Surely many of you are faced with the problem of cleaning small parts. Often this can be solved by chemical means, or manually. However, there is one old way.

In this article, Alexander, the author of YouTube channel Alexander Polulyakh, will tell you how he made a simple desktop vibrating machine.

This homemade product is very easy to manufacture and can be repeated in a few minutes.

Materials

—

- Power Supply

- 6 liter plastic bottle

- M12 bolt

- Silicate brick

- sand

- Screws, dowel.

Instruments, used by the author.

—

—

-, metal drills

- Ceramic drill

—

- Vise drilling machine

- Joiner's knife, hammer

- Hacksaw for metal, scissors.

Manufacturing process.

So, for starters, Alexander cuts the bottle in half.

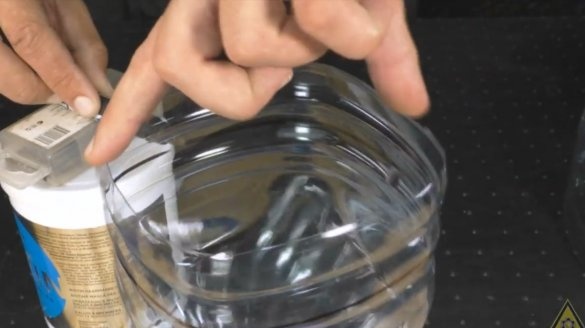

Then you need to attach such a corner to its bottom.

To do this, he puts a corner to the bottom, and melts four holes in the bottle with a nail.

With the help of metal screws it fixes a corner.

Then screw the engine to the corner. Engines can be used almost any, the main thing is that they have enough power, and the rotor was mounted on bearings, otherwise the motor will quickly fail.

Now, in such a simple way, marks the cut line on the second part of the bottle, and cuts it off with scissors.

Using a knife, cuts four sections at the top of the bottle. The resulting elements are cut into three parts.

Next, you need to bend the resulting petals just below the middle.

A hole for fixing is burned in the center of the cork.

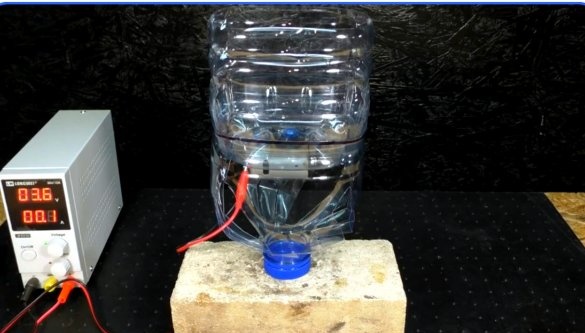

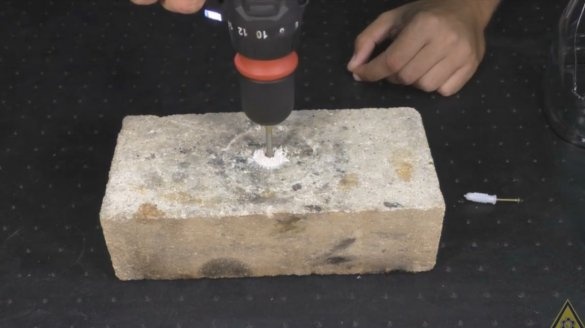

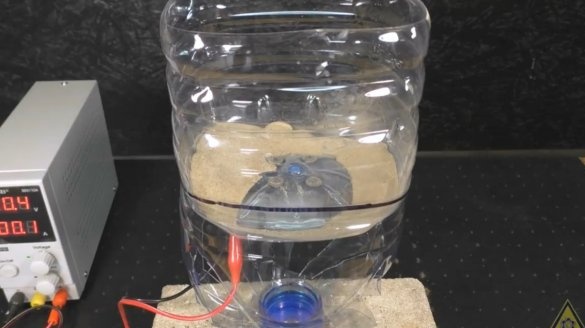

In an ordinary silicate brick, a hole is drilled, the dowel is clogged, and the cork is mounted upside down.

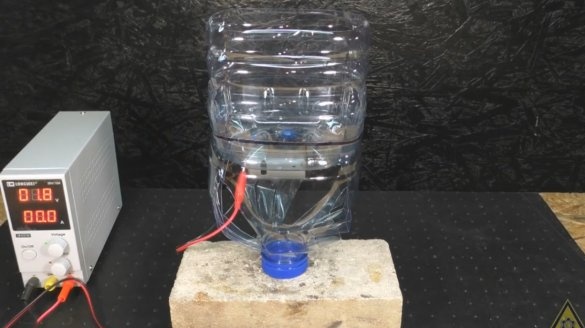

Screws the first section into the cork, and on top puts the container with the engine. It turns out a very movable structure, and this is required for such installations.

