From this article we will learn how to cut, bend a glass tube, and also process the end of the tube. Such glass tubes are often used in chemical laboratories and the skills to work with them will not interfere with senior pupils and students. But not only him, using such techniques, it is possible to process not only tubes, but also sheet glass, for decorative or other purposes.

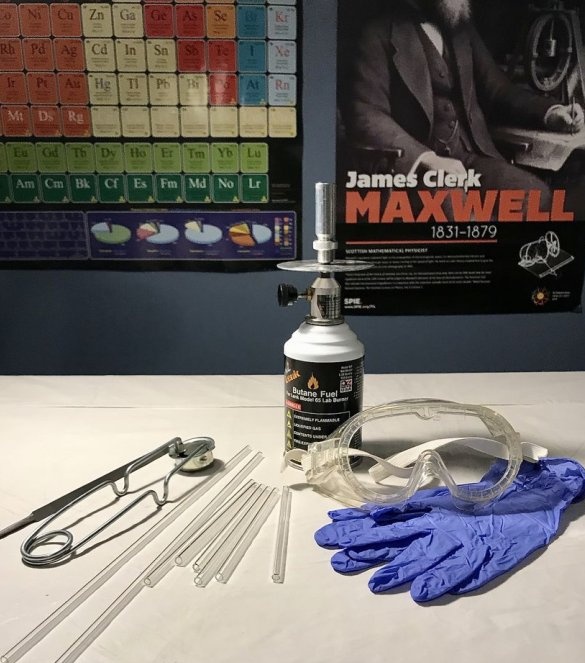

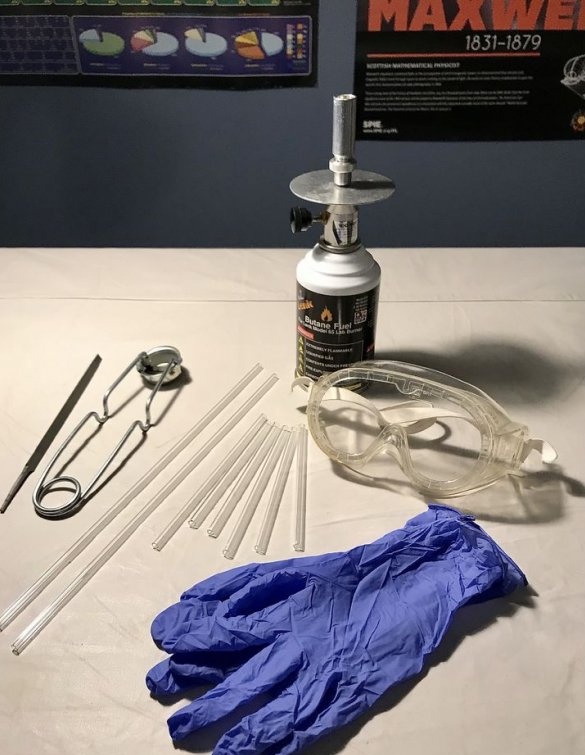

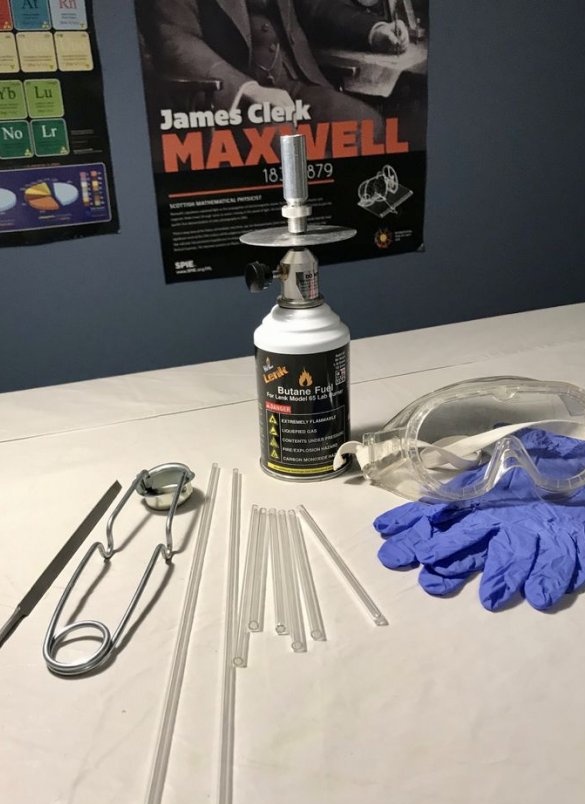

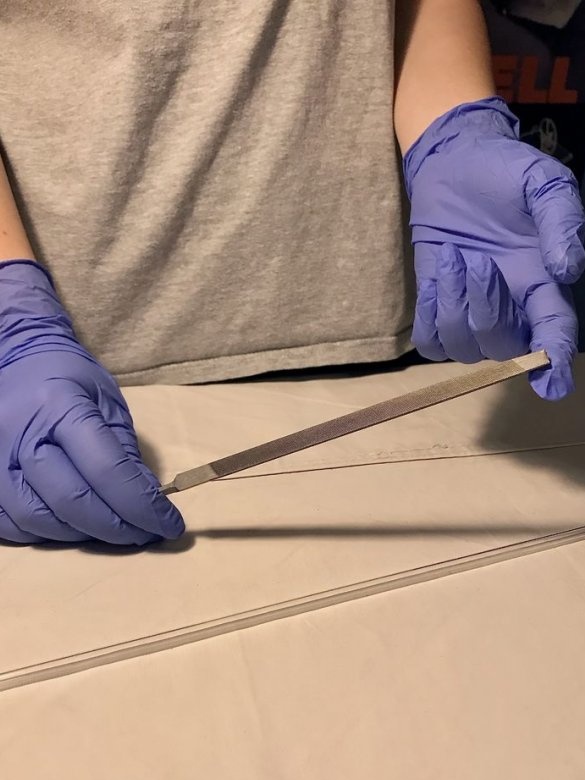

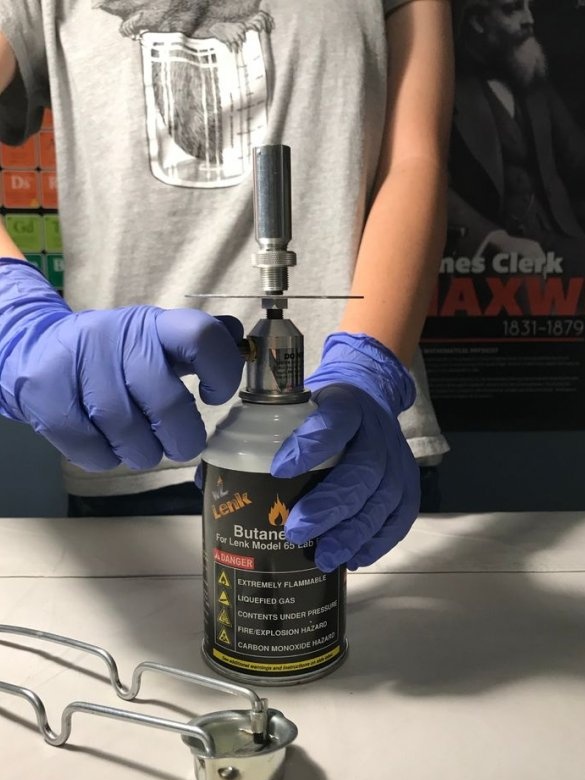

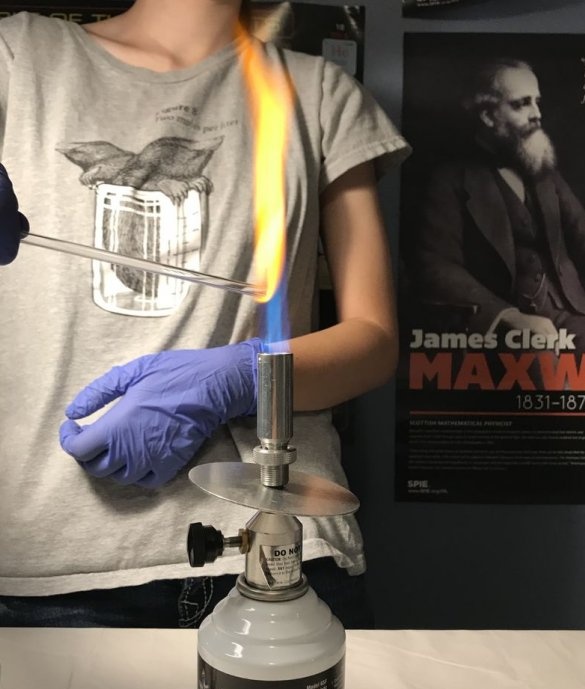

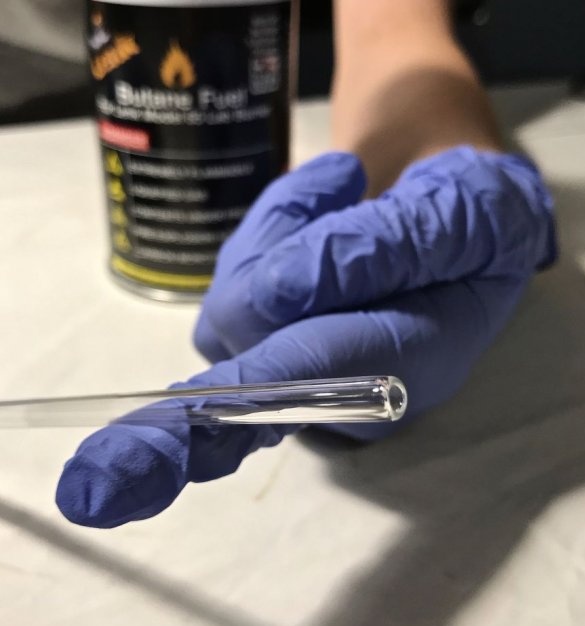

For work you will need the following items: glass tubes, a file for cutting glass, a butane burner, gloves, safety glasses.

