Trouble happened, the Check Engine light on car, a scan by the scanner showed error 0505, air leaks, respectively, incorrect measurement of the amount of air by the electronics and improper mixture formation. In my car, this was expressed in unstable idling and sometimes freezing of revolutions, the engine did not reset to idle when refueling.

Checking by light spot spraying with a quick start to the intake manifold at idle showed that somewhere there is a hole, the speed increased, but the leakage could not be visually determined. Compressor injection of air under pressure into the intake manifold also showed a leak and narrowed the space a bit, but again, no specific location was found. I remembered about the smoke generator and fired up to do it yourself, which I bring to your attention.

The Internet is full of all kinds of examples, but they are mainly based on candles from diesel engines, nichrome wires and even cigarettes. Kapets. None of this was at hand, but a broken 40-watt Chinese soldering iron was lying around. The sting fell off at the point of attachment to the plastic handle, and besides, he did not want to regulate the temperature of the sting, he was overheating. It’s good that he didn’t throw it away, we only need a ceramic heating element and a power cord from it. There were no metal tubes either, I found plastic ones from a water filter, for the first time it will do.

For the manufacture I used:

1. A jar of baby food with a metal lockable lid,

2. A metal grid for washing dishes,

3. The heating element from the soldering iron,

4. A power cord with a plug from the same soldering iron,

5. A plastic tube, later replaced by 2 metal ones,

6. Cold welding.

By the way, I found the same heating element separately on Aliexpress, can someone come in handy.

To begin with, we mark the places of the holes, central for the rod, side for the tubes, through one we will supply air, the other end will be connected to the intake manifold.

We drill 3 holes for the diameter of the tubes and the rod from the soldering iron. It should be something like this.

Fitting a heating element.

... and pipes.

And all together in the bank.

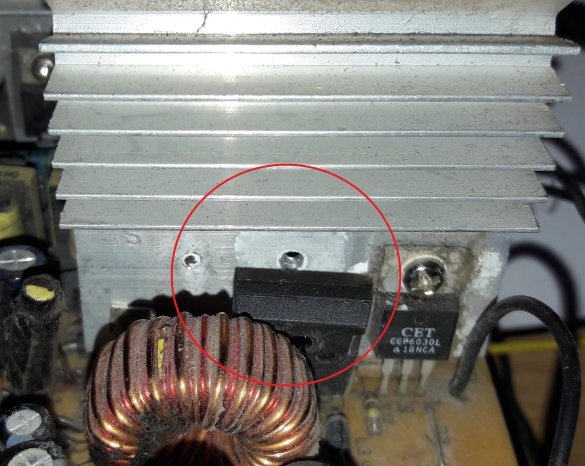

The next stage, we fix the heating element, for this we wrap the very tip, which will be mounted on the cover with non-combustible material, I used a gasket from a powerful diode assembly from a broken computer power supply.

I wrapped the tip of the rod with this gasket and secured it with electrical tape.

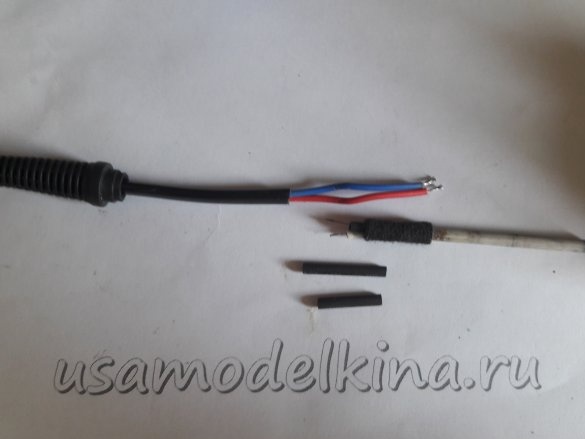

The next step is to solder the network cable to the element.

To make contacts, he used soldering acid.

Class, you can solder the wires. First we put on a cambric wire, solder it.

We put on shrink cambric, heat it.

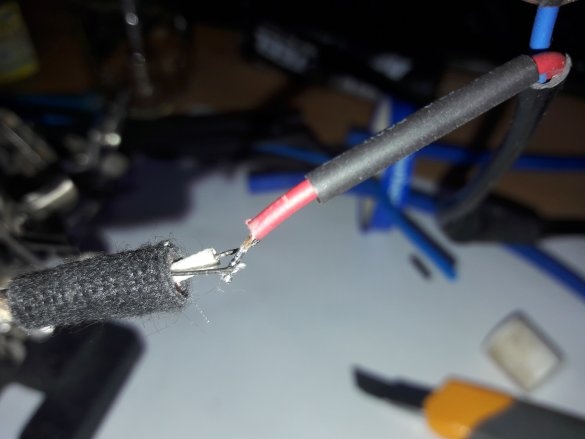

Same thing with the second contact.

We prepare for fastening in the lid of the can using cold welding.

Before using cold welding, it is advisable to soap your hands and let the soap dry a little, then the cold welding residues that stick to your hands can easily be washed off.

We put a metal mesh in the jar, it is better to use a rigid one. There is still a soft one on sale, it burned out in my place of contact with the rod.

After the hardening of cold welding, we try to work. In work I tried different liquids. Glycerin smokes best of all. The pharmacy sells in jars of 25 ml for 25 rubles, I needed 3.

I noticed that the heating rod does not heat up along the entire length, but only in the middle. And if the liquid comes into contact with this place, the smoke becomes more.

After many attempts with different fluids that I found at home, plastic pipes started to melt, by then I found metal pipes. The tubes from the telescopic antenna from the old receiver came up well.

Smoke begins to go about 10 seconds after switching on and its intensity does not decrease during purging.

When checking on a car, I found 3 places. The rubber tubes in a fabric braid cracked, although visually, to the touch and bending were in perfect condition, I would not have found it without a smoke generator.

Unfortunately, it was not possible to show other places, it is difficult to repair the car and remove at the same time. In conclusion, I’ll add that it’s probably not possible to use such a smoke generator in everyday car repair work, but it’s quite possible to fix your car.

Worked for 15 minutes (the glycerin in the jar is boiling, naturally the jar is heated) with short breaks to eliminate malfunctions. The metal tubes at the junctions with the glue gave a small leak, perhaps it was necessary to solder these places. But in general, I am pleased with the result. The error disappeared, the idle returned to normal, and freezes at higher speeds disappeared. And it felt like the car began to respond better to the brake pedal.

I shot some of the experiments on video: