I was mistaken in claiming that the author of Instructables under the nickname WilkoL made his tuning fork generator for the sake of the generator itself, and the clock does not interest him. This turned out to be wrong - his next homemade it was the watch with such a generator that became steel.

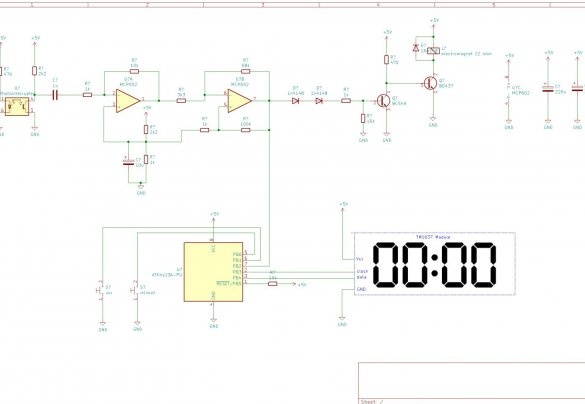

Let me remind you that the classic way of pairing a tuning fork generator with a clock is to use a gear with a very large number of tiny teeth, which is rotated through a very small angle with each tuning fork tuning. But the master decided to crank up a little cheating and connect to the generator electronic clock. The layout has changed like this:

Now it has a diode in reverse polarity parallel to the electromagnet - probably the master ruined one output transistor and realized that such a diode was needed. And also the components of the watch itself are added - the ATtiny13 microcontroller and the TM1637 display module. The principle of operation of the generator and the procedure for its adjustment are discussed in the previous article. A ZIP archive with microcontroller software (written in AVR Studio 7) is here, Well-readable PDF file - here.

In order not to disassemble his previous homemade product, the master takes another tuning fork, also at 440 Hz:

Just as in the previous case, a ball is sawn from his handle, and an external thread is cut on the handle itself. But the fastener makes it more beautiful, with its internal thread, so that nuts and washers are not needed:

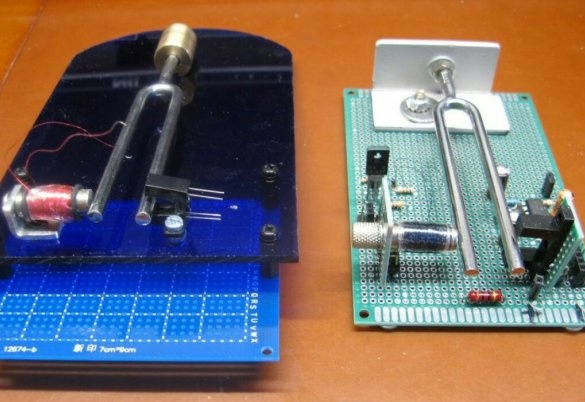

Tuning fork, mounting element, base, empty circuit board, electromagnet and optocoupler next to the previous tuning fork generator, which is already set up:

The master enters the Action store - an analogue of "Fix Price" in the Netherlands, Belgium, Germany, France, Austria, Luxembourg and Poland. There he acquires a lamp in a decorative bulb. The lamp removes, there remains a bulb that visually resembles a balloon of a large radio tube:

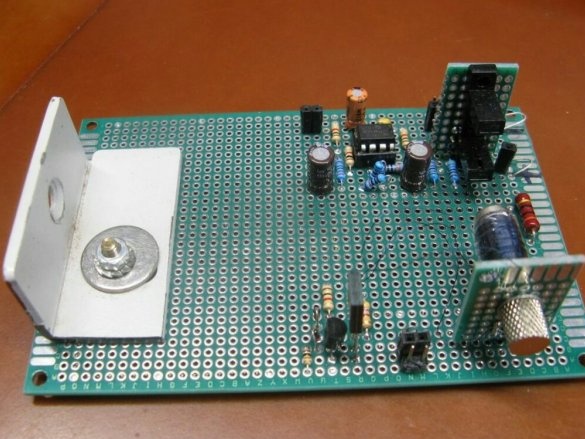

The master takes the microcontroller:

Display module:

