Greetings to all connoisseurs of good knives and lovers of working with metal. Today we will look at how to make a quality kitchen knife in the Japanese spirit. Unique feature homemade we can assume that the blade is made of steel Buderus nitro-B. Such steel has a number of features due to the fact that the metal is enriched with nitrogen. Thanks to this and other additives, the steel does not rust, is not afraid of many acids, and is also able to achieve hardness during hardening in the region of 60HRC. An interesting fact is that it is necessary to harden steel with liquid nitrogen, the hardening temperature is -80 ° C.

The knife handle is also not unusual, it is made of stabilized wood, which makes the tree immune to water and dirt. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- steel plate Buderus nitro-B;

- whetstone (for the handle);

- materials for insertion into the handle;

- oil for wood;

- epoxy adhesive.

Tool List:

- belt grinding machine;

- tape cutting machine;

- drill;

- sandpaper;

- oven, foil, borax, liquid nitrogen (for hardening);

- polishing machine;

- a vacuum chamber to normalize wood;

- clamps;

- vise;

- hammer, etc.

The process of making a knife:

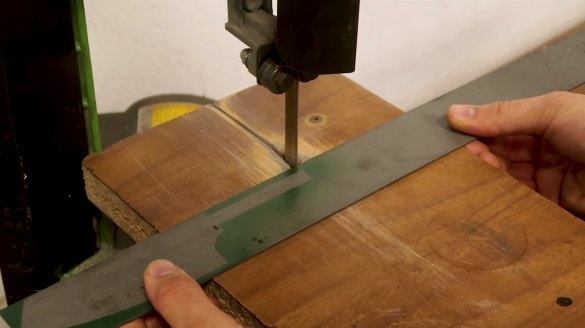

Step one. Making a knife profile

First of all, draw a knife profile on paper and transfer it with a paint spray to steel. Now you can start cutting, our steel has not yet been hardened and is easily cut. The author works with a tape cutting machine, you can also work with a hacksaw for metal or, in extreme cases, a grinder. You can refine the blade on a belt grinder, as well as a drill and files.

On the blade there is an interesting pattern for forging, in order to get it, first we grind the knife well with an emery cloth. Well, then you need a hammer with a rounded drummer, with the help of frequent strokes we form multiple dents on the blade. As a result, an excellent pattern is obtained, which will become more expressive after heat treatment.

Step Two Heat treatment

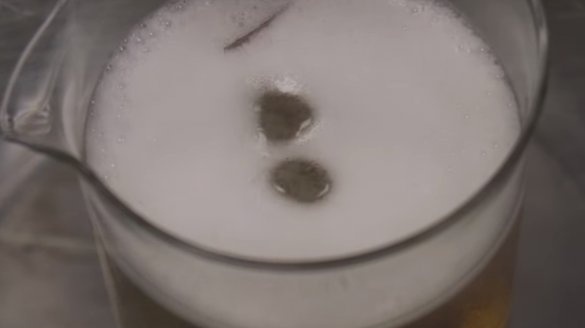

First you need to harden the blade, for this we need foil, and the author’s foil is clearly not made of aluminum, since such a foil would quickly burn out. The knife is packed in foil like an envelope and filled with white powder resembling a borax.

Well, then the blade needs to be properly heated to a red glow, and then we put it between two plates and blow it with liquid nitrogen on all sides. To harden such steel, a temperature of -80 ° C is required.

That's all, if everything is done correctly, now the steel is hardened. But you must remember to take a vacation in the oven at 200 ° C. The knife should be dominated by straw-colored tones. The maximum hardness of such steel can be 60HRC.

Step Three Grinding and polishing

We grind the blade after hardening, rough processing can be carried out on a belt grinder. It is also possible to form descents, in no case overheating the metal.

This is followed by careful manual processing with sandpaper, you can grind with water or WD-40. Well, then the author polished the blade on a polishing machine, the knife looks great.

Step Four Handle Parts

You can prepare materials for the handle, and the handle of the kitchen knife should not be afraid of water. To solve the problem, the author stabilizes a wooden block. To do this, you need the appropriate stabilization fluid, as well as a vacuum chamber. While air bubbles are released from the tree in the vacuum chamber, the wood absorbs the impregnation.

Before stabilization, the wood must be dried well in the oven.

Then the bar is wrapped in foil and sent to dry in an oven at a temperature of 95 ° C. After drying, the bar remains to grind, you get beautiful and durable wood.

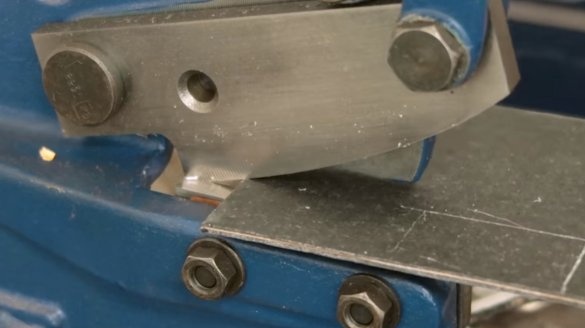

The author also has inserts in the handle, they can be made of G10, textolite or other material to your taste. If desired, you can make a guard, as the author. It would be nice to use stainless steel or brass.

To fix the shank of the knife in the handle, the author drilled a hole in the bar. But our shank is not round, and in order not to bore the hole, the author cut a slot in a round stick that is mounted on the shank. On the shank, it would also be nice to cut a notch for reliable bonding.

Step Five Stick assembly and completion

We assemble the handle, grease all the parts to be glued well with epoxy glue and tighten the entire structure with clamps during drying.

Well, then everything is the old fashioned way, we grind the desired profile of the handle and grind it well to a smooth state. At the final stage, cover the handle with oil, now it looks delicious.

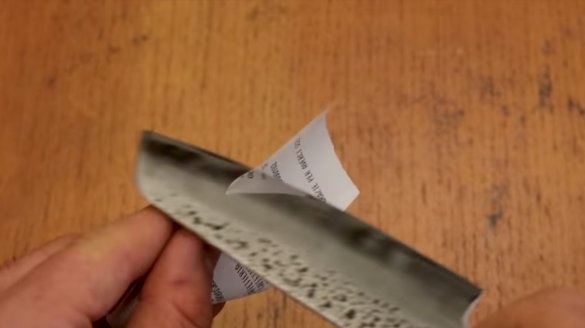

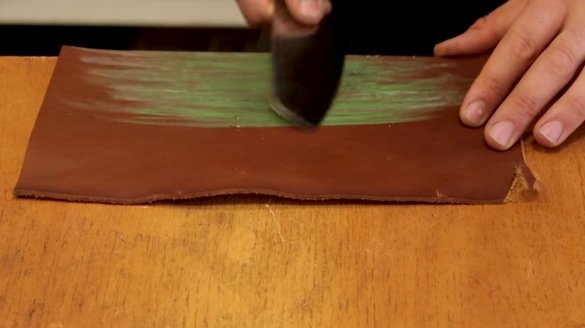

The knife is ready, it remains to sharpen it. To make the blade like a razor, the author sharpens the knife with a polishing paste on a piece of leather. The knife turns out to be very sharp, it cuts a thin check, and also shaves the hair on the hand. Of course, thinly chop the tomato, for such a knife is not at all a task.

This is the end of the project, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!