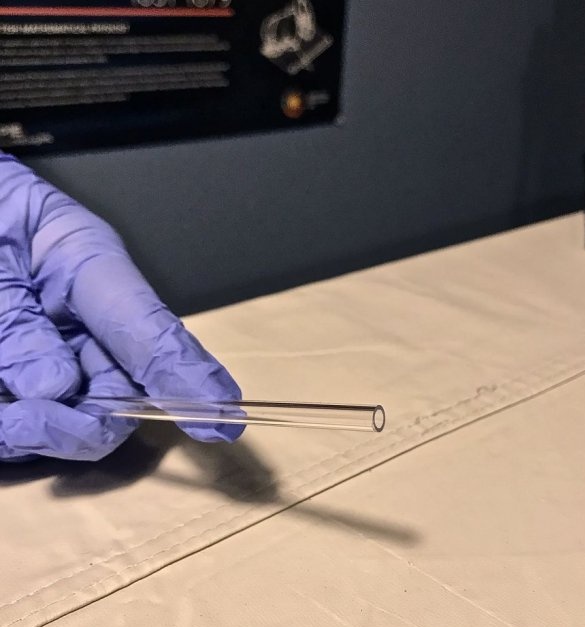

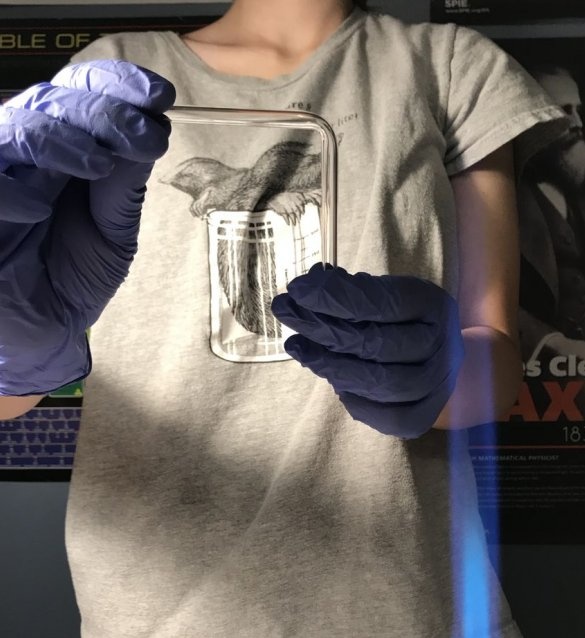

A standard borosilicate glass tube is pretty cheap. It is advisable to have several handsets when learning. Smaller pipes will be easier to work with.

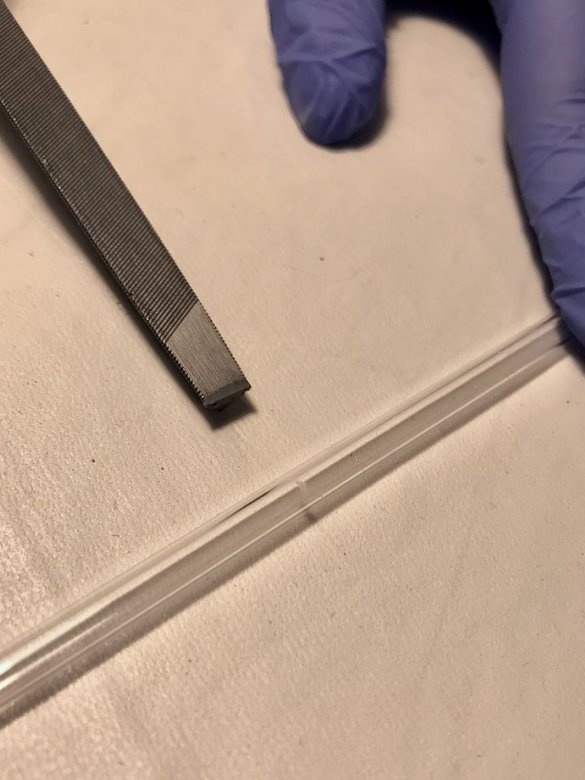

The file, for cutting glass, has a triangular shape, and is used to cut grooves on glass tubes.

Do not try to use an alcohol burner instead of a butane. Alcohol burners and many similar devices do not give a temperature sufficient to work with glass.

Safety precautions.

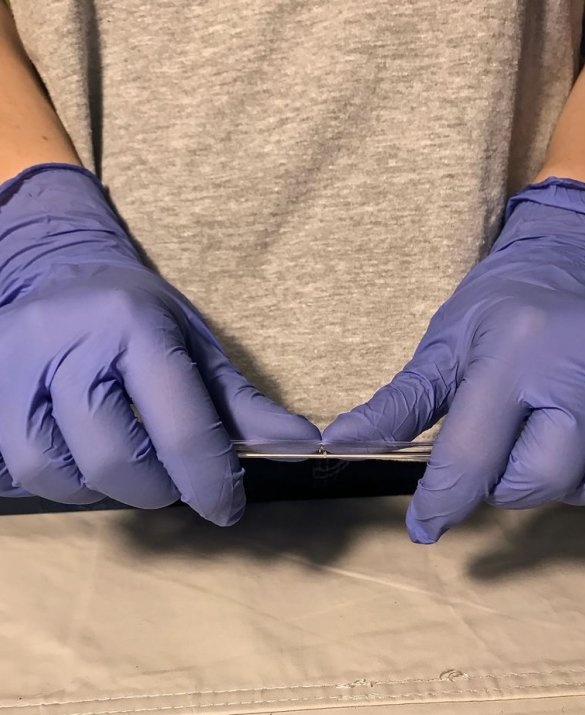

Before you start cutting, bending, or polishing glass, wear laboratory gloves and safety glasses.

