This article will show you how to do it yourself make an original plate. The author of this project is Maxim Kozlov (YouTube channel "Maxim Kozlov").

We will grind the plate from such a lime tree stump:

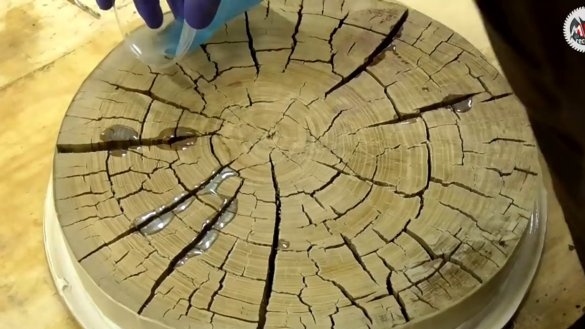

This stump stood for several years in the open and cracked pretty well. At the beginning of summer, when the weather was still pleasing, the master withstood the stump under the scorching sun and roasted it well after winter, after which he brought it to the workshop. In the workshop, the stump was waiting in the wings for about a month. And now, having cut off the upper part, where there was a maximum number of cracks, we can begin to prepare this part for subsequent pouring with epoxy resin and processing on a lathe.

When cutting a stump, there was a high probability of breaking the round log into pieces, but here the author was lucky. Well, if the stump still fell apart, then this is not at all scary, since you can glue everything in parts to the base of plywood.

Next, we saw off all the excess, giving the workpiece a circle shape.

Then we drive the product through a drum grinding machine to set normal parallel planes for gluing the workpiece to the base and saving in further pouring, that is, not to pour the resin into unnecessary cavities, but to fill in only cracks.

When grinding on such a machine, you should always unfold the workpiece with each pass so that the fibers do not chip in the same direction inside the cracks. Chipping is not characteristic of a drummer, but for a soft shabby linden such an effect may be present.

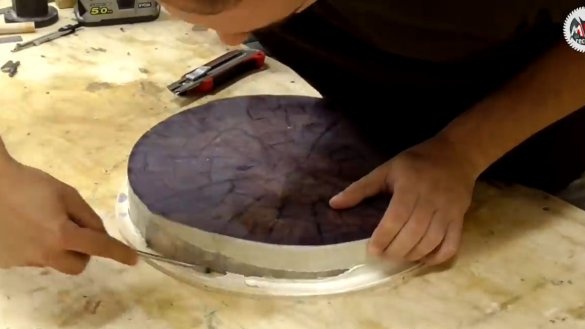

Next, from the 6 mm plywood, cut out the base for pouring. The circle should be made a few centimeters of a larger diameter than the workpiece itself.

Then we glue the workpiece to the base and set the shape for filling with masking tape in a couple of revolutions.

As you can see, the 10-mm adhesive tape just covered the thickness of the workpiece. Further, everything is according to the classics, sealing with silicone sealant, followed by rubbing with a finger. Thus, the absence of leakage is guaranteed by almost 100 percent.

The first batch of this stump went to the remnants of resin from another product. Kneading was made with the addition of metallic pigment.

Continue to fill was decided by the same composition. Metallic pigment gives a pretty good effect.

After 24 hours, the product was completely ready for processing.We release the workpiece from the sealing elements and saw off the excess diameter of the substrate, which simply would not fit into the lathe in the maximum diameter, and the diameter of the workpiece, meanwhile, was about 360 mm.

Then we fasten our workpiece to the faceplate and install it in the machine.

Literally from the first minutes of turning it was clear that the work ahead was not easy. The lime tree stump, which had been there for several years under all the rains and snows, was not to say that it rotted over the entire upper layer, which was flooded, but at least turned into something like cotton wool. Because of this, the workpiece is pretty much chipped.

Having freed the blank from the plywood substrate, the master was pleasantly surprised by the quality of the resin spill, which filled absolutely all the microcracks. Most likely this happened precisely due to the dried out structure of the wood, and the resin could spill everywhere, otherwise in this case an excess pressure chamber would be needed to obtain the ideal result.

But the loose structure of the tree in this case is not in our favor, and even with an external groove, you can see that the whole story is sharpened like linden with resin, that it is about the same in hardness, and much worse, and it’s pretty quick to plant cutters .

Next stage - grinding. It was necessary to grind decently here, the 40th abrasive even had to be pressed through a wooden block to strengthen the effect. The only thing was that we had to periodically cool the workpiece with compressed air so that the resin did not crack, while at the same time blowing out the potholes.

If a reverse were present on the machine, then with it the whole process would be reduced by half in two for sure. Nevertheless, all the chips were defeated and finally you can see how all this will look under the oil.

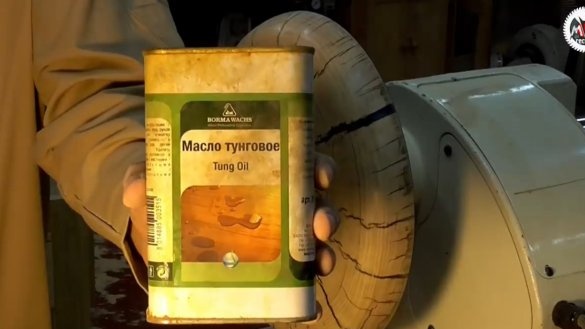

The tung oil, for all its density, was absorbed into the end of a loose linden like a sponge and asked for more and more. After a couple of layers, it was decided that for the first side it would be enough. Further, the author proceeded to cover the product with wax.

Please note that the ledge under the cartridge should not be pre-coated with oil so that the workpiece does not slip on it.

Despite the rather dirty and heterogeneous structure of the wood, while partially affected by fungus and rot, everything looked very interesting and unusual in general.

With the outside finished, you can proceed to the internal groove. Installing the product in a cartridge, at first everything was like clockwork and even fun, but it did not last long until a clean layer of resin was sharpened and kilometer-long confetti flying straight in the face created an excellent warm hat on the head.

The fun ended when the entire layer of resin from the surface of our product was grinded off and the cutter ran into something previously unknown. Actually, turning, scraping and other turning processes just stopped. The master had the impression that he was driving a glass cutter. And this is a linden for a minute.

Then all the cutters that were suitable for these tasks went into the course and they all could not hold out for more than 10 seconds. A crazy thought even flashed through the master’s head that this stump was cursed, but looking at the cutting part of the edges of the cutters, it became clear that they were dull by a layer of metal pigment, which settled on the surface of the wood when pouring.

Thus, a rather effective grater for incisors was obtained, which killed them literally before our eyes. But still, somehow, without turning off the sharpening machine, the author somehow managed to break into the workpiece, but the problem did not go away completely, it became easier, but by half.

It turns out that a rather loose linden missed the metallic pigment not only into the cracks, but also into its own pores. In general, this case is rather strange, since recently the author sharpened a couple of products with rather wide sections of resin with the same metal pigment, but there the resin was poured between the longitudinal layers of wood and could not get into the structure. And here the conclusion suggests itself that it is the end blanks with a porous structure that cannot be filled with resin with metallic pigment.

As a result, I had to grind everything in microsteps. At the same time, I had to push quite hard.

In general, after a few hours, the master nevertheless managed to bring out the desired inner plane.After that, he started grinding.

During grinding, all the potholes that were not defeated during grooving were completely eliminated by the fortieth grain. True, I had to spend a couple of hours on it, it turned out a real marathon for endurance.

As a result, the author was satisfied with the result. Nevertheless, we can safely say that it was one of the complex turning projects. So such an experiment turned out, plus experience and a treasury of knowledge. Thank you for attention. See you soon!

Author's video: