I welcome all fans to craft, today we will consider how to make such a useful thing as a bending machine. Homemade will allow you to quickly and confidently bend sheet metal into a corner with an angle of 90 degrees or less. Homemade is easy to manufacture, but requires a lathe, however, you can get out without it. A threaded shaft is responsible for the power part, the machine does not work relatively fast, but on the whole it is enough for the infrequent use of the machine. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- strong threaded rod and nuts;

- sheet metal;

- corner;

- round pipes;

- round timber for turning;

- paint for metal;

- nuts of large diameter (or other parts for guides).

Tool List:

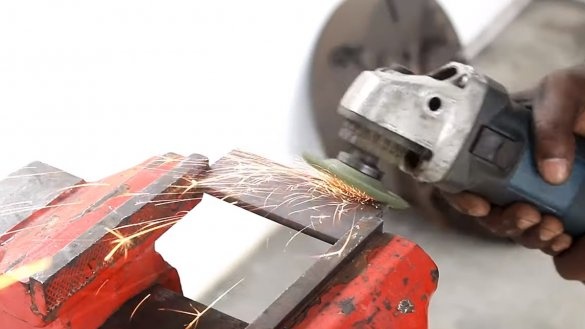

- grinder;

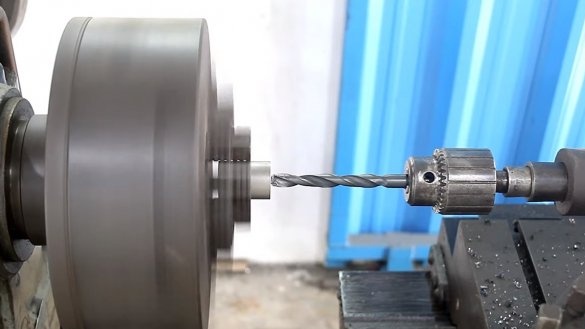

- lathe;

- welding machine;

- drilling machine;

- tape measure, marker;

- a vise.

Homemade manufacturing process:

Step one. Racks

First of all, we need to find a piece of a round pipe, it will need to be cut into two parts of the same length. Pipes are needed for racks, we weld them vertically to the base in the form of an iron plate.

Two nuts are moving along the racks of the author, the inner diameter of which he bored so that they slide through the pipes with a minimum clearance. If there are no such nuts, you can cut pieces of pipes along y to reduce their diameter to the desired one, or vice versa, increase the diameter.

Step Two "Knife"

Iron plates are welded between the two nuts, which results in a platform moving on racks. A “knife” must be welded to that platform, which will press on the sheet metal and bend it.

We cut out the “knife” from iron, or better from a steel plate, we sharpen the end of the product under the wedge and weld to the platform.

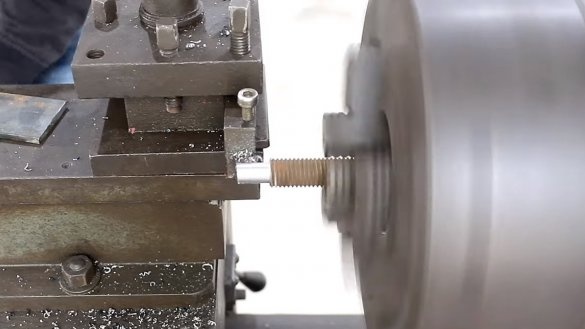

Step Three Shaft

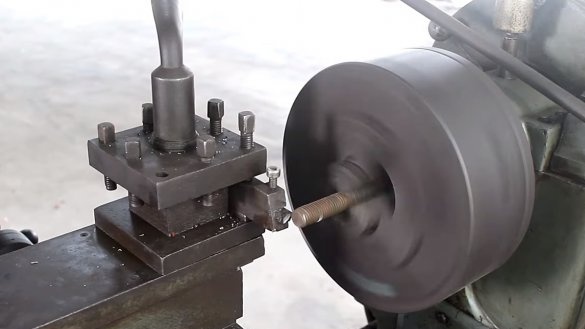

We will prepare a threaded rod, its end must be turned on a lathe. At the end of the shaft, we install an iron plate with a hole and fix the plate by welding a nut to the remaining turned end of the shaft.As a result, the plate mounted on the shaft is welded to the moving platform.

At the top of the racks we also weld a plate with a drilled hole and a welded nut. That's all, now the car is almost ready, the power unit is assembled.

Step Four A pen

We’ll make a handle, the author has machined the necessary one for a handle on a lathe from a round log and welded it to a threaded rod. The handle itself is made of a rod, on the edges of which the author has welded nuts as stops.

Step Five The final

In the end, we need to cut a piece of the corner for emphasis, it is thanks to the corner that the sheet metal will bend at right angles. We weld a corner to the base.

That's all, we paint all the details so that the iron does not rust and the machine can be tested. Before testing, carefully lubricate the threaded rod with grease, it must always be lubricated, then the shaft will last longer and the machine will be easier to operate.

The author easily bends iron plates with a thickness of the order of 2-3 mm, the machine copes with the task. To bend thicker plates, you can strengthen the machine and use a threaded shaft with a special "power" thread.

On this project can be considered successfully completed, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!