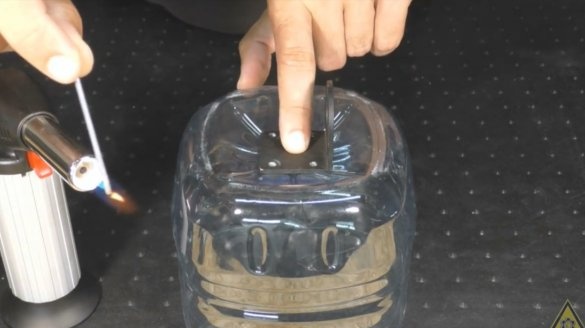

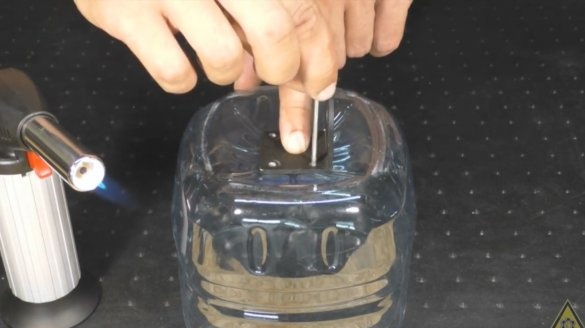

The last thing to do is to make an eccentric from a bolt. First, the hole for the motor shaft is drilled. It must be done with an offset from the center.

Part of the thread is cut, and several faces.

The author turns out to be the simplest eccentric.

Now it needs to be pressed onto the motor shaft.

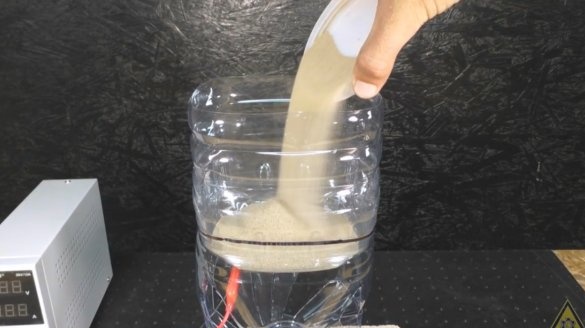

The engine is connected to a laboratory power supply, sand is poured into the tank, and the installation is ready!

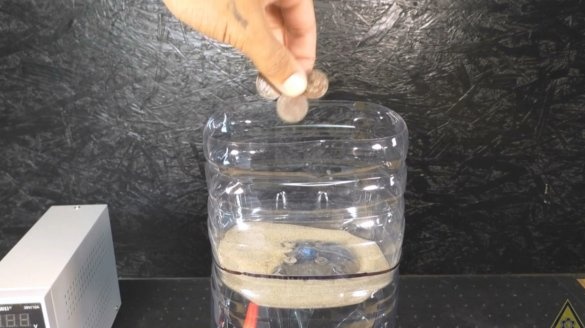

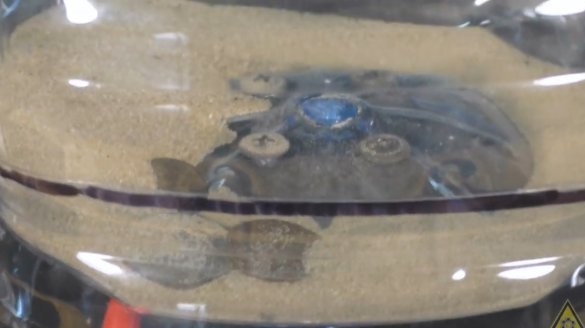

Alexander will use some very dirty coins as a test. Puts them in a container, and turns on the power. Of course, instead of a laboratory unit, you can use the usual one.

This process is very slow, and cleaning may take several hours. Under the influence of vibration, sand and coins are constantly in motion.

It turned out that two coins are quite old, and one is modern. In this way, you can clean not only coins, small iron parts, but also shrink the epoxy or gypsum for small homemade products.

Thanks to the author for a simple but useful vibrating machine for the workshop and home!

All good mood, good luck, and interesting ideas!

Author video can be found here.