In the manufacture of this lampshade, invented by Instructables under the nickname nerdyKat, almost everything comes from DVD boxes: both hard plastic and the film that presses the label, and from one box even a round part with a lock holding the disc. To homemade and you turned out as accurate as the master’s, in addition to straight arms, you’ll also need template.

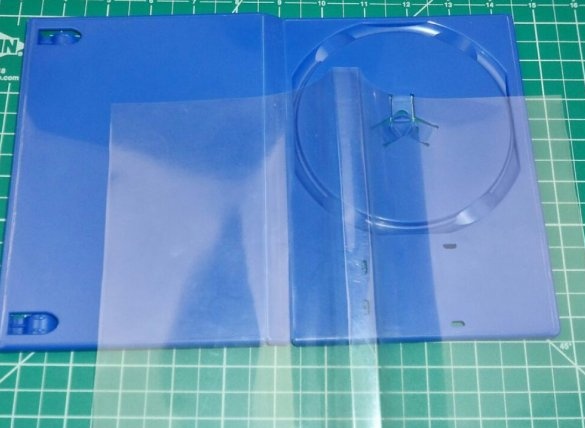

The master separates the film from the boxes and puts it back - it will be needed later:

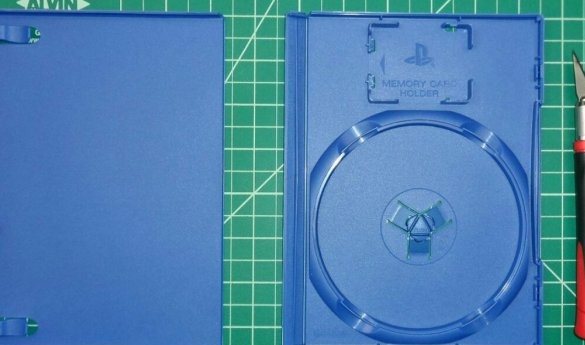

It divides the boxes into two parts:

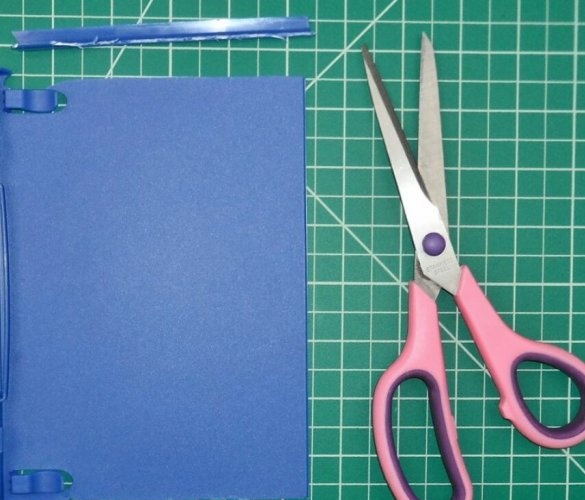

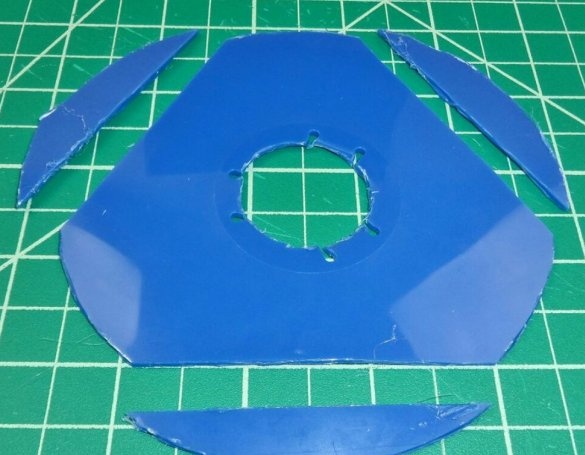

And it separates the ends, which would otherwise interfere with the cutting of strips:

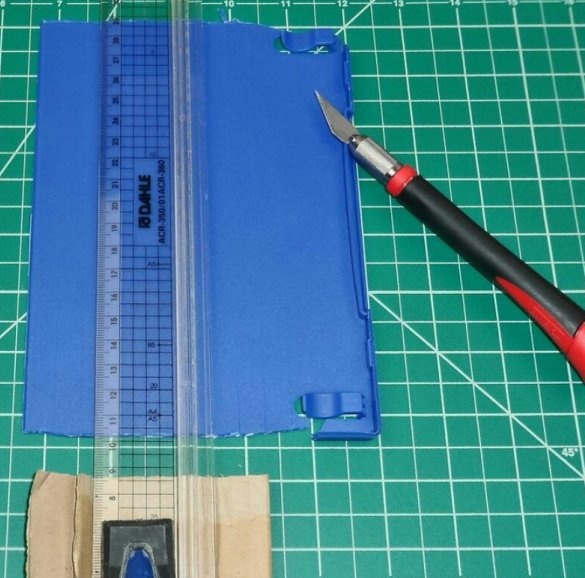

Marks the workpiece for cutting strips - draws parallel lines every 10 mm:

