Good day to all. Today, the author of the TeraFox channel will show us another version of a home-made stove of grate, which the author made of two old fire extinguishers.

MATERIALS AND TOOLS:

Fire extinguishers (empty.)

Vise

Sheet metal;

Paper;

Scotch;

Marker;

Angle grinder;

Cutting wheel for metal;

Plazmorez;

Electric drill and drill;

Hammer;

Bolts and nuts;

Sandblasting machine;

Welding machine and electrodes;

Square;

Ruler;

A piece of profile pipe;

Spring;

Wire;

Gas-burner;

Heat resistant enamel;

Clamps;

Door chain;

Pliers;

Spanners;

Scissors;

Safety precautions: respirator and goggles.

And so, the author, began to manufacture his homemade. First of all, he decided to unscrew the cranes from the fire extinguishers.

But this task was not easy. And the author, having thought a little, understood that this cylinder does not pose any danger and it can be cut without removing the tap.

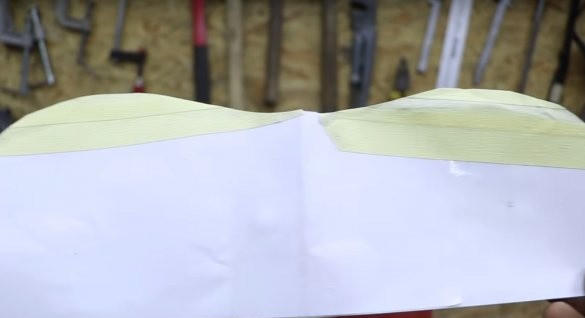

After, the author took a piece of paper.

And wrapping it with a balloon, he fixed the edges with tape.

Then, with a marker, he made markings on the cylinder.

After removing the paper.

Cut off the excess.

Further, the author made such a layout template out of paper to subsequently dock a cut to the side of the fire extinguisher.

The author carries out these manipulations on the second fire extinguisher, in its lower part.

After plasma cutting, it cuts according to the markup and disconnects the excess.

Like that.

Now it’s not much easier, the fire extinguisher itself acts as a template, by applying which the author outlines the border of the future cut.

Then deletes the unnecessary.

And cuts the edges.

Then, from a sheet metal with a thickness of 4 mm, the author needs to cut the part in the shape of a circle.

Given the wall thickness of the fire extinguisher, which is 6 mm.

After I cut this blank.

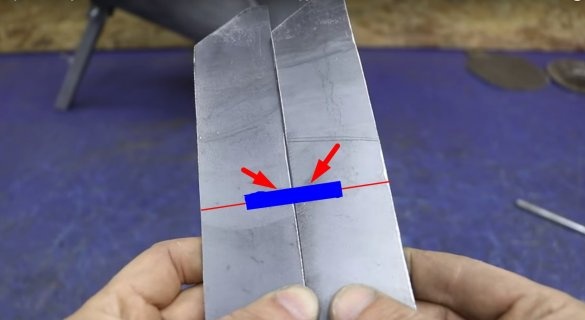

And I made such a marking on its surface - these are the lines of longitudinal holes. The distance between them is not large and the author will have to try to make them neat.

But first, he would drill holes.

And only then, makes cuts using angle grinder.

The result is such a detail.(Grate)

To fix the grate, the author welded three bolts inside the cylinder. Since the grate will burn out sooner or later, the author decided to make it removable.

Fitting.

Next, the markup again.

And removing the top of the fire extinguisher.

Further, the master will again make a sheet of sheet metal. Everything, as in a template, is first marked up.

After cutting out the details.

Further, this detail, the author will weld into the workpiece from the second fire extinguisher.

Like this.

Then the master will make a marking under the slot in the lower part of the first workpiece.

After drilling holes.

And then the slot itself.

The author decided to make a removable partition with a handle protruding from one of the sides. The author will also do it from sheet metal, cutting out a part of a suitable shape.

Then he will make a hole as shown in the photo.

Fitting.

