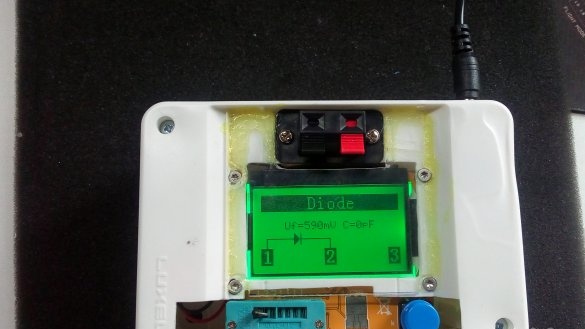

Good day to all! I somehow got myself a tester for electronic components at a famous Chinese site.

However, there were a couple of problems:

- The device was powered by a crown battery (9V)

- The board and display of the device were not protected by the case

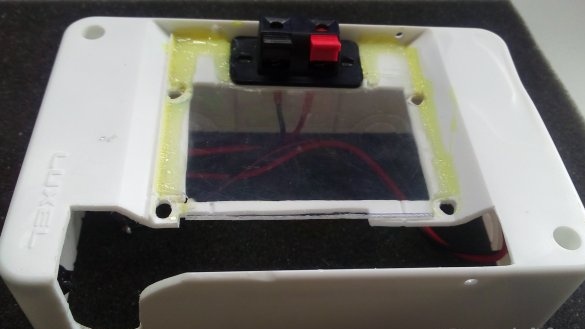

It was decided to make a case for the device and get away from power by means of a crown (they cost not at all cheaply).

Materials and tools:

- External boxing for automatic machines / modules for 2 devices (1 pc)

- Spring-loaded acoustic terminal (1 pc.)

- DC power connector with terminal block (1 pc)

- Car sealant in a tube (1 pc)

- Clay moment crystal

- Acoustic wire (cross-section 2x0.5mm square. 30cm)

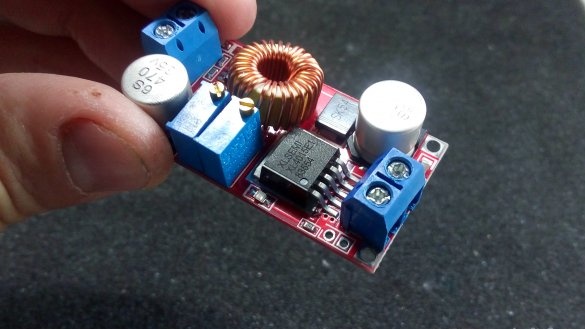

- DC - DC step-down module with voltage regulation (1 pc.)

- Plastic box from a CD disc or a piece of thin plexiglass (size 10x10cm)

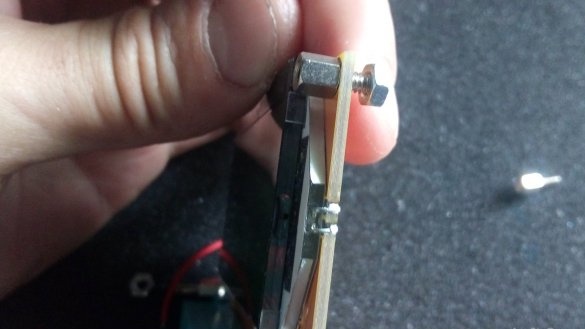

- Stands for motherboards and nuts

- heat shrink tubes

- 4 screws (selected empirically for m3 or m4 racks)

- soldering iron, multimeter, screwdriver, screwdriver / drill, file or file with a small pitch, drills.

So let's get started.

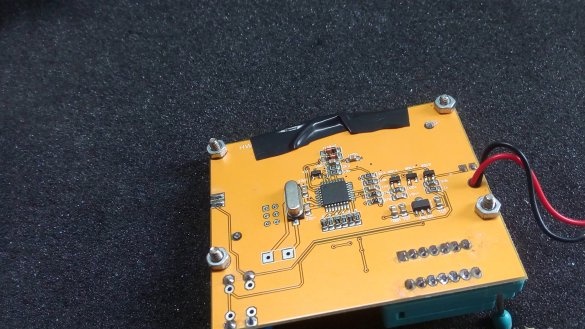

step 1. Cut off the connector for connecting the crown.