He tries to cut the sheet into strips with an electric burner - modern, with a set of nozzles, but it turns out very slowly:

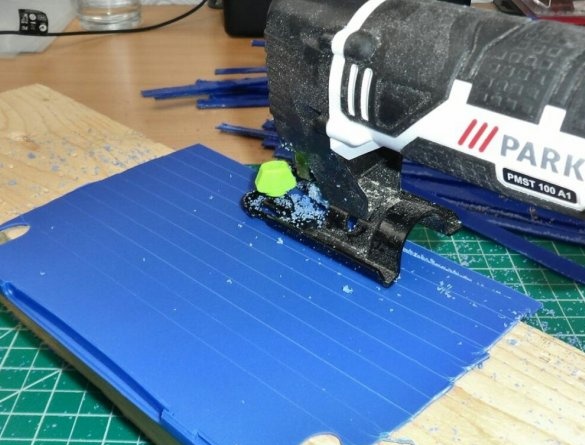

Therefore, the master takes on a jigsaw, if you type in Yandex its name, it turns out that this is a special jigsaw for modellers:

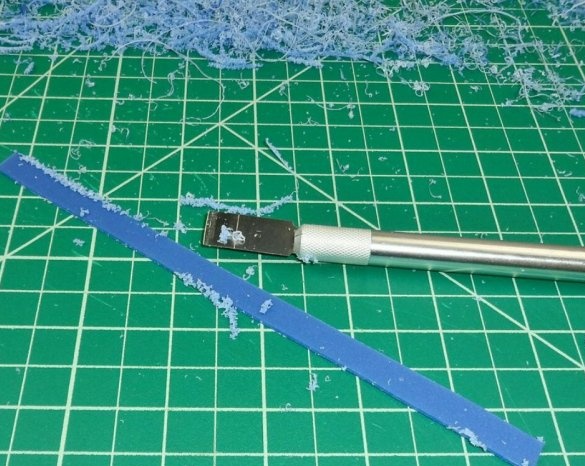

Deburrs with a knife with interchangeable nozzles in two steps, first applying nozzle No. 18, then No. 11:

From the same plastic, it cuts out a kind of welding additive:

