I welcome all fans to craft, today we will consider how to make a drill guide that will allow you to verify holes at right angles. Homemade made of plywood, and the author made the guides of steel pipes so that the weight of the nozzle was not too large. Thanks to this device, it will also be possible to confidently drill holes of large diameters using crowns. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- steel rods;

- plywood;

- threaded rods and nuts;

- carpentry glue;

- self-tapping screws;

- epoxy adhesive;

- two springs.

Tool List:

- circular or jigsaw;

- disk grinder;

- drill;

- drilling machine;

- Bulgarian.

Homemade manufacturing process:

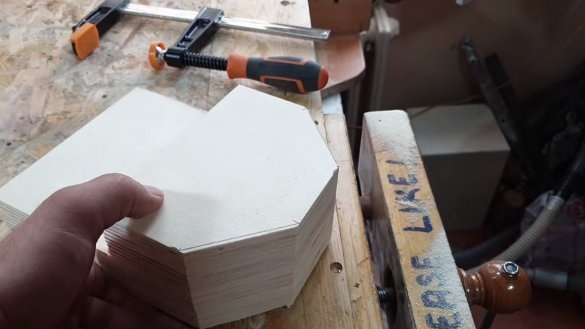

Step one. Cut the details

First, we cut all the necessary details. If you look at device, you can take 3 parts that are identical in shape, they have the shape of a horseshoe. We cut out these three parts so that they turn out to be the same, they can be glued together with double-sided tape and sanded all together.

After that, we immediately outline the places for the holes and drill them at right angles to the drilling machine. These holes will be needed so that tubes that are guides can be installed.

In the end, do not forget to cut out the base, one of the "horseshoes" made earlier can be glued to it with carpentry glue.

Step Two Central unit

We make the central block, which will move on the guides. A drill will be clamped in the central unit, and it is for her that we must make a clamp. We drill a hole with a crown along the diameter of the front of the drill, to which the handle is attached. Depending on the shape of the drill body, we modify the clamp with files.

The clamp will be pulled together with the help of threaded rods and nuts, the threaded rods are wrapped in plywood with epoxy glue.So that the clamp can be untwisted and get a drill, the author uses the “wing nuts”.

In the end, you will need to make and install linear bearings in the moving block, this is a kind of bushings. Such bushings can be made on a lathe; each bush is made of round timber through which holes are drilled. You can also use ready-made steel linear bearings, which are sold in China. Glue linear bearings with good glue and fix with self-tapping screws.

At the end of the step, as an additional emphasis for the drill, the author glued and screwed a triangular piece of plywood with screws.

Step Three Assembly

We assemble the structure, first we install steel tubes in the base, the tubes are fastened with screws or screws through the holes in the base. Next, you can install the middle movable platform, and after it we attach the upper platform. The tubes at the bottom and top are securely fastened to the glue and screws so that nothing is skewed.

After making sure that the central unit moves easily and does not wedge anything, you can put the springs. First, the author put one spring in the center, but it was not enough, as a result, it was decided to put two springs on the sides, which began to lift the platform already with uniform and great effort. We fix the springs with self-tapping screws with washers.

Step Four Final touches and tests

The homemade product is almost ready, in the end, at the base, you need to drill a hole of large diameter. We install a drill in the clamp and, using a large-diameter crown, drill the base.

We also fasten the handle of wood to the base, by which it will be possible to firmly hold the car. And so that the drill does not fall down, the author made a latch of wire.

That's all, after this homemade product will be ready, you can experience it. The author easily drills holes at right angles in the board, and with such a machine you can conveniently and safely work with large-diameter crowns. With a homemade product, you can conveniently drill a hole at a right angle in a wall, ceiling, floor or any other plane. On this project can be considered successfully completed. I hope you enjoyed the homemade work and found useful thoughts, good luck and creative inspiration for yourself if you decide to repeat this. Do not forget to share your ideas and homemade things with us!