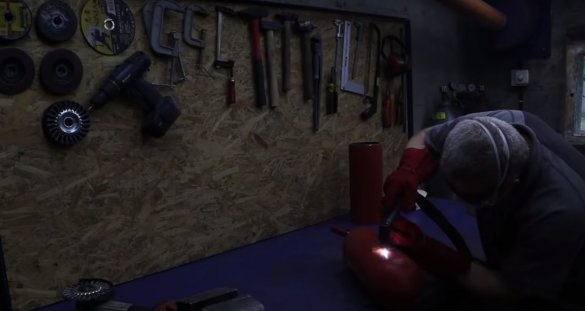

Further, the author connected both parts of the fire extinguishers and grabbed a pair of welded points.

After making sure everything is smooth.

Welded the connection with a continuous seam.

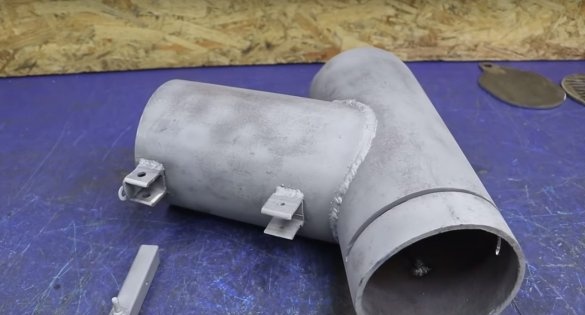

Then the master decided to give stability to the whole structure. To do this, he made a leg from the sections of profile pipes and fastened to it. The leg itself is rounded on one side so that it can fold seamlessly.

Set the leg, the author will be in this place.

Welding the legs fasteners.

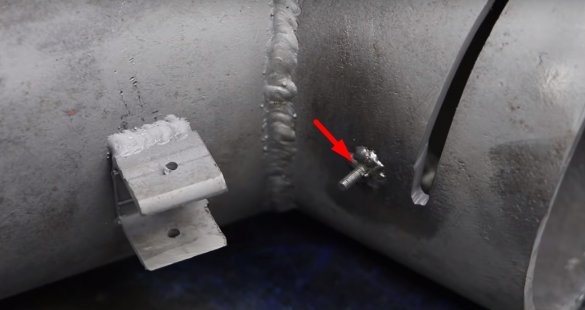

The author will install the leg and fix it with a bolt.

Then the master added a spring for fixing. The washer and bolt act as spring fasteners.

Further, it would not hurt to make a latch that will hold the leg in the folded state. And not a large section of a profile pipe can easily cope with this.

For a complete picture, the author will also make a check from stainless wire, such as it was in an unused fire extinguisher. The stainless steel wire is very stiff and the author has to heat it first and only then deform it.

Now you can lock the leg with a check.

And activate if necessary. It’s quite a working solution.

Further, the author removed the remaining paint.

All elements are ready for painting.

But there remains one more detail that the author needs to do. And this is a cross-shaped stand in the upper part of the furnace. For its manufacture, the master uses the same sheet metal 4 mm. Makes a template and transfers it to metal.

Then cuts out two absolutely identical parts.

In order to install them on top: you will need an asymmetric arrangement of the slots in the middle. First: the author finds the middle.

Then he makes holes.

And then a slot.

Assembly.

Fitting.

Also, after trying on, the author will make 4 slots for fixing the cross on the surface.

The author succeeded, and the result is quite satisfactory.

Now for sustainability. According to the author, the oven turned out not to be shaky, but just in case, the master decided to play it safe. And add the cross member to the base. 50 mm of the twentieth and 200 mm of the fifteenth profile pipe. Solve the issue of furnace stability.

The author welded a short piece of pipe to the base.

And it is already installed in it, that piece of pipe that is longer.

In order not to lose a check somewhere in the grass, the author found a simple solution.

He took a piece of the chain and placed a check on one of its edges, and he will attach the second end of the chain to the furnace body.

For this, the author was not welded a large bolt to the body.

But perhaps that's all, it remains only to paint all the details.

After painting the parts, the master assembled the furnace.

Then he made a couple of holes and installed a handle from the wire to carry the furnace.

Such an oven turned out by the author.

Well, now the test.

Perhaps many will say that carrying such a massive stove is unpleasant. Yes, the furnace turned out to be really weighty, but on the other hand, there will be no demolition of this furnace.

Many thanks to the author for such a good home-made.

And that’s all for me. Thank you all very much and see you soon.