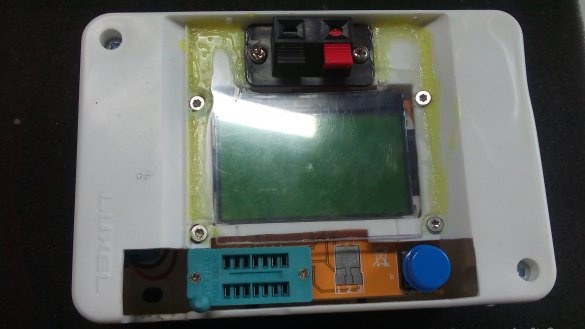

step 2. We fasten the rack device to the circuit board and fix the nuts.

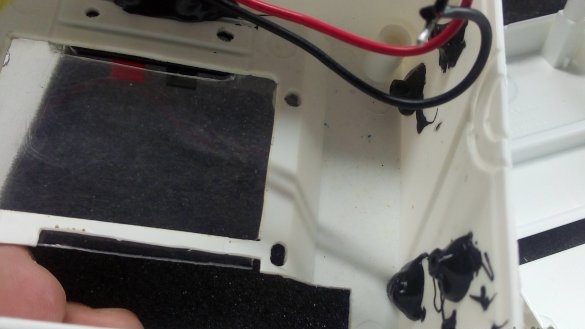

step 3. We disassemble the case and cut out the place for the display, pads, buttons and make holes for the screws to secure the board, cut out a piece of glass and glue it on top to protect the display.

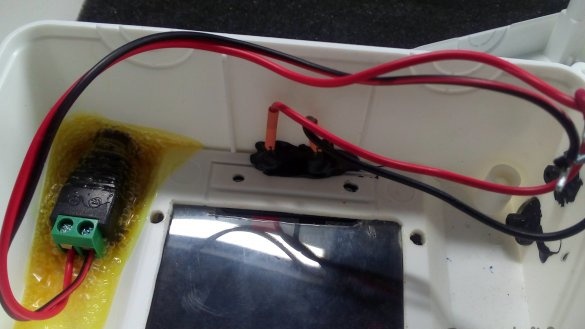

step 4. We drill a hole with a diameter of 8 mm for the power connector and acoustic pads. we fix the block with screws and nuts m3, fill the power connector with glue.

step 5. Soldering wires. Cut the heat shrink to size + a margin of 1 cm on the legs of the acoustic block, put on the wire and solder according to the color of the terminals (Red - red, black - black), then heat shrink and cut off another piece of wire to connect to the power connector (in the center +, around -) , tin and tighten in the connector. We expose the power connector and fill it with glue or car sealant. Then we solder the ends of the wires going from the power connector and the pads (red - red, black - black).

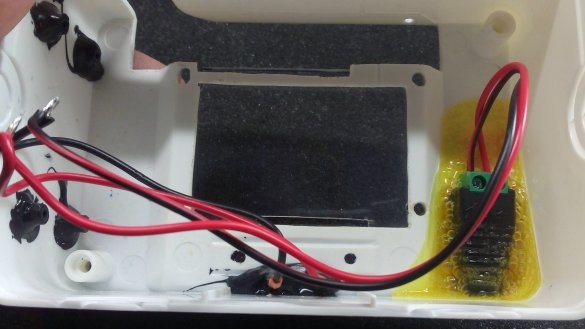

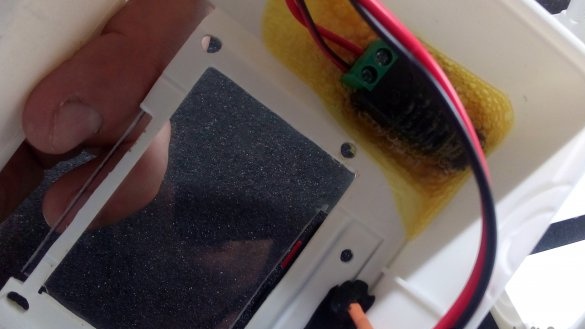

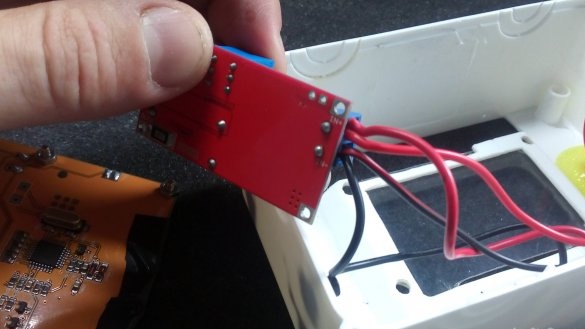

step 6. module fixation. We cut legs from any old technique for self-tapping screws, or we cut the rod from the gel pen into equal pieces. and fasten to the side wall of the housing with glue or sealant, make sure that the mounting holes on the module board coincide with these legs.

