Perhaps some of you have already made parabolic mirrors from old satellite dishes. But they are quite heavy, and have a number of disadvantages.

In this article, the author of the YouTube channel "NightHawkInLight" will tell you about the technology of creating a light and cheap 28-inch parabolic mirror. It can be used for a number of different processes from heating media to cooking. It can even become part of a telescope.

Homemade is quite simple for self-manufacture, and the cost of materials is quite low.

Materials

—

- Construction foam

- fiberglass fabric

- nipple

- Two-component epoxy resin

- Sheet polyurethane foam

- Plastic tape

- Pine boards, steel corners

- Aerosol contact adhesive

- Silicone sealant.

Instruments, used by the author.

- Cutting disc

— Bicycle pump

—

—

— .

Manufacturing process.

The creation of such mirrors involves the use of compressed air, which helps to form a parabolic shape from a sheet of aluminized film "Mylar". Mylar is usually sold in the form of rescue blankets. Mylar is mounted on a flat, airtight surface. After that, increased pressure is created under it, as a result of which it is inflated like a giant bubble.

The first thing the author begins to work on is the surface itself, on which the material coated with aluminum will be inflated. The author decides to test for this purpose a half-inch sheet of polyvinyl chloride fiber. It is airtight and perfectly even. What you need.

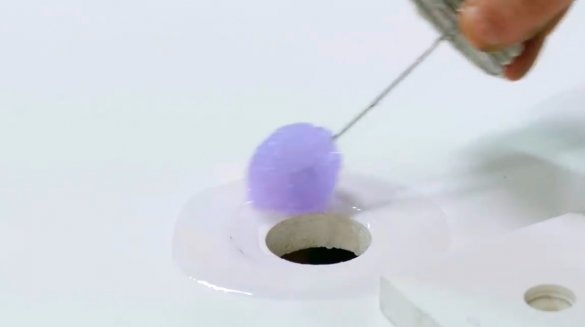

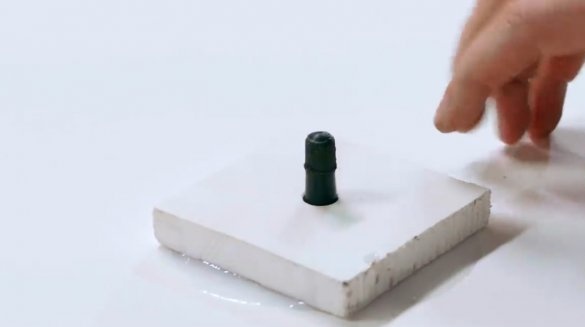

In the center of the sheet, the author makes a hole for air supply. To do this, you must first mount the nipple from the bicycle chamber into a small piece of PVC sheet.

A fairly large hole will be clearly seen in the center, the edges of which are processed with PVC glue. A prepared unit with an integrated valve sits on it, with the valve leg up.

If you turn the sheet over, the back, the author’s idea becomes clear - the valve is buried here in the surface.

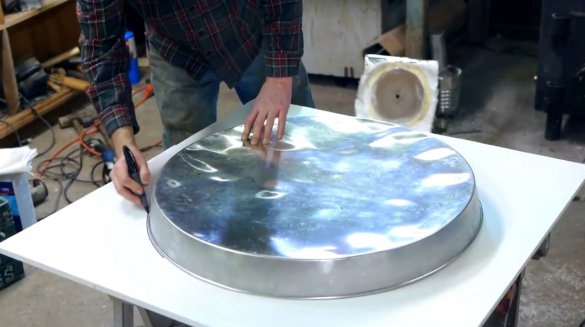

The next step, the author sketches the contours of the circle of the diameter, which should be a mirror. This can be done using a large compass, or a suitable shape.

On the outer circumference of the circle, he processes the surface with sandpaper. It is along this contour that glue will be applied to fix the mylar, and seal the desired area.

As mentioned earlier, Mylar is sold in the form of a life-saving blanket and is packed several times folded, which causes many folds to appear on its surface.

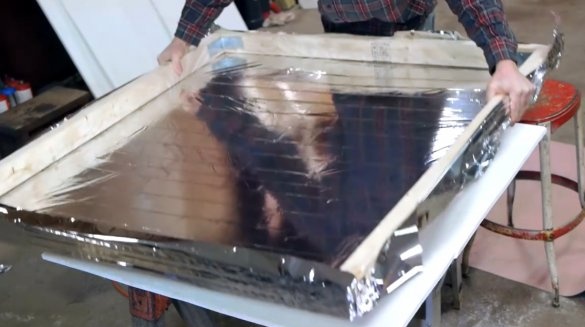

Before forming a mirror prototype from it, it must be leveled. The author makes specially for this a wooden frame, slightly larger than the PVC sheet itself. And stretches an aluminum-coated film on it.