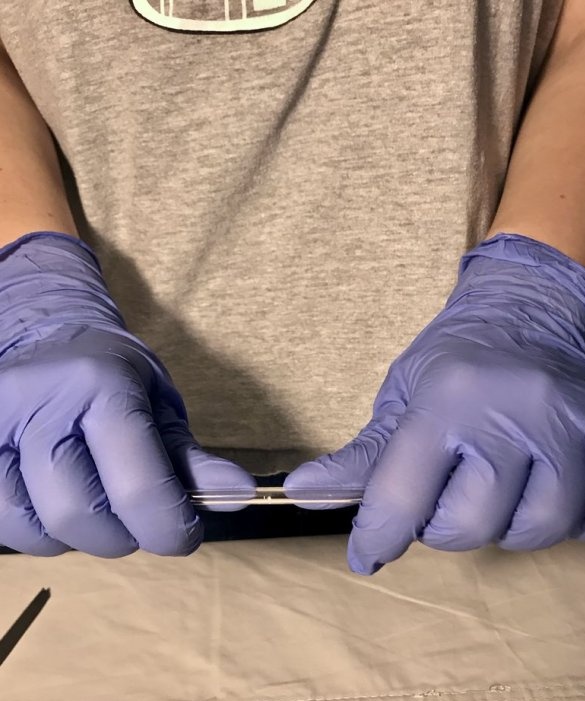

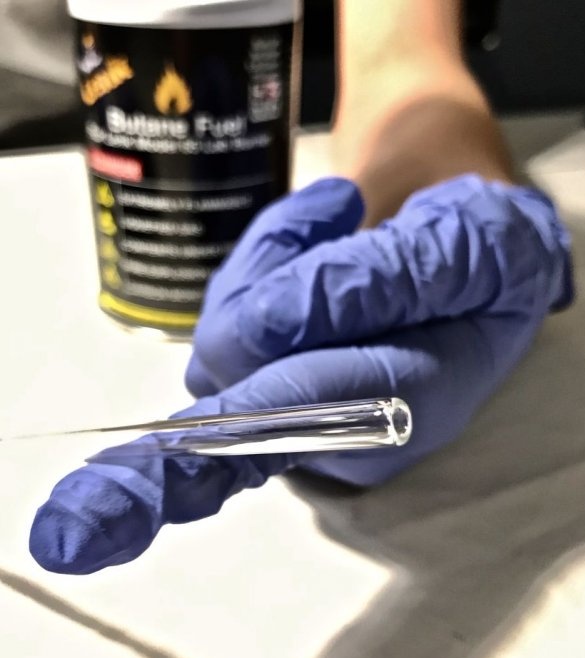

To cut glass tubes, you need to file a notch with a file. Attach the file at an angle to the tube and pull it towards you. Then break the tube at the incision site.

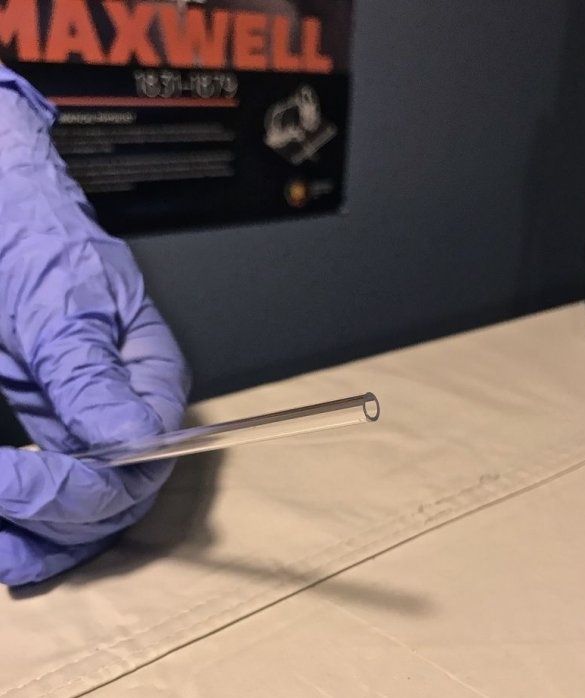

Now there are two tubes, their edges are very sharp. For safety, the edges must be smoothed.

