Greetings to the masters of fire and hammer, today we will look at how to make a large two-handed chisel. The author made a knife from an automobile spring, and the handle was made of multilayer plywood, which was impregnated with a liquid for normalization. The tool turned out to be very strong, it works great and looks great. With this chisel, you can make large grooves in the logs and much more. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- car spring;

- a piece of steel pipe (possible from the bed);

- plywood;

- glue;

- liquid for normalization.

Tool List:

- belt grinding machine;

- grinder;

- oven and blacksmith tool;

- lathe;

- ruler;

- welding machine;

- sandpaper.

The manufacturing process of the chisels:

Step one. Chisel blank

First of all, we need to cut a piece for a chisel from a piece of spring. The spring usually goes in an arc to straighten it, we need to heat the spring well in the furnace and leave it to cool gently. After that, the steel should become plastic, the plate can be leveled with a sledgehammer.

Well, then we draw the dimensions of the workpiece on the material and cut it with a grinder. Of course, the steel turned out to be quite thick, so it will take quite a while to cut.

Step Two Trumpet

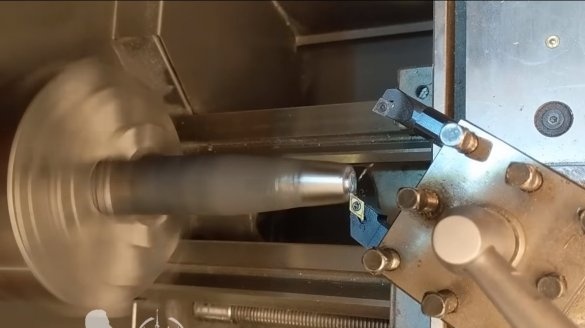

We will need to make a part in the form of a cone from a piece of pipe, a handle will be inserted into this part. The author cut off the desired piece from the old bed leg and polished the pipe to a shine using a lathe.

Next, the pipe needs to be narrowed at the end, for this we heat the pipe and proceed to forging. Gradually, step by step, we turn the pipe into a cone. At the end we grind the pipe, the author also heated and polished the workpiece from the spring to a shine.

At the end, a piece of pipe with a tapered end is processed on a lathe.

Step Three Chisel assembly

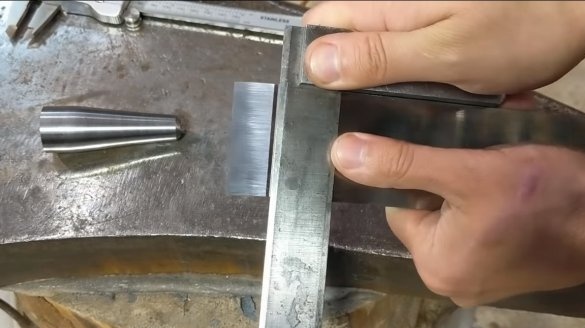

Directly the part that will be a knife should have a narrowing at the end where the handle will be attached.We cut off the excess metal using a grinder and check how smooth the knife turned out using an even metal ruler. If there is curvature, we heat the metal and level it with a hammer.

We weld our cone from the pipe for fastening the handle to the tail of the knife. We clean the welding seam so that the product looks monolithic. The author also formed a bevel on a chisel using a belt sander. That's all, after carefully grinding to a shine, the chisel is ready, it remains to make a handle.

Step Four Pen making

The handle should be as strong as possible, and plywood can be considered the strongest wood material. The author glues pieces of plywood in layers using wood glue. Next, we cut off the excess with a planer and proceed to processing on a lathe.

To give the handle extra strength and make it beautiful, impregnate the handle with liquid to normalize and, after impregnation, send it to a heated furnace to solidify the impregnation.

After normalization, we carefully grind the handle on the lathe to a perfectly smooth state. Now the handle looks chic and very strong, for an additional effect you can cover it with a thin layer of oil for wood.

Step Five Assembly

All parts are ready for assembly, if desired, you can polish the chisel to a mirror shine. Of course, spring steel will actively rust, so do not forget to lubricate the tool during long-term storage.

We install the handle in the chisel, and it is ready. The tool turned out to be chic and very reliable. On this project is completed, I hope you homemade I liked it, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!