Large, spacious, with many drawers and shelves - this is the table that is needed for sewing. The master made it for his wife, and shared with us the main points of its manufacture.

Tools and materials:

-A circular saw;

-Jointer;

-Circular Saw;

-Drill;

- Jigsaw;

Milling cutter;

-Band-saw;

-Grinder;

- Chisels;

-Rasped;

-Plywood;

-Board;

-Furniture guides;

-Fasteners;

-Sewing machine;

-Plexiglass;

-Finishing material;

- Clamps;

- Joiner's glue;

- Electric hammer;

Step one

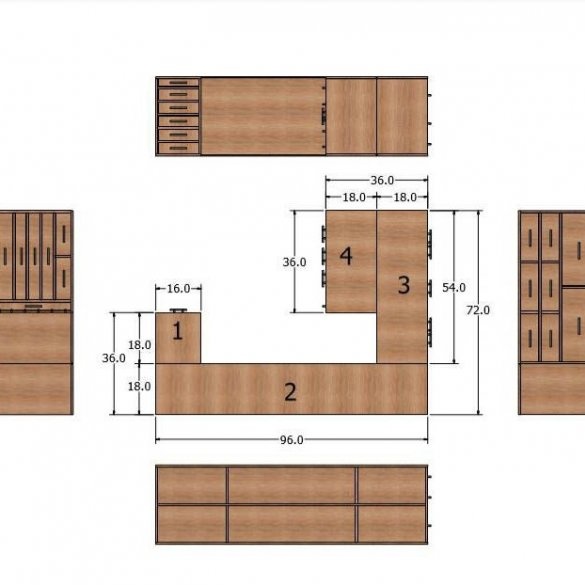

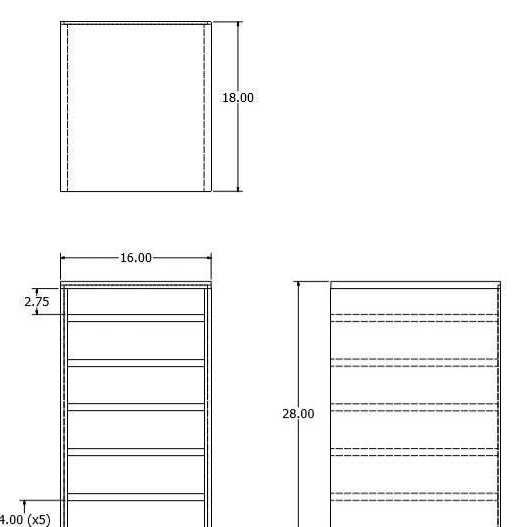

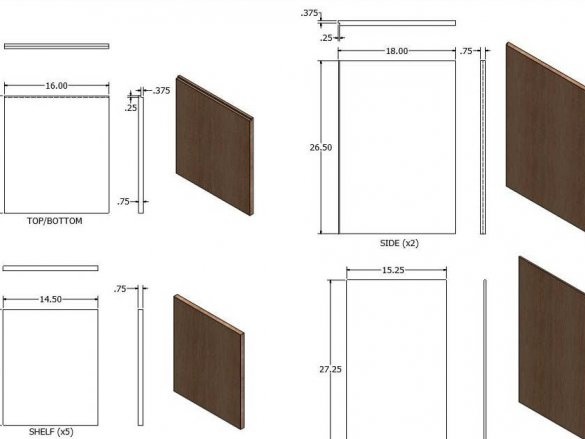

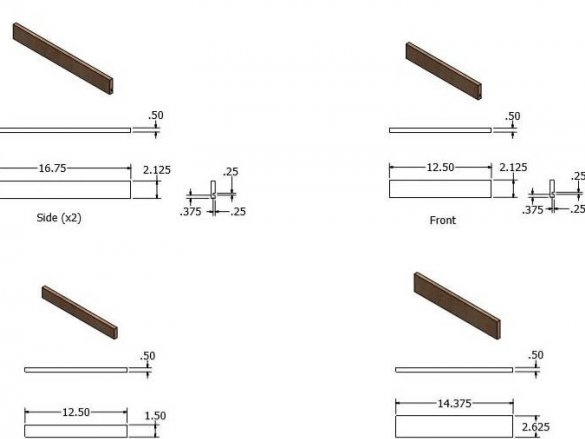

