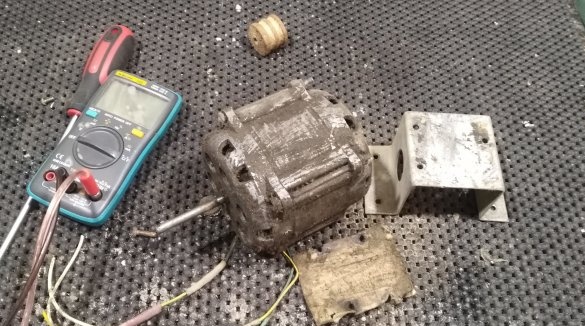

Hello! Today I will show how I made a mini lathe from everything that was in the garage. The machine was made suddenly and not planned, as an old 60 W engine was found. Then I had to clean it and check for working and starting windings.

When everything worked, it was possible to make pulleys for the drive through a rubber seal that served as a pasik in homemade.

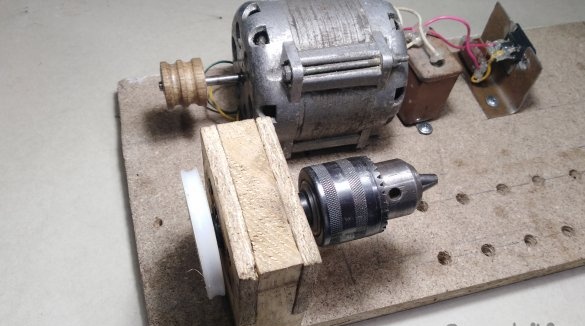

These pulleys are: Master and slave, slowdown somewhere around 2.3 times.

Now I had to find a cartridge, I have 1.5-13 mm, on the finished shaft. Next, I found two bearings that dangled a little, but did the punching in the places of the bearings, everything landed clearly and reliably, I guess.

Some bushings and holders had to be made of wood for bearings.

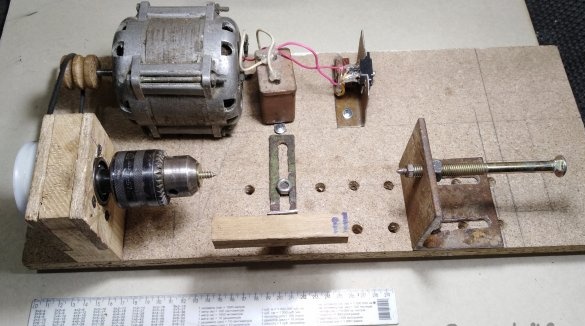

That's what happened

Materials: Bar (spruce) OSB 8 mm

Next, I had to press the bearings into place and bore the dies on their main panel in which the axis will stand exactly in the center and exactly at 90 degrees. Also, if the angle is different, you can substitute pieces of plastic veneer or something else.

In the large pulley, I had to make a hole slightly smaller than the diameter of the shaft. Well, I’ll adapt all this: I installed the engine and the front headstock on a 16 mm thick fiberboard piece.

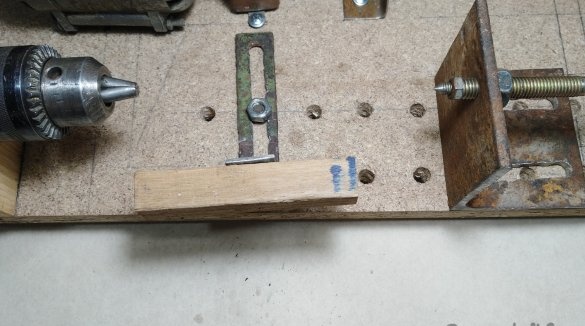

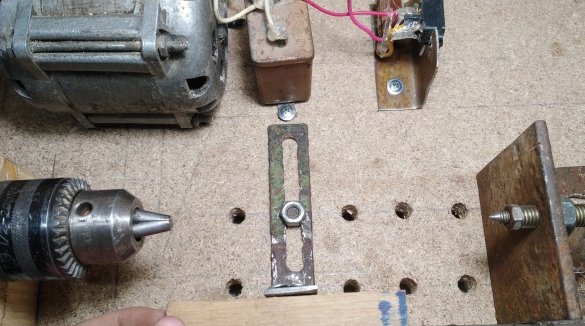

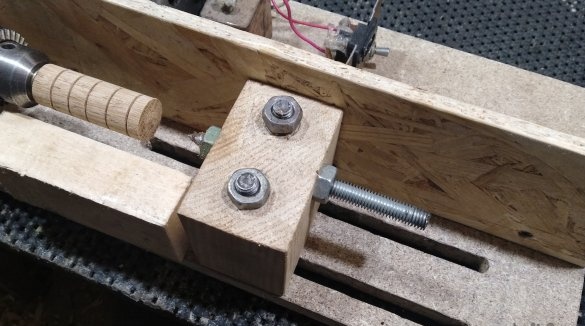

Now I had to make a tailstock, I have a 5 mm thick corner and an M12 bolt. The tailstock and the handmaker moves along the previously made holes.

The last step was the handcuff and strips 2 mm thick, bent at 90 degrees and a small bar 10 cm long was screwed. Everything is screwed with m8 bolts, previously into the holes made.

That's ready machine

Here's what was done in an hour from beech with the help of this machine and the usual semicircular chisel.

After all robots I modified the machine a bit, as chips in the engine were forgotten and the tailstock was not so convenient.

Thanks for watching, you can also watch the video, but that video is without modifications.