Hello to all lovers of working with steel, today we will consider how to make a beautiful knife from Damascus steel. The blade is made of only two grades of steel, this is 1095 grade steel, as well as 15N20 steel. Homemade not difficult to manufacture if you have blacksmithing tools and work skills. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- steel plates of the brand 1095 and 15N20;

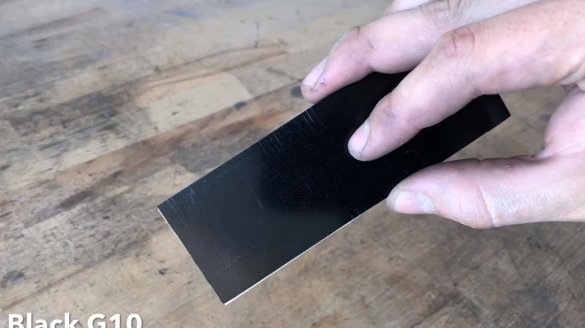

- G10 and wood for linings;

- carbon fiber rods (for pins);

- epoxy adhesive.

Tool List:

- instant coffee;

- ferric chloride;

- oven and blacksmith tools;

- grinder;

- welding machine;

- borax;

- belt grinding machine;

- vernier caliper;

- drilling machine;

- oil, oven (for hardening);

- sandpaper.

The process of making a knife:

Step one. Preparation and forging

To begin, we cut steel plates, put them in a stack and weld. Of course, we alternate steel to get a beautiful damask pattern. As a handle, we weld a piece of reinforcement to steel, and now steel can be heated. After warming up, sprinkle brown steel and proceed to forging. Without borax, steel will mix poorly, and it is extremely important for us to mix it well.

We cool the workpiece, cut off the excess and send it back to the oven, mix steel plates well into a homogeneous mass.

At the final stage, the author with the help of a grinder grinder makes cuts in a steel bar, and then forges steel. Thanks to this procedure, we get beautiful stripes on the blade. When everything is ready, we form a blank from steel, resembling a blade. After forging, it is recommended to normalize and temper the steel so that it does not lead during processing.

Step Two Grinding and holes

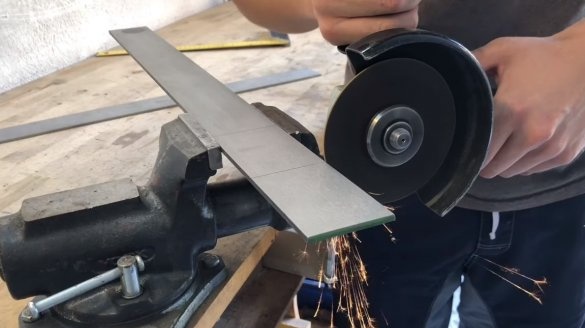

After forging, we cut the reinforcement with a grinder and modify the profile of the blade by grinding on a belt grinder. As a result, we get an excellent blank for a knife. We make markings in the area of the handle and drill holes for the pins on the drilling machine.

Step Three Slopes

We form descents on the blade, for this we do the marking with the help of a caliper. It is extremely important for us to draw a central line along the blade, on which we will rely on when grinding. Well, then we remove the excess metal, the author uses a special holder for the blade. As such a holder, you can use a piece of corner.The blade is not yet sharpened, hardening is ahead, thin metal can burn out.

Step Four Heat treatment

We heat the blade in the furnace to a bright red glow, when heated to the desired temperature, the steel ceases to magnetize. Next, immerse the blade in oil, you can use automotive working out.

After hardening, the steel should begin to ring, and it will not be taken with a file.

To prevent steel from being brittle, we leave it in the oven at a temperature of 200–205 ° C; it takes about two hours to heat the blade. The oxide film on straw-colored steel will tell you about the right vacation.

That's all, the heat treatment is done, it remains to thoroughly clean the blade from burning and sanded with sandpaper to shine.

Step Five Lining

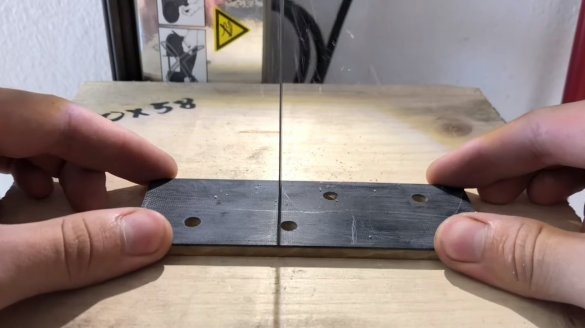

We make the pads for the knife, as planned by the author, the pads should be slightly smaller than the steel handle of the knife. Thanks to this approach, you can even hammer with a knife.

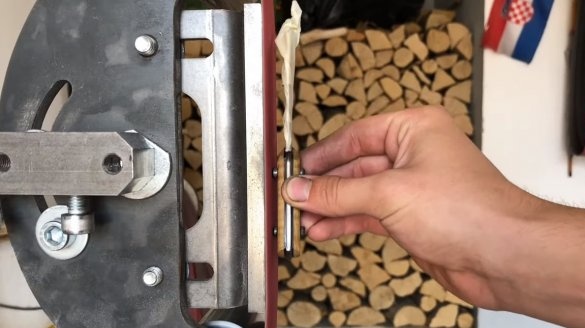

As overlays, G10 glued with stabilized wood was used. Having prepared the material, we cut out the pads from it with any suitable tool. Black pins made of carbon fiber will look nice as pins. The lining remains to be finalized on the LSM, and we grind them to a smooth state using sandpaper.

Step Six Etching

To highlight the pattern of the blade, immerse it in ferric chloride. For the reaction to go well, the steel must be well degreased. After that, we wash the blade with soda, soda will neutralize the reagent.

To make the picture as bright as possible, immerse the blade in concentrated instant coffee. Thanks to coffee, dark tones will turn black and the steel will look great. Rinse the blade well under running water and leave to dry.

Seventh step. Assembly

We assemble the knife, we need epoxy glue, glue the handle with it and wait for the resin to solidify. After that, the knife will be ready, it will have to be sharpened, here water grindstones will help you.

The homemade product is ready, the knife looks delicious, and it will also cut very well. With this knife you will surely surprise your colleagues in the "silent hunt" and not only. This is the end of the project, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!