Hello to all amateur craftsmen, I propose to consider instructions for the manufacture of a pneumatic sound signal for a car. Using this technique, you can make a signal of almost any volume, and you can also customize the sound of your car just for yourself. In assembly homemade not complicated, it uses a 12V car compressor and a receiver as the basis for which the author adapted cases from fire extinguishers. The receivers are filled with air to a certain pressure, and then the compressor automatically shuts off. An audible signal is heard when the electric pneumatic valve opens. If the project interests you, I propose to familiarize yourself with it in more detail!

Materials and tools used by the author:

Material List:

- ;

- an electric pressure sensor (which controls the compressor);

- emergency relief valve;

- pressure gauge;

- corners and tubes for plumbing;

- fum tape;

- 12V car compressor;

- two cases from the fire extinguisher;

- pneumatic signal (horn);

- iron plates;

- wires, clamps, hoses, etc.

Tool List:

- welding machine;

- grinder;

- set of wrenches;

- drill;

- taps for threading.

Homemade manufacturing process:

Step one. Receiver assembly

First of all, we will make a receiver, it will accumulate air under a certain pressure to power the sound signal. The author used two cases from a fire extinguisher, since one container is too small. Bleed the gas, unscrew the valve and pour the powder.

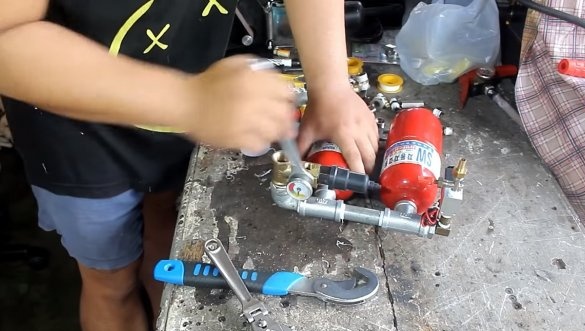

Next, instead of valves, we wrap the tubes and, using the corners, connect the two fire extinguishers into a single tank.

Step Two Equipment

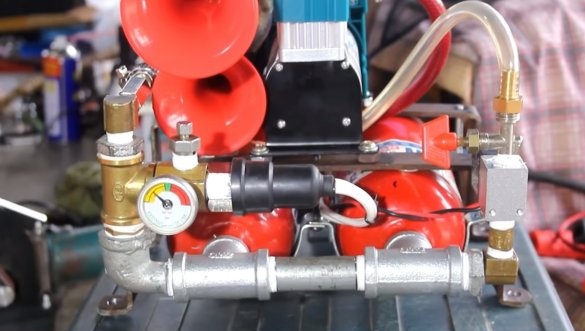

It is necessary to install the necessary equipment on the receiver, for the installation of the manometer, sensor and emergency valve, the author made a “tee” from the valve body from the fire extinguisher. Just drill the required number of holes in the copper case and cut the thread. By the pressure gauge it will be convenient to adjust the signal.

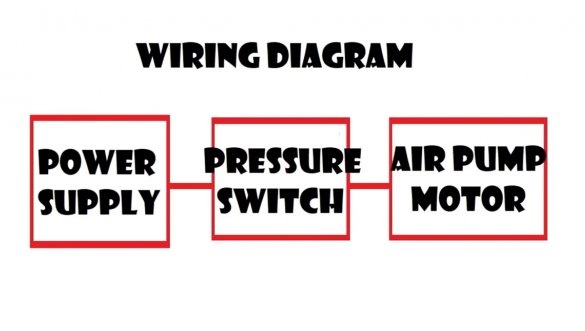

Electronic the sensor is needed in order to turn the compressor on and off, depending on the pressure in the receiver, it has the corresponding adjustment.

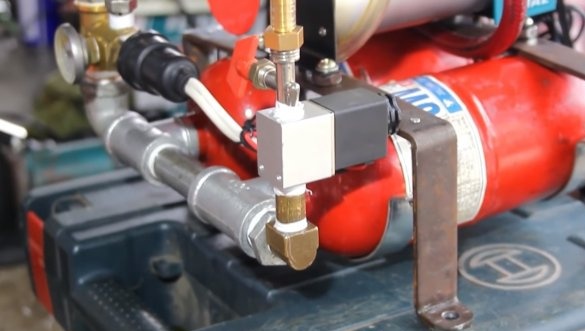

At the other end, at the output of the receiver sets an electric pneumatic valve to 12V and a crane. When turned on from the passenger compartment, the valve opens and releases air from the receiver, which enters the hearth. A crane is needed in order to regulate the volume of air and, as a consequence, the volume of the hearth.

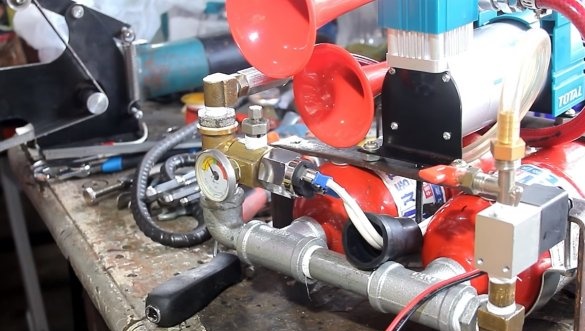

Step Three Assembly

The design can be assembled, for a start we will twist everything together, for this the author made an appropriate bracket from iron plates. We also install our compressor on top and connect the air hose to the receiver inlet. As for the power cable, we connect it to power via an electronic sensor installed on the receiver. We adjust with the sensor the necessary pressure for the hearth to work, it is better to verify this experimentally. Also, you have to configure the desired amount of outgoing air, it is located at the output of the receiver.

Step Four Test

Homemade ready, you can experience. As an experiment, the author installed a signal on a scooter. We start the device, the compressor will need some time to pump air into the receiver.

Well, then you can honk, the homemade turned out quite interesting. The volume of the horn sound was about 128 dB, but the device's power is enough to make the louder horn work.

On this project can be considered successfully completed, I hope you liked the homemade work, and you found useful ideas for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!