I welcome all fans to craft, today we will consider how to make a beautiful and strong coffee table made of concrete and walnut. Homemade It looks quite interesting, the concrete mix was used by GFRC, in which fiberglass is added to increase strength. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- concrete mix GFRC;

- boards made of walnut or other wood;

- furniture dowels;

- carpentry glue;

- oil for wood;

- Particleboard.

Tool List:

- screwdriver;

- drill;

- a circular saw;

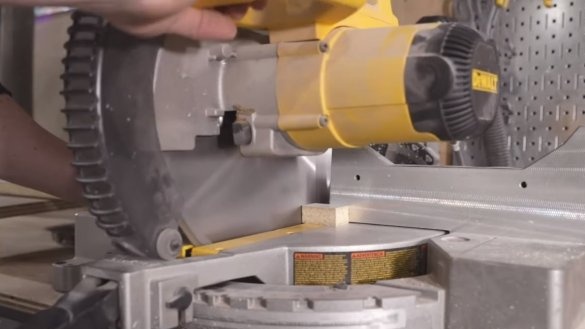

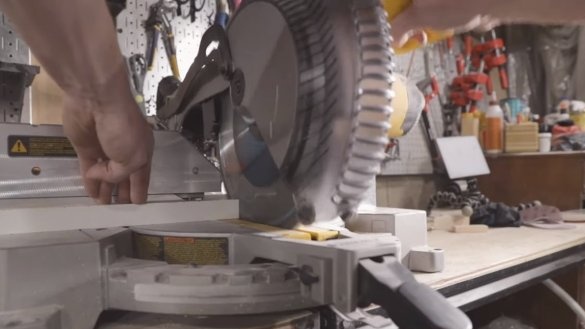

- Miter saw;

- silicone sealant;

- compressor and special spray gun with large capacity;

- milling cutter for drilling holes for dowels;

- Thicknessing machine;

- clamps and more.

Homemade manufacturing process:

Step one. Countertop Making

The manufacture of countertops can be considered the most difficult and responsible task. To begin with, you will need to make a strong formwork, in which concrete will be located. The author used chipboard as material, we mark everything and cut the material. The formwork is assembled using self-tapping screws, after assembly, sealing is to be done. We will need silicone as a sealant, apply it to the joints, and then cut off the excess using a special tool with a ball at the end, as a result, the tabletop will get neat corners.

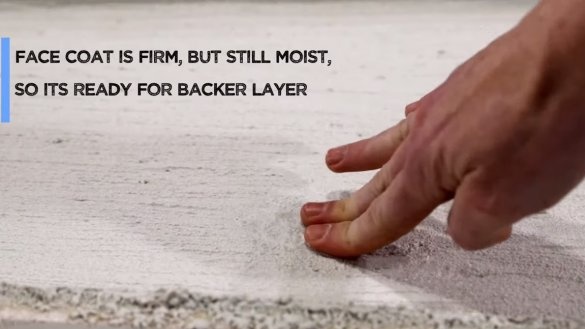

Now we are preparing for the manufacture of countertops, as a reinforcement, you can prepare a grid for construction purposes, we cut it into a piece of the desired length. We also prepare the concrete mixture, the first layer will be front, its author is applied to the formwork using a spray gun. We wait until the first layer is set, and lay the reinforcing mesh.

Next, you need to prepare a power layer of concrete, such concrete will be more dense, fiberglass is added to it. We put concrete into the formwork, spread it with our hands and carefully level it. To make the planes smooth, we press concrete on top with sheets of chipboard.

Step Two Worktop refinement

When the concrete hardens without dismantling the formwork, we cut off the excess concrete with a grinder, and also perform rough grinding. Then, we carefully disassemble the formwork so that the formwork can be removed easily, it is advisable to process it with a separating wax or a similar substance before pouring concrete.

Having removed the formwork and removed the countertop, we grind its front side with an emery cloth to an ideally smooth state, but in the end the concrete can be polished.

Step Three Walnut pedestal

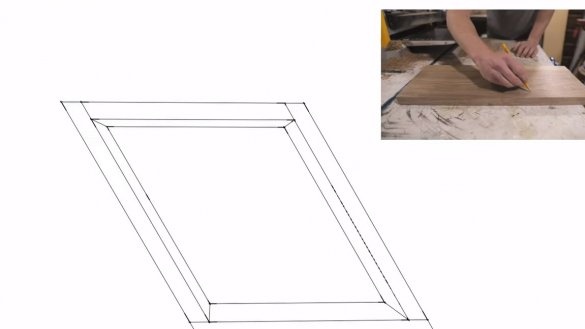

We make a support from walnut, for this we need even boards of the same thickness, it is desirable that the wood species is strong. The author drove the boards through the thicknesser to get the material of the same thickness. Then the boards are well sanded with any suitable tool and cut at the right angles with a circular saw. As a result, we should get a parallelogram, we collect it on furniture dowels and carpentry glue.

When the glue hardens, we carefully grind everything and polish it with an orbital machine to a perfectly smooth state. At the end, we impregnate the tree with oil, if the wood was well polished, the tree will look very beautiful.

Step Four Assembly

We assemble the table, fasten the support with dowels and screws to the concrete countertop. For additional reliability, you can use thick glue or something similar that will not allow the connection to break out over time.

That's all, after that the table will be completely ready, everything looks interesting, in a modern way and from modern materials. This is the end of the project, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!