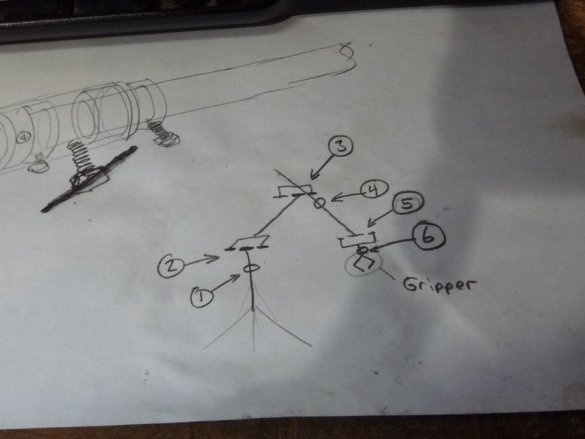

Master called it device “Production assistant.” For the manufacture of anything? Anything. If in simple terms, it’s a stand with a suspension. You can fix any part or workpiece on it, for further processing or just to look at it from the side and understand in which direction to move on.

The basic requirements for this product are as follows:

- Be able to withstand loads of up to 5 kg

- Suspension at least 60 cm from the rack

-Mobility

-Lack of electrical parts, only mechanics

-Street placement

Tools and materials:

-Welding machine;

-USHM;

- Protective glasses;

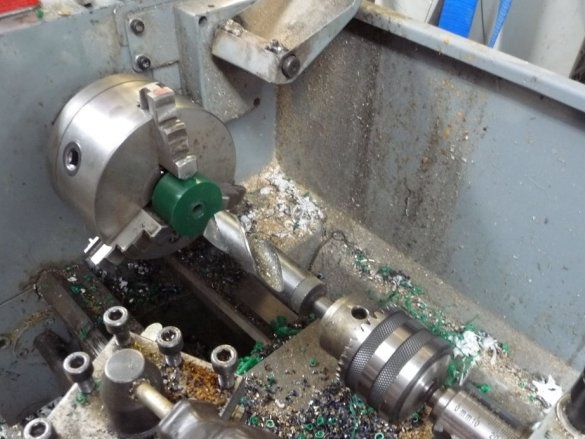

-Lathe;

-Pipes of different diameters;

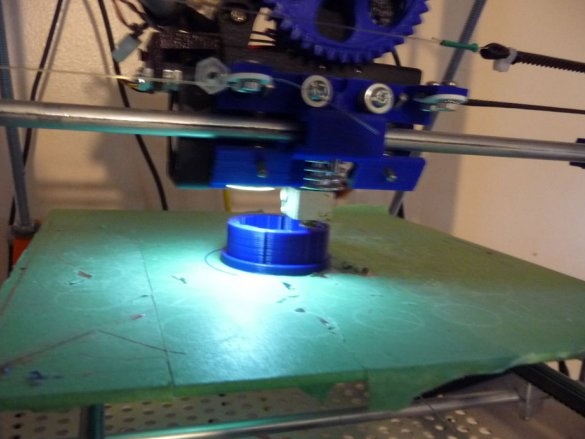

-3D printer;

-Door hinges;

-Fasteners;

-Paint;

-Metal corner;

-Threaded rod;

-Nuts;

-Drill;

Step One: Prop

The master welds three door hinges as a starting point. A corner is welded to each half of the loop. Corners play the role of legs and are movable with loops. Thus, you can install the device on an uneven surface. A metal pipe is welded in the center of the triangle.

Step Two: Retainers

To fix the legs and some other parts, the master makes clamps. A steel bar is welded to the head of the bolt. A hole is drilled in the face of the nut. It cuts the thread as on a winch.

Then the tube and the rod are taken. The rod should go into the tube and the tube into the nut. A hole is drilled in the tube. From one end of the tube and the rod is welded on a bolt. A nut is put on the tube. Bolts at the edges are inserted into the eyes welded, one to the corner, the second to the pipe. Now you need to adjust the required angle and tighten the knob.

Step Three: Arrow

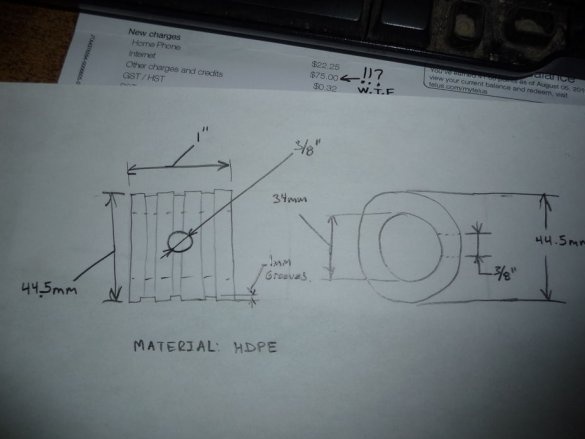

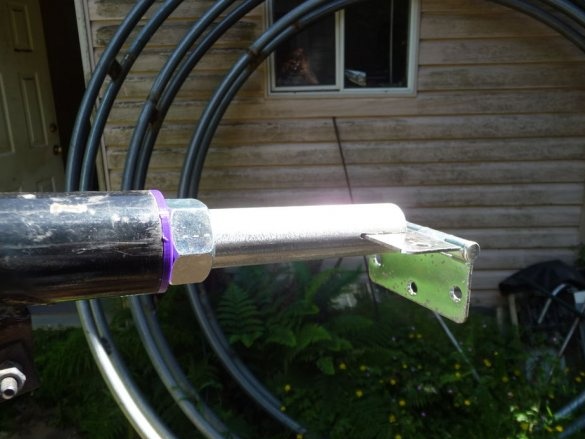

The part mounted on the "third hand" should be able to rotate around the rack. The master makes an arrow that will rotate in various directions. He picks up the pipe so that it can be installed in the welded rack. The printer prints bushings. One sleeve is manufactured on a lathe. Then it welds the tube to the shelf of the corner. Along the corner welds another tube. Installs bushings.The rotary part is ready, it remains to install it on the rack.

Makes and installs a two-segment sleeve on the rotary part. The sleeve allows you to adjust the tilt of the boom of the device up and down.

Makes fastening and sets the middle part of the boom. This part has the ability to move forward and rotate along the axis.

Step Four: Suspension

The master made two suspensions, one from a corner, the second from a cylindrical part. Depending on the task, you can change the suspension.

Step Five: Painting

Now it remains only to paint the “third hand” and wait until it dries.