Hello everybody! Today I found in my workshop a sheet of hacksaw for metal, by the way, this sheet was made back in the USSR, thereby this metal is not the same as today’s in the sheet. The canvases that are sold today are literally disposable, cut off a piece of aluminum pipe and that's it - half the teeth are gone, these are the things.

But in general this is not the point, let's get to the point. The knife was made after all my Chinese scalpels broke and needed to be replaced with something, but the steel is stronger, thicker and not so fragile. Well, I also noticed that this Soviet one does not crack like today. Tools for manufacturing may not be the most affordable, but I think you can get by with a drill or drill with a nozzle on a circle for a grinder. Well, the handle can be made from a branch or taken from an old file. Let's get started!

The very first thing you need to do is apply a template (drawing) for cutting. I pasted a masking tape on which you can clearly see where to cut, well, of course, you can apply white paint and already draw a drawing there.

An ordinary pencil is clearly visible on white scotch tape, but you can also use a pen, marker, well, that’s not the point. Well, we get to the stage of cutting with a grinder, if you, like me, cut with a grinder, then we fix the canvas on the countertop, where are we going to cut, and fix it with a clamp so that for sure not to cut something for ourselves and so that something does not fly head-on. At this stage, very neat!

After we already held the most dangerous the robot for a beginner, you need to remove all sharp edges that can cut your fingers when processing the blade. Well, align the edges on the grinder or on the grinding tank, like mine. Here is also an important stage, not to overheat the metal so as not to play later and not to heat it; therefore, we dip it into the water in parallel.

Well, we also clean the rust and old paint with different types of sandpaper, bringing to the desired result.

After polishing, you can sharpen the blade to the desired sharpness. I grind on a makeshift sharpener, grind with sandpaper, but best of all on stones. But the stones are expensive and fragile.

Lever.I made a handle from a dry branch of a nut, I also turned it on a homemade lathe, and varnished it. To avoid roughness, I clean it with sandpaper for 2000.

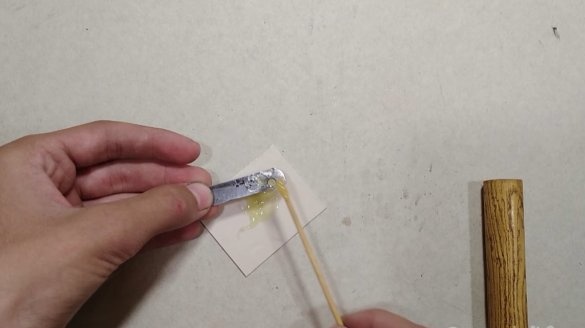

Now closer to the finale. We glue the blade into the handle, I make it with MetalBond glue, it freezes in a few minutes.

Well, finally, I finished this knife. I did it throughout the day for a bit. The knife turned out very sharp and holds sharpening well. I recommend it to everyone, and even more so who do not have scalpels. You can also watch a video on the manufacture.