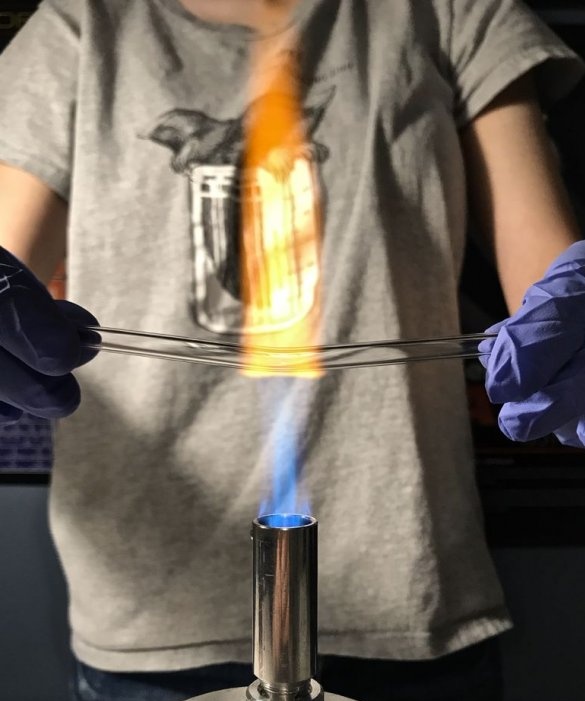

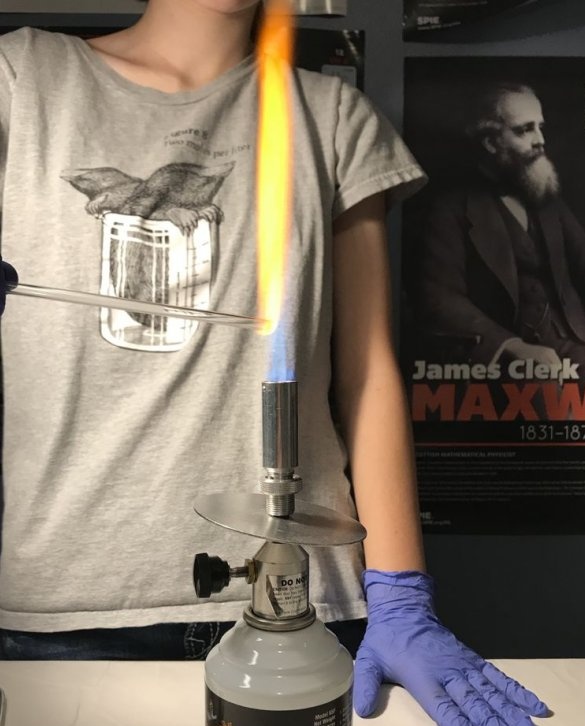

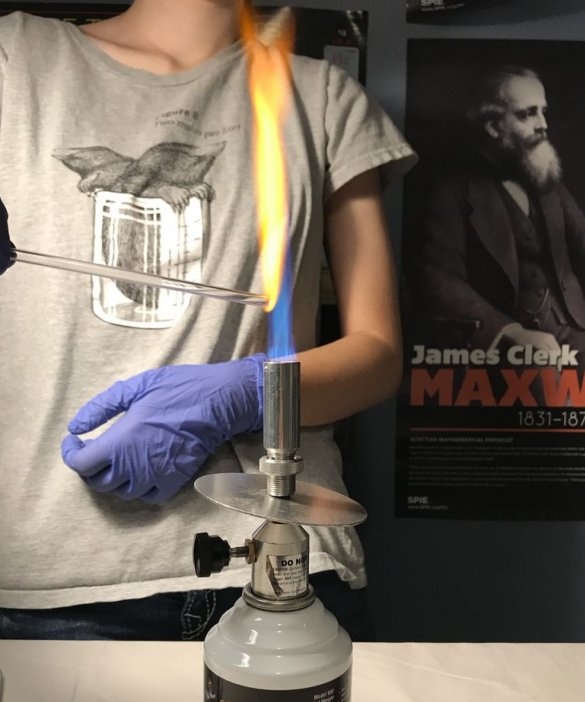

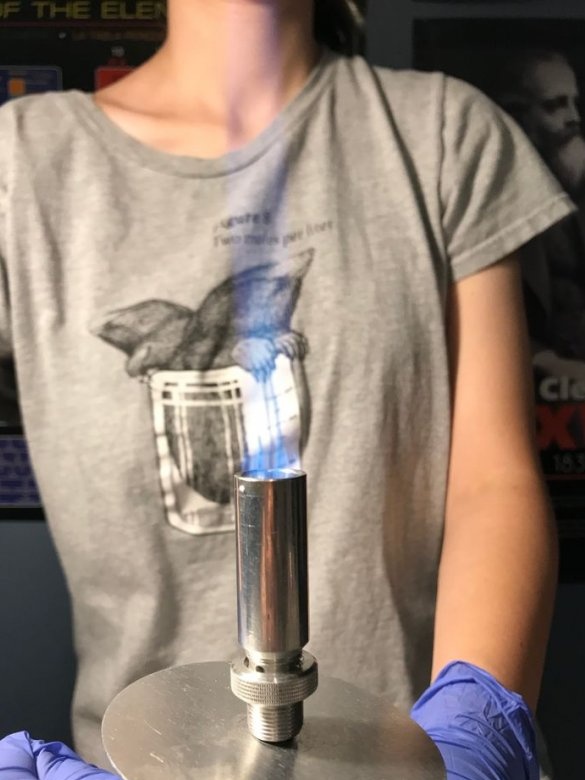

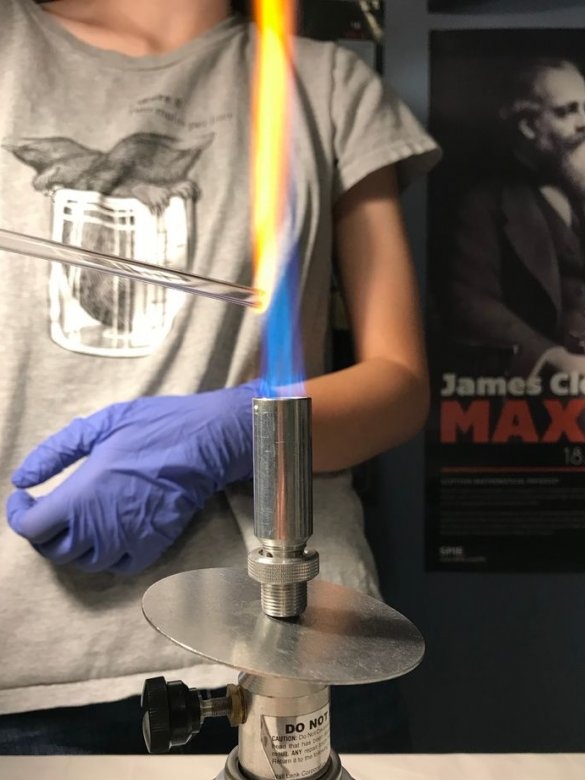

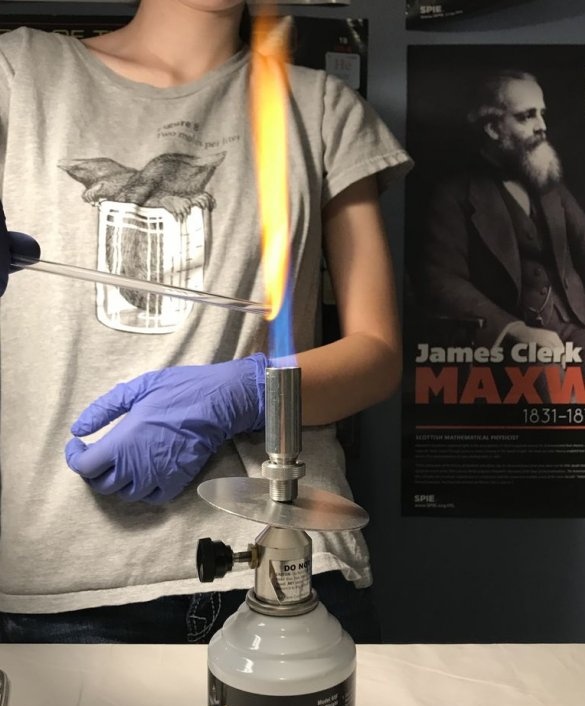

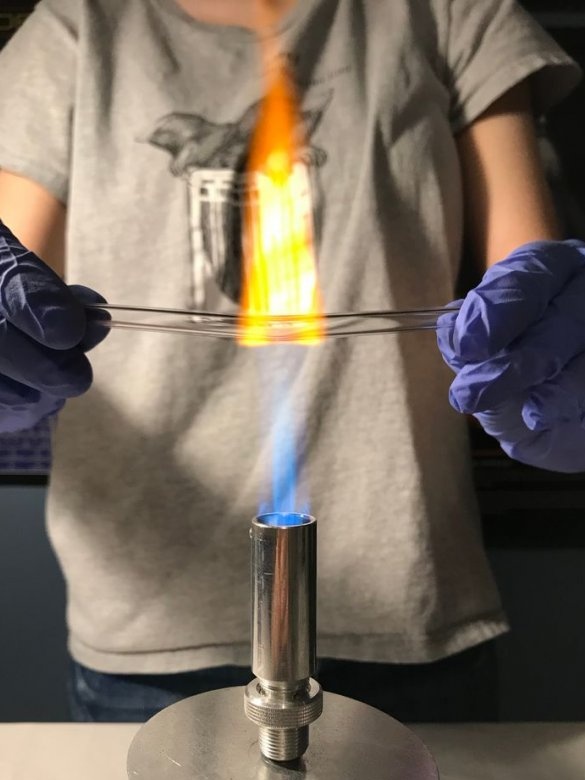

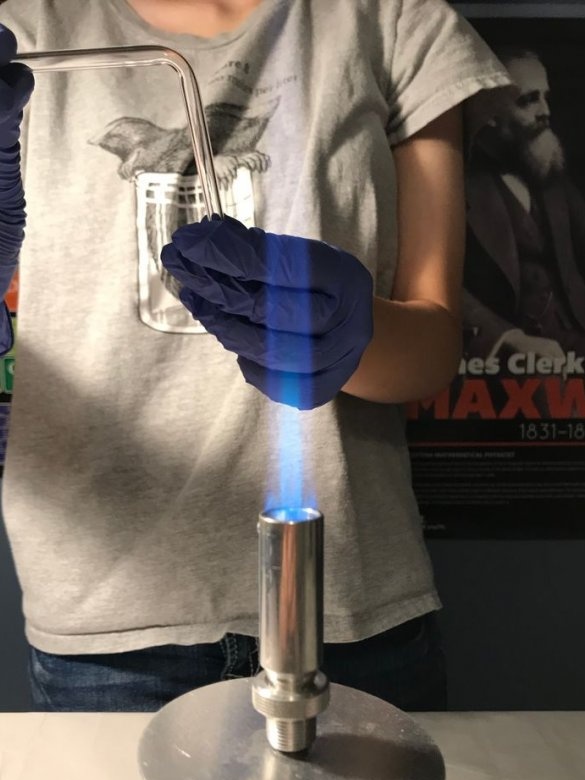

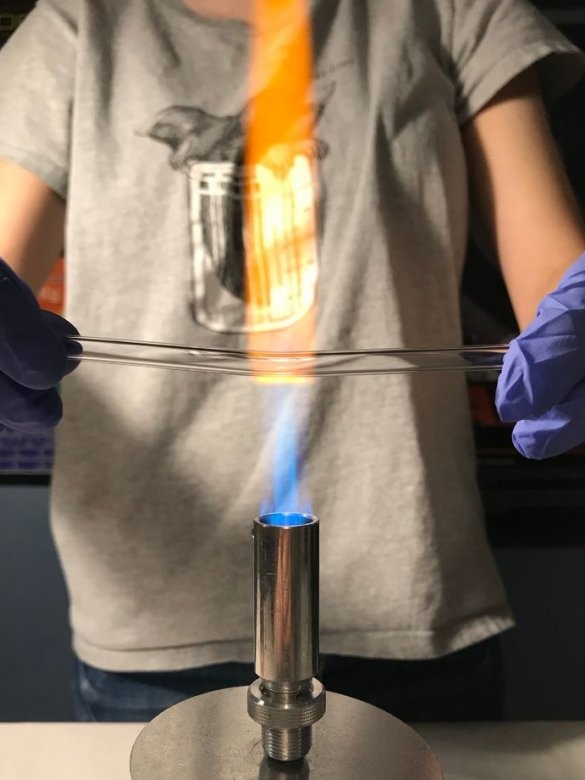

Turn on the butane burner. Unscrew the flame so that it becomes large enough so that you see two “cones”. The outer cone will be a weaker blue and the inner cone more distinct. It is important that the flame is strong enough. Put the glass tube in the flame. Hold the glass tube in a flame, tilting it slightly down so that the edge of the tube is directly