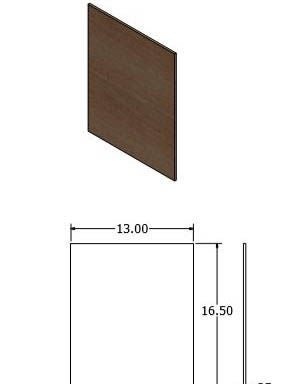

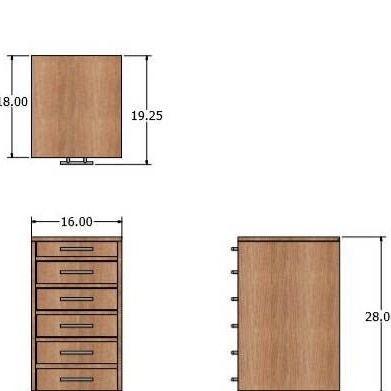

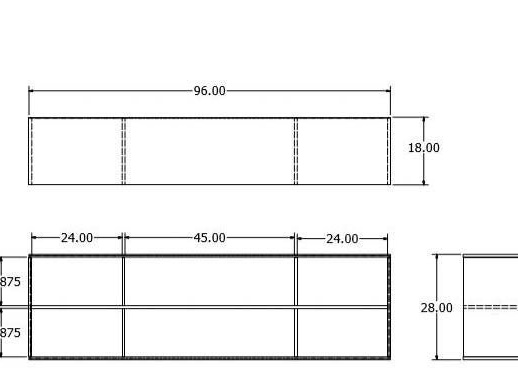

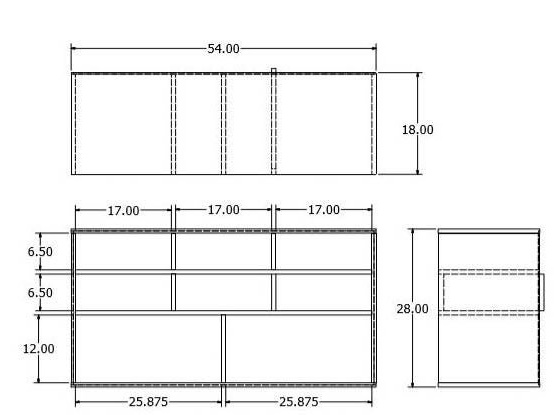

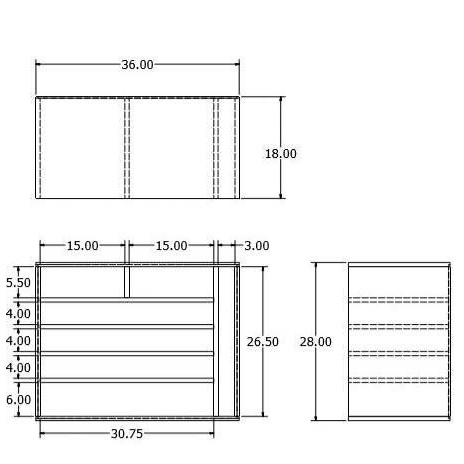

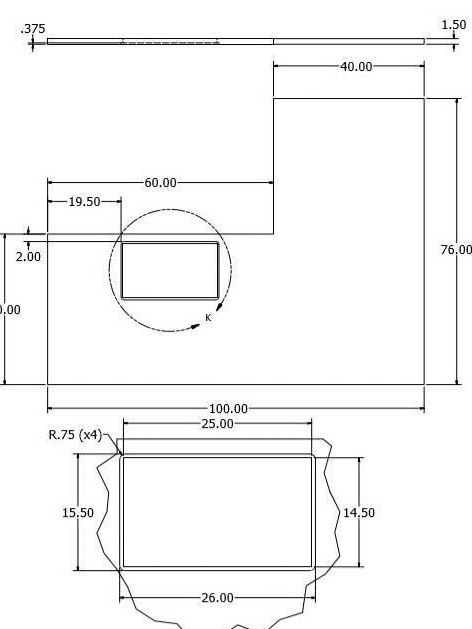

Drawer sections have the same design but different sizes. The plywood is rough cut to the desired size using a circular saw, and then cut to the desired size using a circular saw. The width of all sections is the same, the length is different. In the drawing, all dimensions are in inches.

Connect the parts using liquid nails and staples. After assembly, the edge is glued.

