve into a short tube.

Now he puts the washer on the bolt from the anchor so that its bored edge falls on the flared side of the bolt. He puts a long piece of pipe on him.

Extends the sleeve from the second side.

And connects both parts of the tool together. Tightens the nut with the notched side to the plastic pipe.

The master also recommends that the flared part of the bolt on both sides near the slot is slightly sharpened. In this way there will be less likelihood of jamming the puck.

So, the handles are ready, you can try installing the blades.

First, he clamps the blade from the reciprocating saw in the handle. The washer expands to the desired position, the blade is inserted, and the handle is tightened. In this case, the long part of the shank enters the handle according to the mark, there is a deeper groove. To clamp the saw, it is enough to turn the parts of the PVC pipes relative to each other.

To install a file from a jigsaw, the washer rotates the slot to the side. The inclination of the blade relative to the handle is regulated by the immersion depth of the shank into the groove.

Now a few files are ready. Moreover, the blade can continue to be used in a jigsaw, or saber saw.

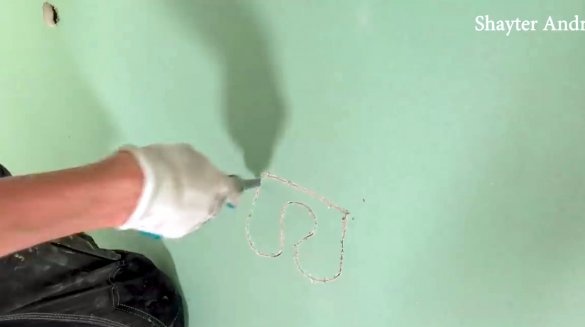

This is an example of curved drywall carving with a jigsaw blade.

And with such a cloth on aerated concrete it is convenient to trim such structures here. This is useful for cutting mounting foam flush with the surface.

Even very small canvases can be clamped into this handle. Andrei did not try to achieve an ideal appearance, he wanted to show the basic principle of creating such fixtures.

Thanks to the author for a simple but useful tool for the workshop and construction!

All good mood, good luck, and interesting ideas!

Author video can be found here.