on the outermost edge of the center cone. The flames around the glass should be bright orange. It may take some time to position it correctly, but keep moving it until you see this bright orange flame.

After the glass tube is installed correctly, rotate it slowly, back and forth, so that the end heats up completely. Watch carefully when it starts to melt. Continue to rotate the tube to maintain its shape. The edges will become smooth and rounded.

Now that the edges have been polished with fire, remove the tubes from the flame. Continue to slowly rotate it for several seconds, so that it cools without changing its shape. Then let it cool completely.

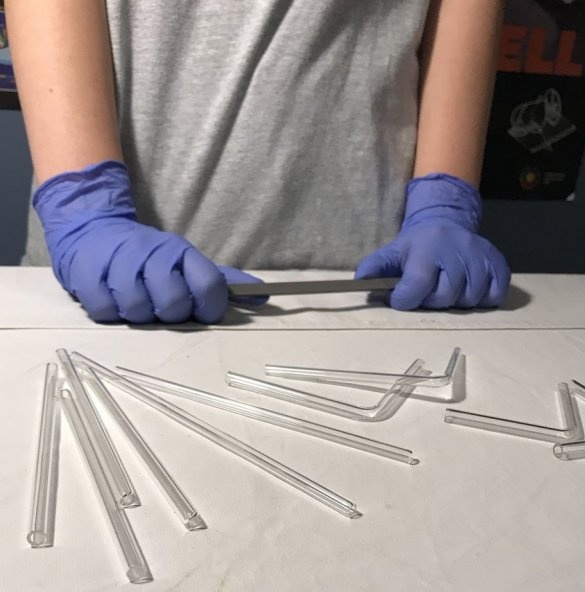

Now consider how to bend the tube.

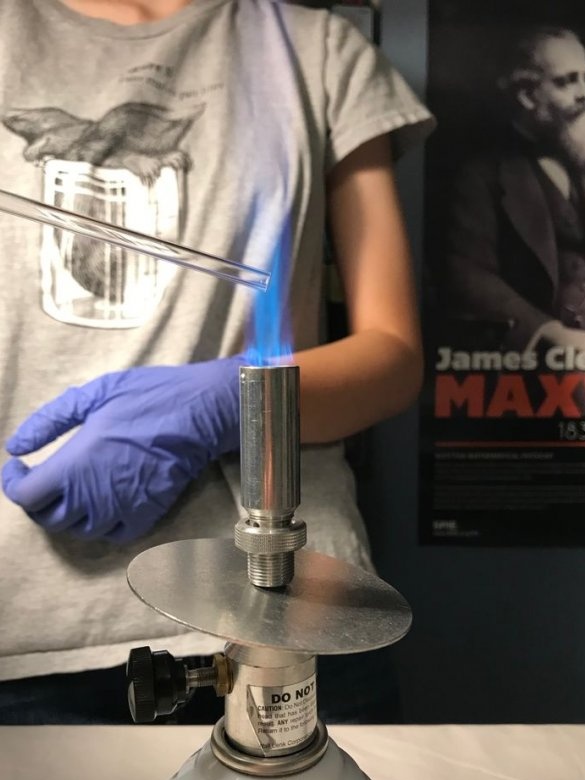

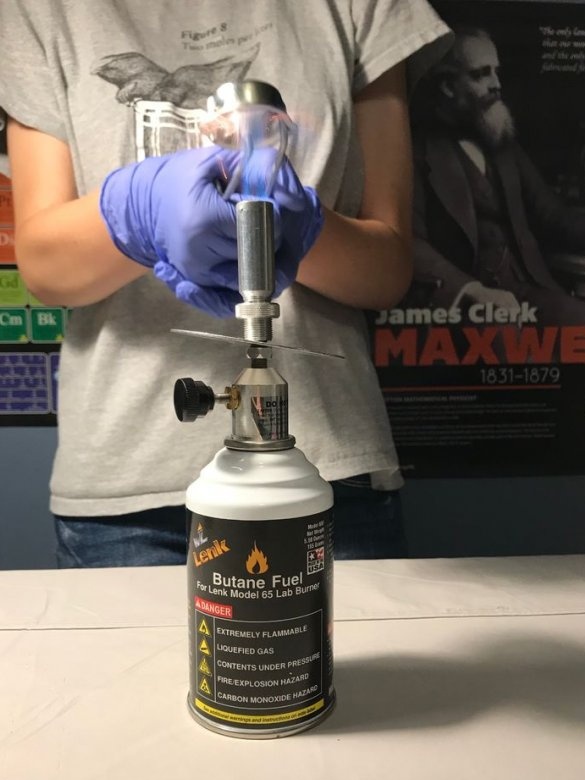

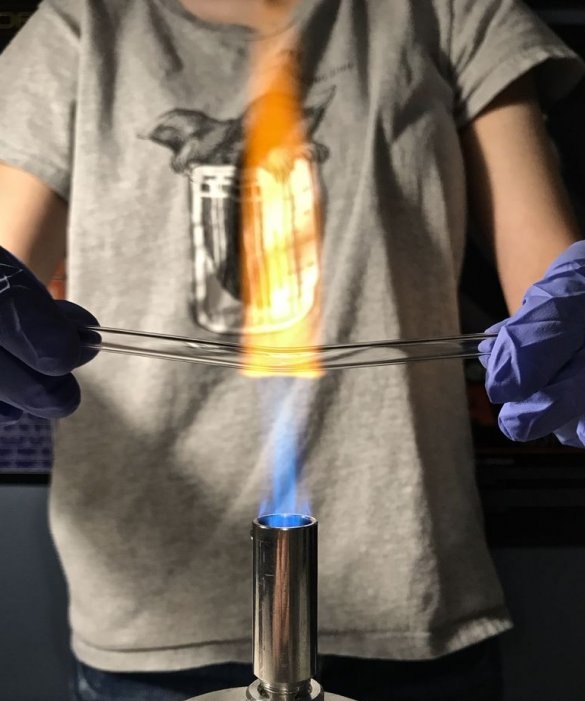

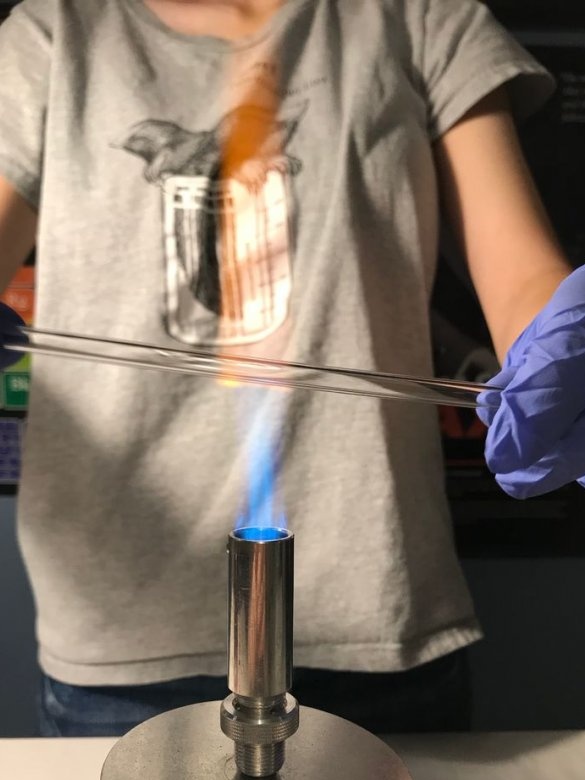

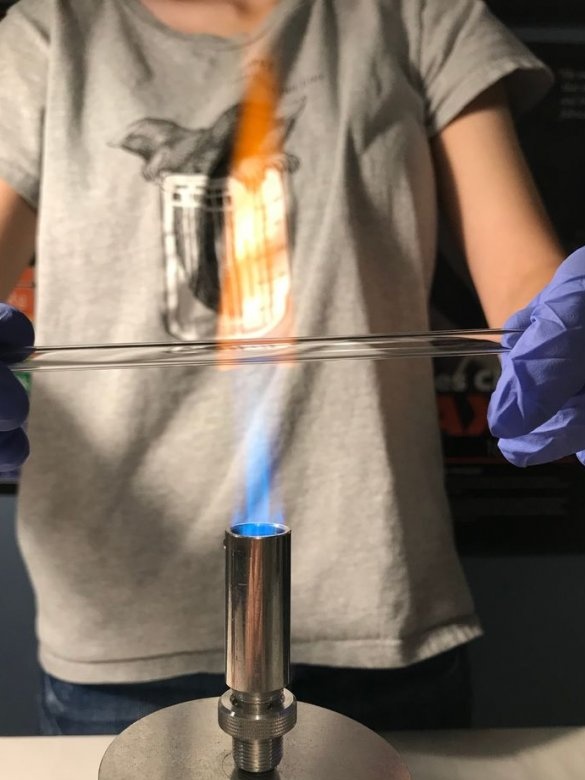

Light the burner and adjust the flame, as in the previous example. Start heating the tube by moving it back and forth through the end of the flame. The flame will be a faint orange, which will intensify when the glass becomes hot. Heat the glass about 2.5 cm on either side of the point you want to bend. Heat the center longer than the edges.

When the glass in the center begins to melt, you will feel the tension in the glass ease and you will see how it begins to bend. Continue to evenly move it through the flame and carefully, slowly, bend at an angle of 90 degrees. If the tube becomes too soft and bends too quickly, remove it from the heat and continue to bend slowly, and then warm it up again.

