Frequency-response elements in undamped oscillators can be oscillatory circuits, RC chains, quartz and ceramic resonators, and tuning forks. At one time, we tried to use tuning-fork generators in watches (type “tuning-clock” in Yandex, you will find out a lot of interesting things), since they work at sound frequencies and do not require dividers. But then it was possible to make the frequency divider miniature and inexpensive, which is why quartz watches were widespread, and tuning forks were forgotten. The author of Instructables under the nickname WilkoL decided to make a tuning fork and feel like an experimental watchmaker in the sixties. The tuning fork is taken by the master, it is shown in the photo below:

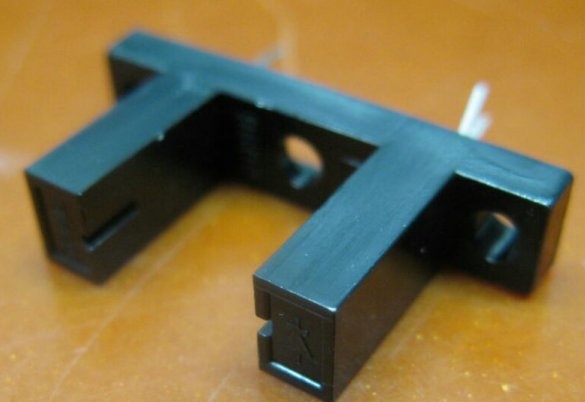

From his handle, the master cuts off the ball, and on the remaining part cuts the external thread, why - see later. To obtain undamped oscillations, it is necessary to ensure the supply of energy to the tuning fork from the outside. But not as horrible, but in sync with the already existing fluctuations, for which we need a feedback sensor. The master experimented with windings, Hall sensors, but each time he received a parasitic influence of the magnetic field from an electromagnet swinging a tuning fork. Finally, he opted for an optocoupler with an open channel. It looks like this:

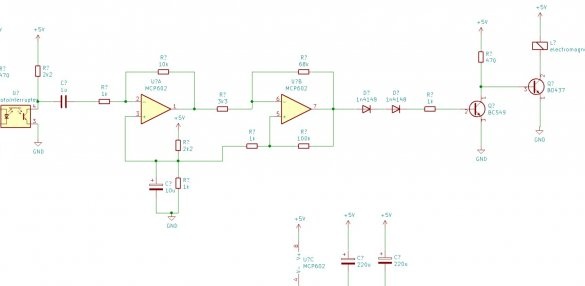

Now you need to connect all the components of the generator together: a feedback sensor, a voltage amplifier, a power amplifier and an electromagnet:

The IR LED of the optocoupler is powered through a 470 ohm resistor. The phototransistor load of the same optocoupler is a 2.2 kΩ resistor. Through a capacitor, passing only the variable component, and the resistor, the signal from the sensor enters the voltage amplifier. The master decided to use the MCP602 chip in it - a dual op-amp with single-field power. Despite the fact that it is dual, it has an eight-lead case. Each of the two op-amps occupies three conclusions, two more - plus power and a common wire, it was possible to meet exactly eight conclusions. The first of the op amps is included as an inverting amplifier, the second as a Schmitt trigger.

After a voltage amplifier, a power amplifier is needed, it is two-stage, with direct connection, and is made on discrete transistors. Its load is an electromagnet, coil data of which are not shown, only the active resistance is indicated - 22 Ohms. In parallel, an electromagnet needs a diode in reverse polarity, which the master decided not to set.

The chain of two diodes located between the voltage and power amplifiers is a threshold element that does not transmit signals with a voltage of less than 1 V. The resistor after it limits the base current of the first transistor. In principle, after the Schmitt trigger, the threshold element is optional, it is set just in case. All this made it possible to make the power amplifier key, dispensing with the heat sink on the second transistor.

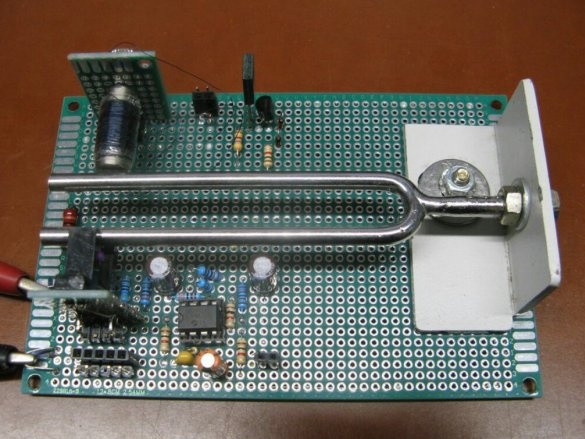

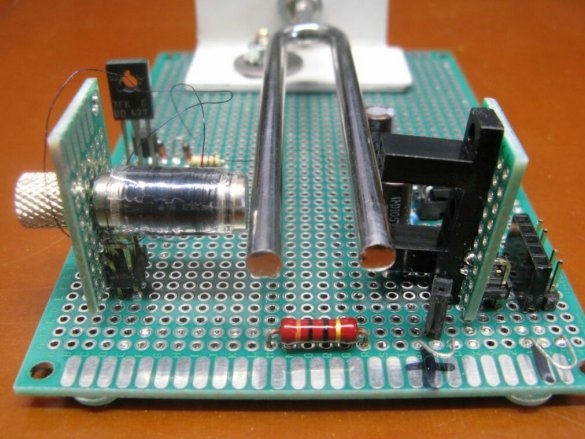

The master generates the generator on a protboard type perfboard, the optocoupler and the electromagnet are located on pieces of the same board, located perpendicular to the main one. To fix the tuning fork, a metal corner is screwed to the board, and a tuning fork is screwed to it for the thread previously cut on its handle.

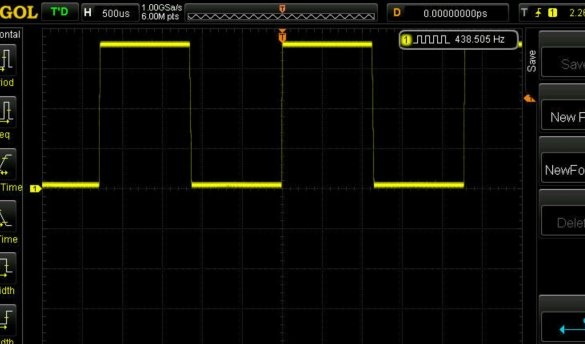

The adjustment of the generator is reduced to the selection of the position of the optocoupler so that at one of the maxima of the amplitude of the tuning fork oscillations its optical channel opens, and in the other it closes. The shape of the generated oscillations at the output of the Schmitt trigger is shown in the screenshot from the oscilloscope:

The tuning fork was tuned 1.5 Hz below the standard frequency of 440 Hz. This can be fixed with a file. The author was only interested in the tuning fork generator in its pure form; he did not begin to build a watch. The most common way to pair a generator with a watch is to use a gear with a very large number of tiny teeth. It is positioned so that with each oscillation, the tuning fork presses the tooth closest to it and rotates the wheel at a small angle, thereby bringing the next tooth to the tuning fork. The tuning fork clocks come only with a smooth running, they do not tick, but, depending on the resonant frequency of the tuning fork, they buzz or squeak.