Some craftsmen are engaged in casting from fusible alloys and metals, such as tin or lead.

In this article, the author of YouTube channel “TOKARKA” will tell you how he made a miniature electric oven for such purposes.

Homemade is very easy to manufacture, and can be made in home conditions. All materials for manufacturing are available to everyone.

Materials

- Ceramic cup

- Tin Can

- Nichrome wire

- Silicate glue (sodium liquid glass)

- Broken telescopic antenna

- Alabaster.

Instruments, used by the author.

—

—

- Computer power supply

—

- Pliers, wire cutters.

Manufacturing process.

Such a furnace can be made from a pair of stainless steel mugs, but with this design there are problems with the insulation of the heater.

Ceramic or porcelain dishes are best suited as a working container. So it will be easier to choose the size, and they have very high heat resistance - up to 3000 degrees.

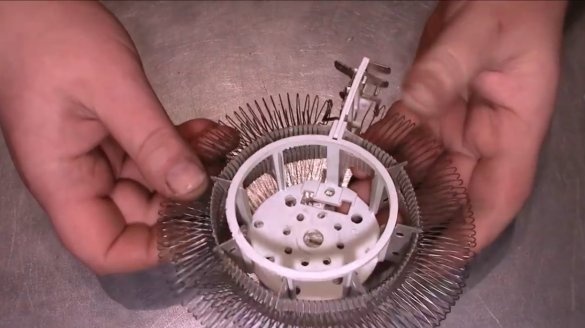

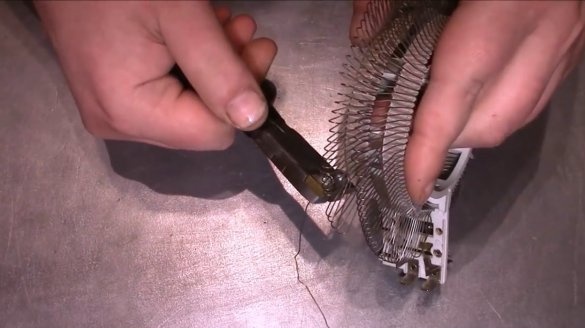

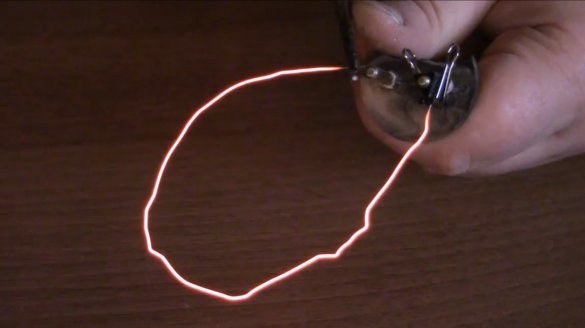

Nichrome wire is suitable for the heating element, it is quite simple to get it.

The author found a broken fan heater, he will use a piece of heating wire from him. Also, a non-working hair dryer is suitable as a donor.

The master will take power for the heater from a computer power supply, with an output of 12 V, and a current of 9 A.

When connecting a piece of wire to a power source, it should have a dark cherry color, as in the second photo. If she will regret stronger, then very quickly fail. You just need to pick up the wire of the required length.

The wire should be aligned.

The master begins to manufacture a working tank. He removes the handle, and aligns the bottom.

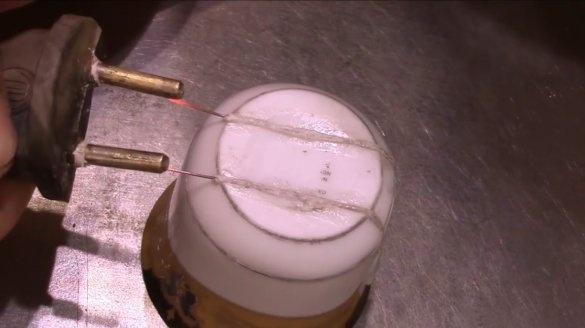

Now makes an annular groove in the lower part of the tank. It will fit the heater.

Two more grooves are made at the bottom of the cup.

Next, you need to fix the heater in the grooves. Silicate glue (aka liquid glass) is suitable for this. This is an extremely cheap material, it is better to purchase it at a hardware store. A kilo of glue costs about 100 rubles. In the stationery store for the same money you will get a bottle of about 100 ml.