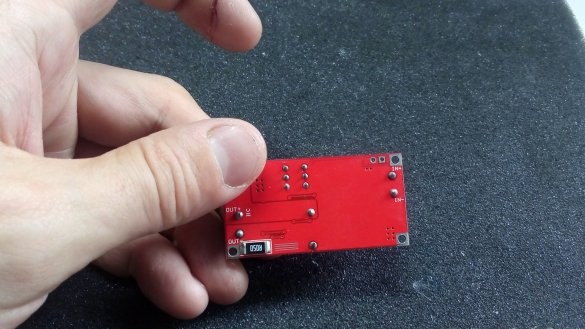

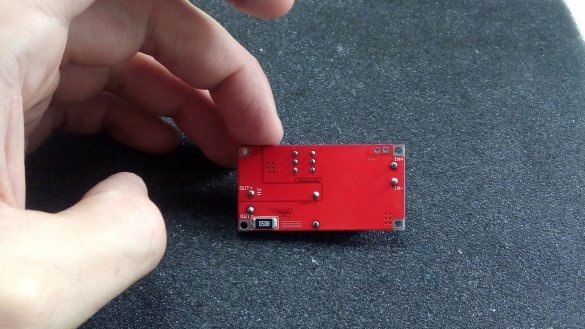

step 7. Module setup. If the crown power is 9 volts, respectively, and at the output from the module should be 9 volts. And where is the module input, and where is the output ????? Everything is simple here. There are signatures under the terminals on the back of the module.IN + means incoming plus, IN- means incoming minus. OUT + and OUT- outgoing plus and minus, respectively. Having fixed the module, we connect soldered wires from the power connector and pads to the IN + connector red, the IN- connector is black.

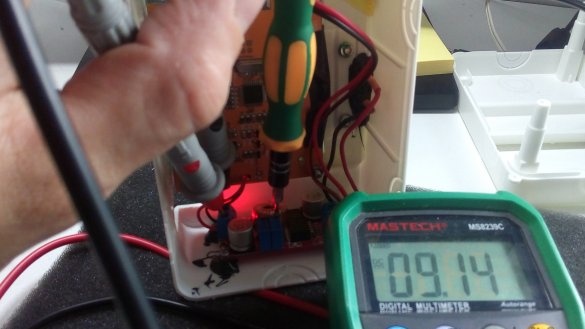

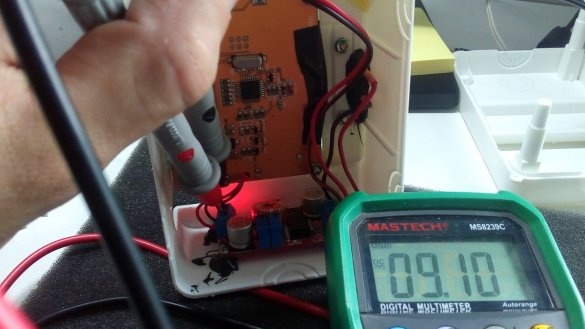

step 8. Setting the output voltage of the module. Here you will need a multimeter and a power source, for me this source was a Chinese 12V power supply connected to the power connector. After connecting, we take a multimeter and set it to the DC voltage test mode. We install the probes on the outputs OUT + (Red probe) and OUT- (Black probe) and with a thin screwdriver we begin to turn the potentiometer until we see the 9c we need on the multimeter display. This completes the configuration of the module.

step 9. Device connection. We disconnect the power source and take the wires from our component tester and connect to the terminals of the terminals of the OUT + (Red) OUT- (Black) step-down module. and fix the module on the prepared legs with small screws.

step 10. Assembly and inspection. We select the wires, check the reliable fastening of the wires in the terminals, assemble the case and connect the power source and check. Now you can take the device with you and not worry that it will break or crack, you can still buy or take a suitable power supply, especially since they cost a little more than the crown, and their resource is higher. Good luck to everyone, health and goodness! Do not judge strictly, this is my first post.