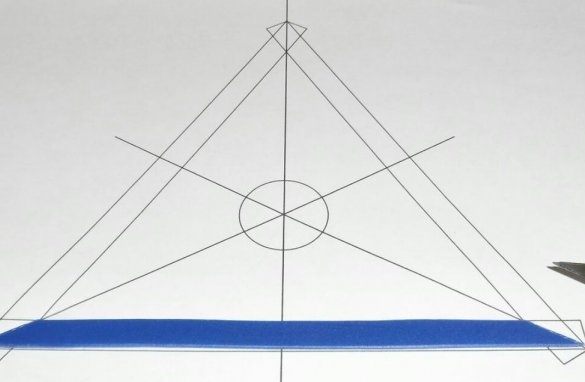

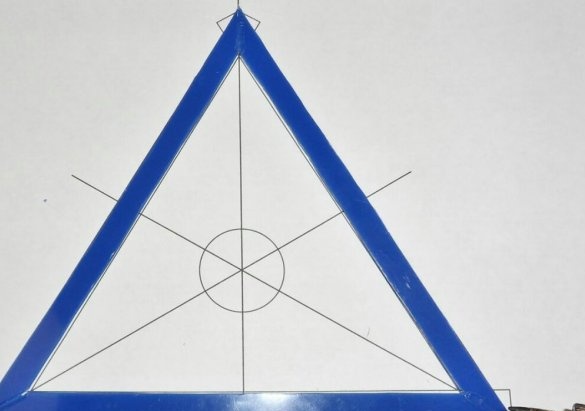

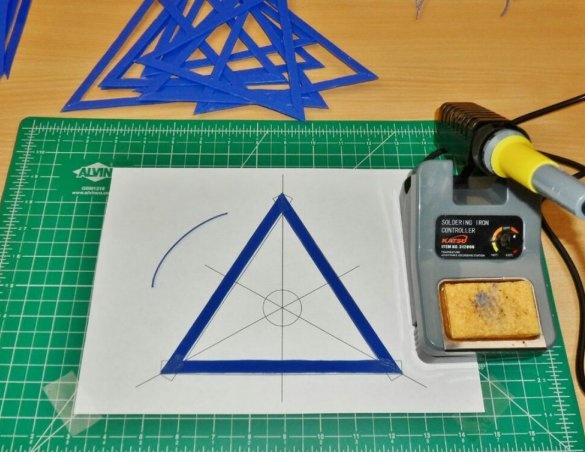

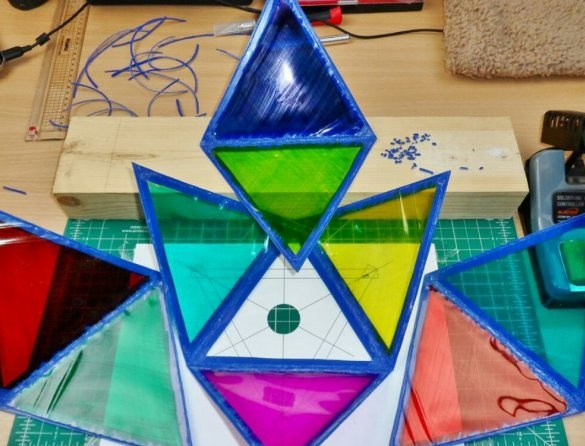

Makes parts for triangles according to the template:

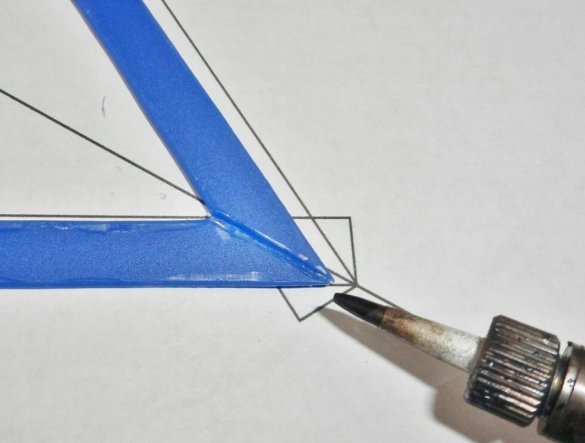

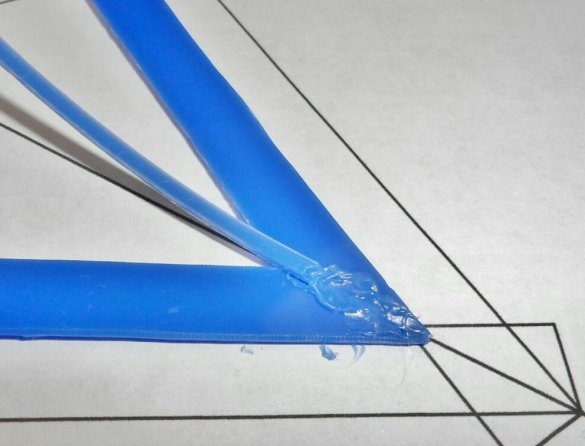

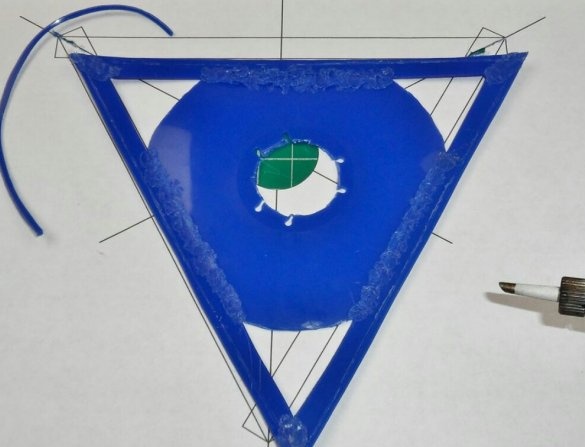

Using the same template, he welds triangles of these parts with a soldering iron, not forgetting to add a semblance of additive and use good ventilation:

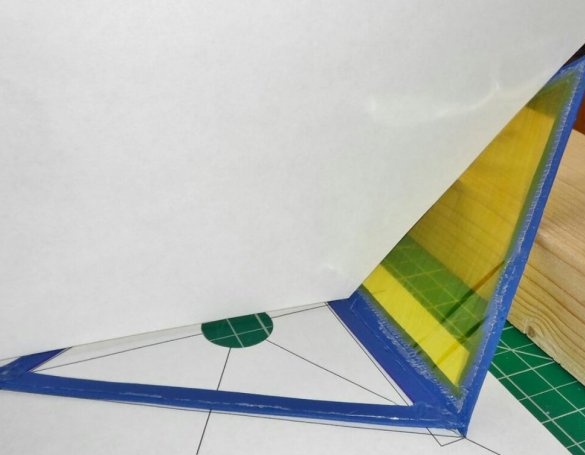

An electric burner with a nozzle in the form of a knife welds the film to 18 out of 20 triangles, while simultaneously cutting it into size. He leaves two more triangles without a film: one for access to the lamp holder, and the second for further see why. The lamp takes without fail LED. The film from the same boxes was only enough for 12 triangles, for the rest the master takes a transparent bag.

