The summer has not ended yet, and many want to please their children with entertainments at the ponds.

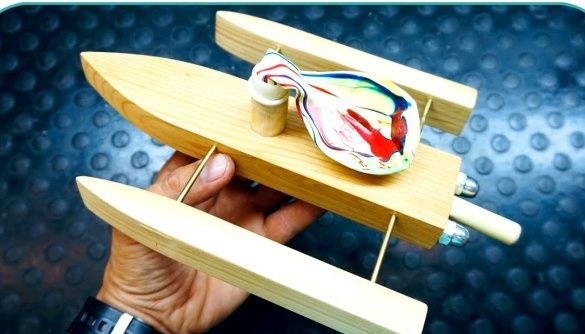

In this article, the author of the YouTube channel George Kosilov will tell you how he made a small trimaran, which moves due to the energy of the air.

Materials

- Wooden blocks

- Brass rods 3 mm in diameter

- M8 stud, blind nuts

- Balloon

- A wooden round log, or branch

- PVA glue

- Acrylic lacquer.

Instruments, used by the author.

—

- Feather drills for wood

- Belt sander

- Ruler, pencil, file, vise, hacksaw, hammer.

Manufacturing process.

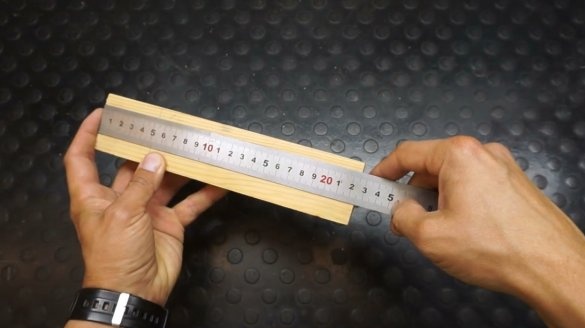

So, for starters, the master will manufacture the central part of the body. For him, he picked up bars of 225X50X25 mm in size.

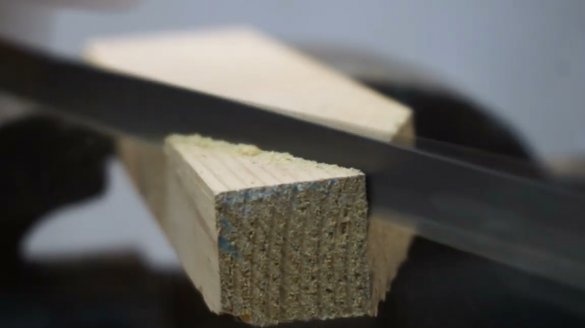

He pre-cuts the nose at an angle.

But these angles must be rounded off, a grinding machine is suitable for this.

Now you need to make the side floats from a thinner bar. He marks it “by eye”.

Sawing a bar into two identical workpieces.

In the same way forms the bow of the floats.

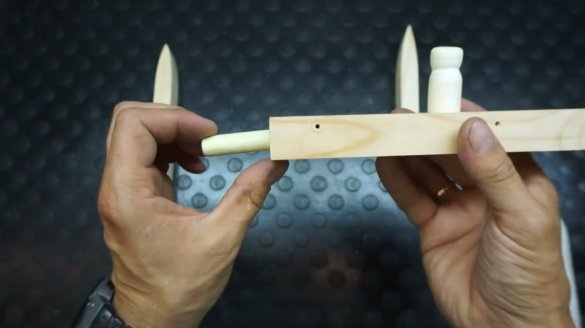

These are three blanks.

In the center of the main building, a blind hole is drilled with a pen drill with a diameter of 18 mm.

Now you need to make a longitudinal hole with a diameter of 12 mm from the stern to the first hole.

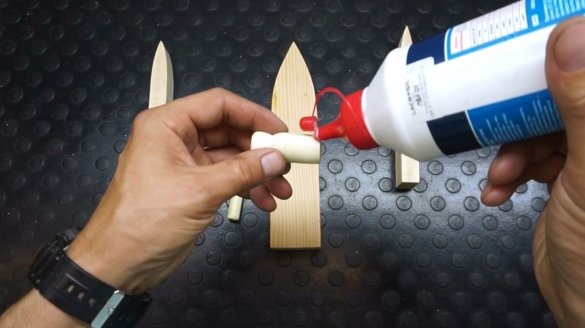

For the manufacture of the following parts, a small piece of branch is suitable. A small groove is made in the nozzle with a file.