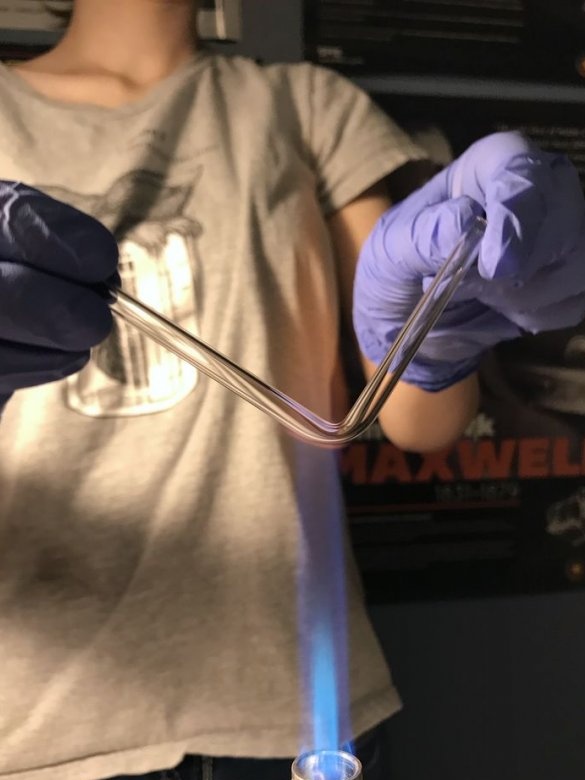

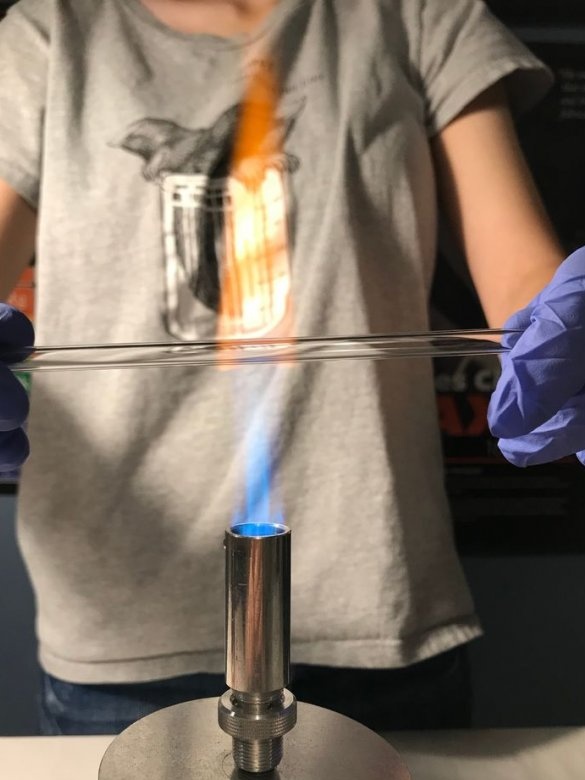

After the glass is bent at an angle of 90 degrees, immediately remove it from the flame and keep it in the air so that it cools for 30-60 seconds. Then you need to anneal the glass, warming the knee of the glass tube through the flame of the burner for some time. At this point, the glass should not become so hot as to become soft again. This technique will remove stress and the glass will not burst when cooled.

After annealing, remove the glass tube from the heat and let it cool completely.

In this way, you can give the tube another shape, a circle, a spiral, various angles, etc.

That's all. These are the basic techniques for working with glass tubes. Perhaps the first time you will not succeed as you need, but, as Albert Einstein said, “You should learn the rules of the game. And then you will play better than anyone else.”