Stains the film (this step is optional):

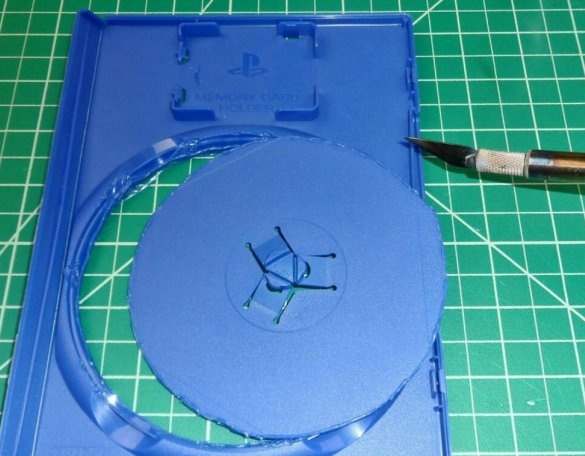

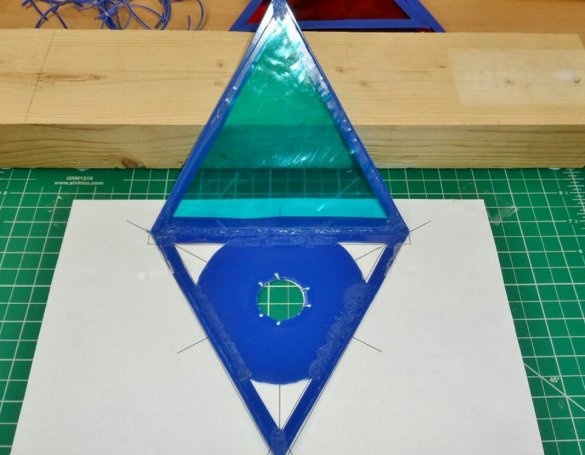

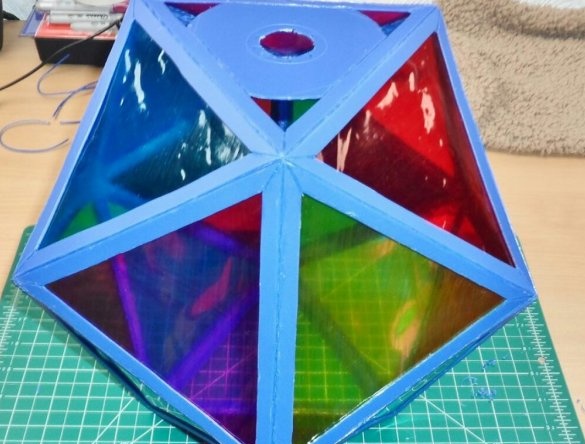

After a little refinement, a box part designed to hold the disk is welded into one of the two triangles not tightened by the film, now it will hold the lamp holder:

An angle of 138.19 degrees between triangles is not easy to obtain if there is only a square piece of plywood. But taking the same template and then leaning and tilting the square as shown in the next photo, the master gets exactly this angle:

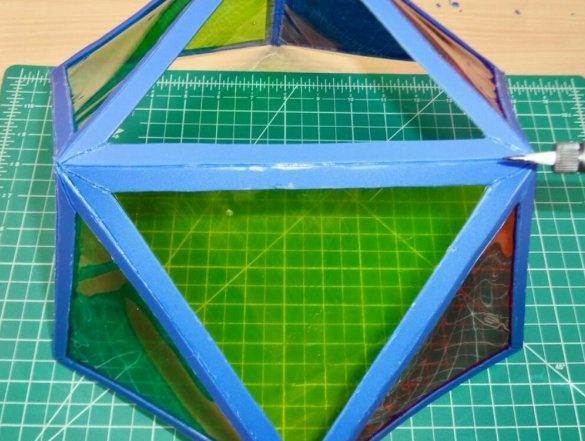

Gradually collects the first double triangles, and then from them - two halves of the ceiling:

And finally, it combines them into a whole ceiling:

The following shows the result of the work, which, according to the master, took as long as ten hours - a finished lamp, and also shows where exactly the triangle should be located, not covered by a film to access the lamp holder:

It is clearly noticeable that the lamp is screwed in LED, I recall once again that the other is not suitable for this homemade product.