The easiest way to connect Mylar and a wooden frame on a temporary basis is contact adhesive in the form of a spray. At a time, the author processes only one of them, the upper surface of the frame, fastens the Mylar without folds, then flips the frame with the opposite edge, again treats it with glue and tightens the film to align all the folds. In the same way he fastens the other sides.

Excess film is removed.

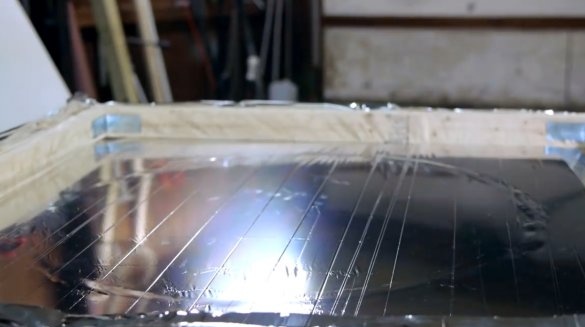

From past experiments, the author was convinced that Mylar is best glued with PVC to epoxy. He covers it with the circumference of a circle and lowers the frame with the canvas from above. After that, he immediately presses the Mylar in a circle so that an isolated space forms in the center. The epoxy must dry properly.

To pump air into it, an ordinary bicycle pump is used. It is difficult to determine to what extent Mylar can be inflated before it breaks through. But fortunately, it almost immediately took the form of a parabola.

To fix the desired shape, the author, at the first attempt, covers the Mylar with ordinary construction foam.

But the result was very sad. It is good that the base can be easily cleaned and reused.

In the second attempt, the author covers the parabola with a two-component epoxy resin.

And then a layer of fiberglass is laid on top.

During the time while the fiberglass hardens, you can slightly pump up the “bubble”. Meanwhile, he imposes two more layers of fiberglass.

To speed up curing, and to avoid deformation of the parabola, the author warms up the mirror with a hairdryer.

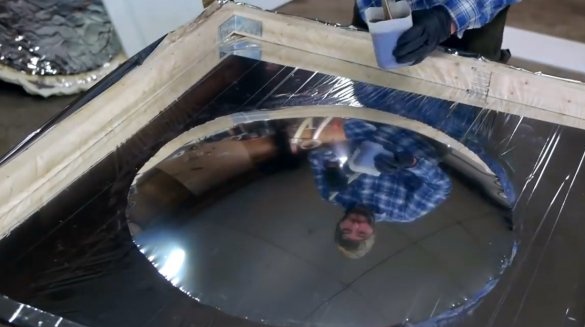

In order not to damage the mirror, the author cuts off the mirror from the base with a grinder.

And here he is the result! The reflectivity of such a mirror is pretty good.

The only thing is that fiberglass is somewhat more flexible than we would like. Due to this, the parabolic shape of the mirror itself is somewhat disturbed.

The author decides to fix the form with a hoop. For this purpose, the plastic side for the garden turns out to be very opportune. The author folds it into a ring and fastens it with bolts and nuts.

The hoop is placed on top of the mirror, which is pressed firmly by the load so that its edges straighten out a bit and the surface takes on the required shape.

The mirror is smeared around the circumference with silicone sealant, and left to dry.

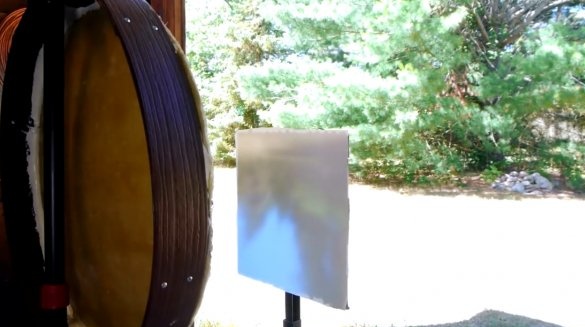

Now check the result. Given the cost of materials, the result is pretty good. A smoother surface could be achieved if the Mylar could be inflated a little bit more.

Here is a picture formed by a mirror on a sheet of cardboard.

And with such incredible ease even a thick log is ignited.

Now the technology has been mastered, and you can improve the design of the mirror, change the focal length to fit your needs. As you already understood, with the help of a group of such mirrors you can form a cheap heating installation.

In addition, you can experiment with the shape of the mirror, making it in the form of a half pipe. Then it will turn out to use a longitudinal receiver of sunlight in the form of a pipe with a coolant located along the entire focus.

Thanks to the author for a simple but very interesting technology for creating parabolic mirrors!

All good mood, good luck, and interesting ideas!

Author video can be found here.