These items are nozzle and fitting.

The fitting is glued into the central hole.

And the nozzle is mounted aft at a slight angle.

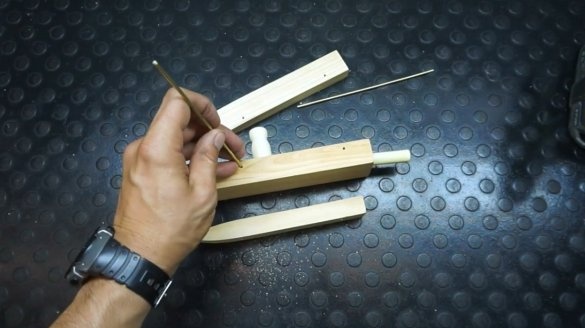

Now you need to fix the floats to the body. To do this, drill holes with a diameter of 3 mm. In the floats they will be deaf, and in the body - through.

In order to connect the parts to each other, two brass rods of 3 mm diameter are suitable.

After assembling the case, it must be covered with acrylic varnish. It is advisable to do this in several layers. It will help protect the boat from the effects of water.

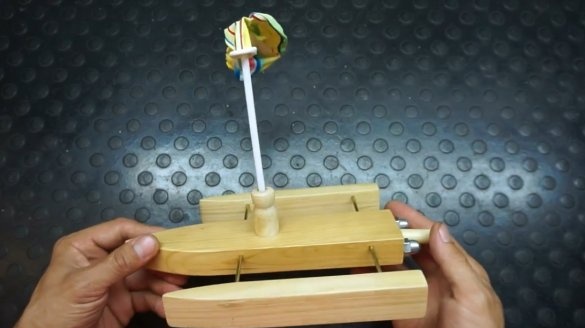

So, the varnish is dry, and the trimaran looks like this.

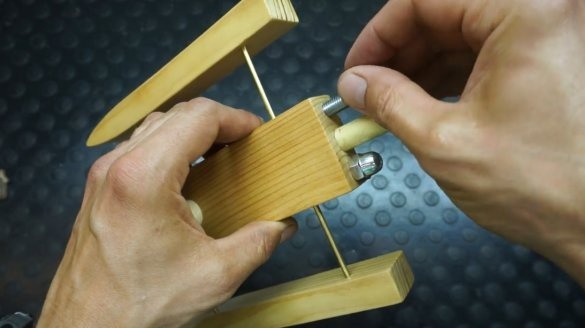

Then the master made two holes in the stern, and cut the M8 thread into them.

Then he took a steel stud M8 and two blind nuts. The hairpin is cut into two parts. A weighting agent will be made of these parts. They are screwed into the stern. This is necessary so that the bow of the ship is slightly lifted, and the nozzle is under water.

It remains to put on the ball fitting. It is so that he does not jump off and a groove is made.

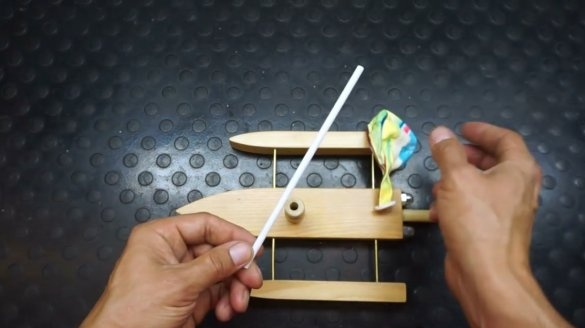

So you can experience. It does not swim very fast, but confidently.

During the tests, one problem turned out - the ball bent to the side, and the boat turned. To keep the ball in an upright position, the author inserted a regular plastic tube into the fitting. Being inside the ball, she holds it.

Thanks to the author for the simple but very interesting idea of the trimaran model!

All good mood, good luck, and interesting ideas!

Author video can be found here.