So, the wire is smeared with a thick layer of glue, and for quick fixation, you can slightly warm up with a turbo lighter.

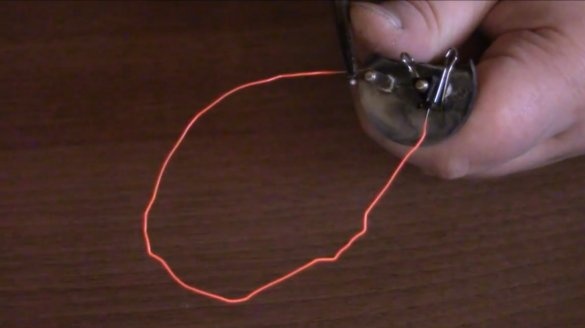

The first inclusion, and check. The spiral functions normally.

Now the master begins to manufacture the outer casing. He decided to use a small tin can. Having tried a cup, he cuts a hole in the bottom.

After such an operation, the cup should sit as tightly as possible in the hole.

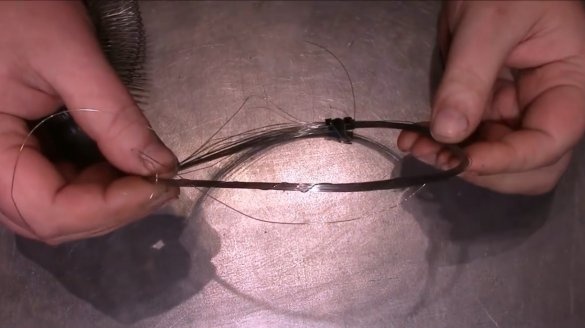

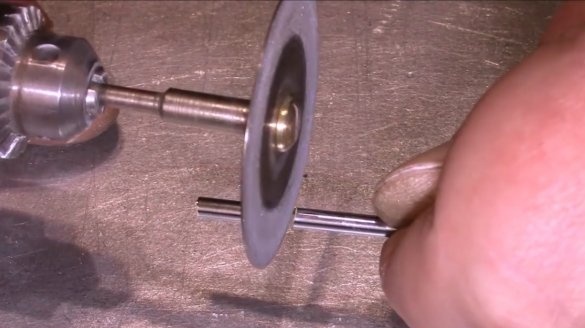

Then two pieces of the tube are cut off from the telescopic antenna. It is put on the junction of the wire with the spiral, and crimped with pliers. It is desirable that the connection point is slightly removed from the tank.

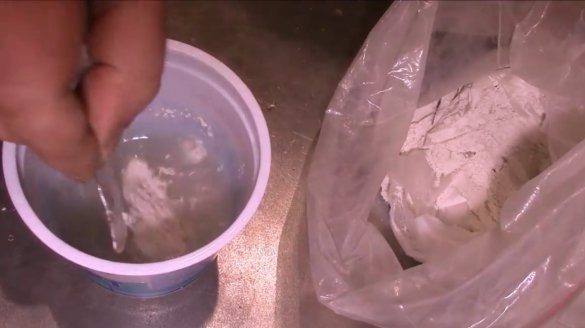

Now you need to mix the grout. It is best to use alabaster, but gypsum is also suitable. When mixing the solution, the author tries to drive as many air bubbles into it as possible, this will improve the thermal insulation properties.

Alabaster sets very quickly, and after 15-20 minutes you can begin to evaporate moisture. To do this, the master connects the heater to the output of the 3 Volt power supply. This process will take several hours.

So, the drying is over, you can connect the operating voltage of 12 V, and melt the lead. The process is very fast, because the power of the stove is just over 100 watts. And this is enough for such a small capacity.

To reduce heat loss, he made just such a cover, filling it with alabaster.

Using, the author measured the temperature inside the stove. She was 465 degrees.

He also applied a layer of silicate glue to the top of the stove. When heated, it foamed, and improved the connection of the cup with the jar.

To improve the appearance, the master cleaned the can of paint. The surface can be coated with heat-resistant paint for barbecue. It is also desirable to make for the stove not only a lid, but also a handle. By increasing the amount of thermal insulation, much higher temperatures can be achieved.

This is how the finished stove looks in comparison with the Chinese factory counterpart.

This one is able to heat up only 15 degrees above the author's. But its cost is several times higher.

Thanks to the author for the simple idea of an electric melting furnace, which is useful in the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.