Second step

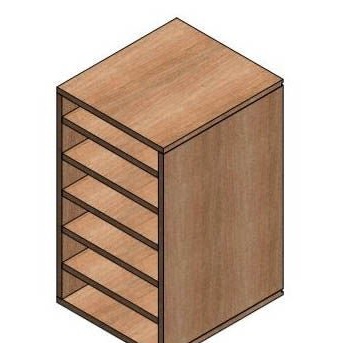

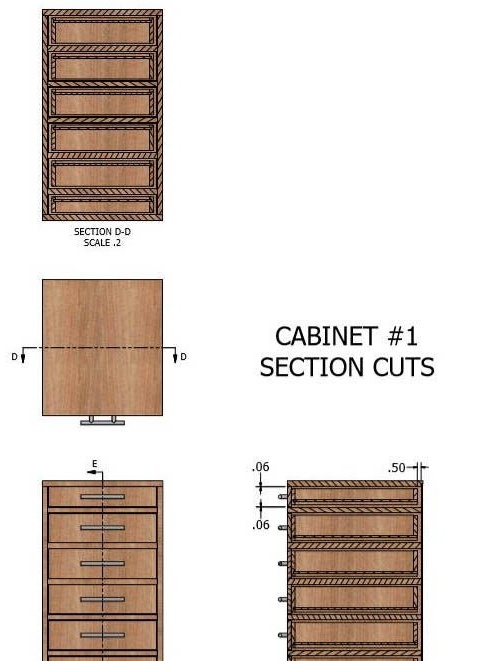

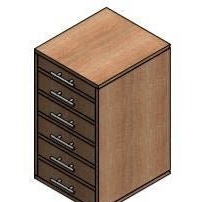

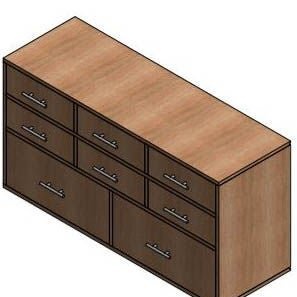

The first section is a small cabinet with drawers, which will be located to the right of the table.

Step three

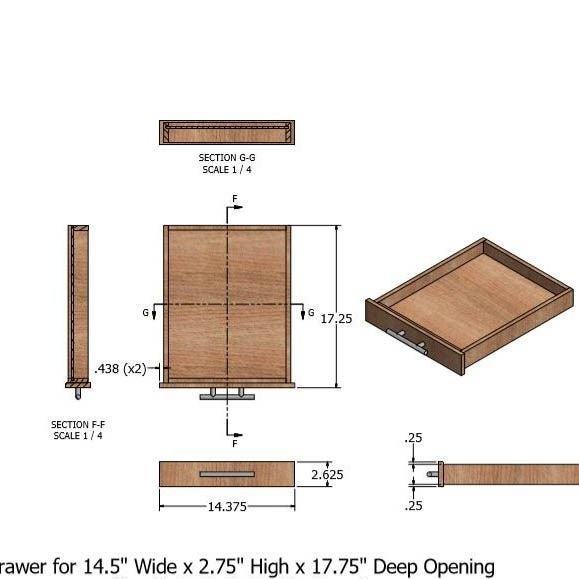

The drawers in each cabinet are of different sizes. The assembly of boxes is made according to the drawings.

The front panels of the drawers were cut to size and installed in such a way as to provide clearance from all sides. Handle holes must be drilled prior to panel mounting.

After assembly, the master polishes the boxes with the 180th sandpaper and applies the finishing coat.

Fourth step

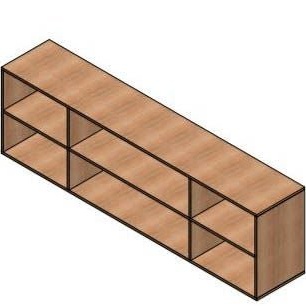

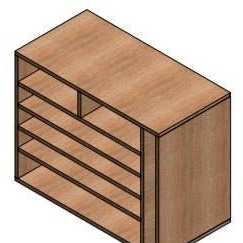

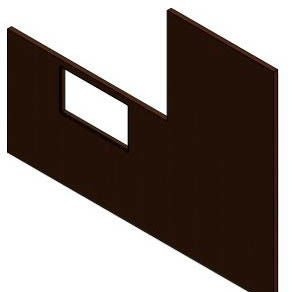

The back of the table does not have drawers and is designed to store various boxes.

Fifth step

The side part consists of two sections, and has a number of drawers, both rear and front.

Sixth step

The countertop is made of boards. First, the master rounds the boards and adjusts to the same thickness. Then the boards are cut to size and glued together. The countertop is fixed on the base.

For the sewing machine, the master cut a hole in the countertop and installed a lifting mechanism

The table for the seamstress is ready.