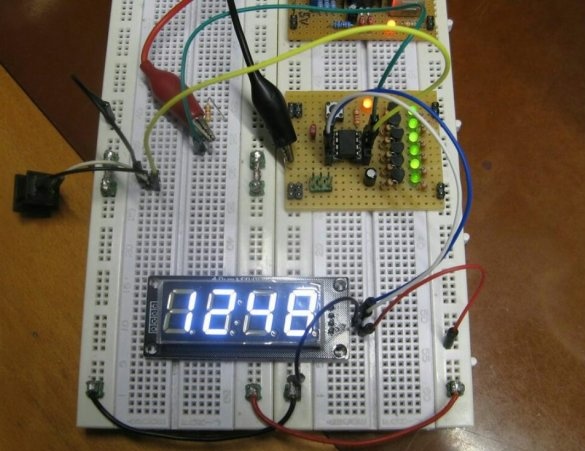

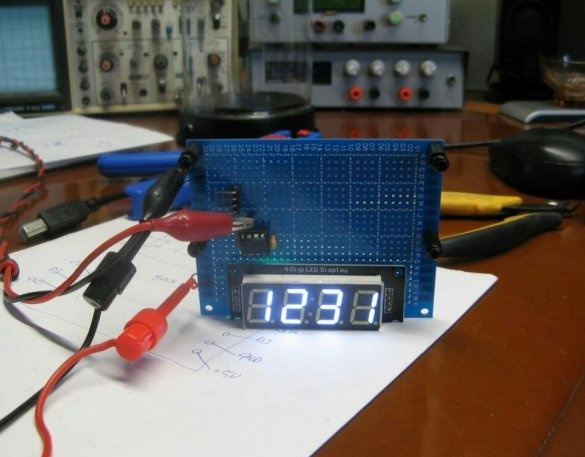

It flashes the microcontroller, checks everything on a breadboard type breadboard:

Ports to a perfboard type board:

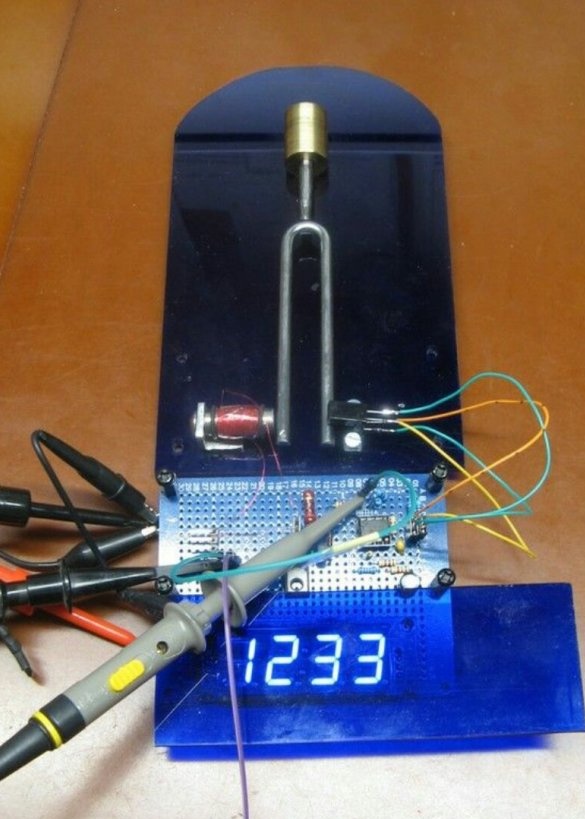

Following the hour part, it collects the generator room and installs the board in place:

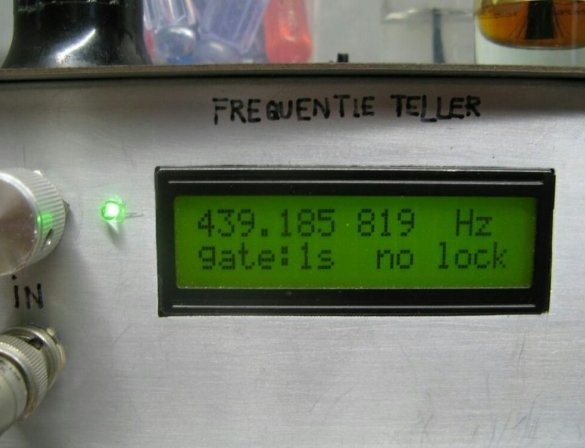

Connects frequency meter:

He begins to adjust the tuning fork with a file, and ... breaks, he is red-hot:

I had to remove the tuning fork from the previous generator, you can buy another one over time.

And there the thread is different, and the fastener had to be made new. Finally, everything is configured (with more caution), and the clock works:

The master managed to achieve the exact frequency of 440 Hz at 25 degrees Celsius. The temperature stability of the generator is low, a thermostat will be a good addition to it.Then the generator will have to be adjusted at a temperature above room temperature - for example, 50 degrees, and then thermostat should maintain this temperature.

The watch is ready:

The buttons are installed in the stand of the bulb. But the vertical plexiglass base turned out to be too effective a membrane, which makes the watch hum. The master plans to vibro-isolate the tuning fork from the base, while he turns on the watch only when he wants to show it to someone.