Hello dear readers andthe inhabitants of our site!

Maybe you want to make a relief wall, maybe decorate a personal bar - in fact, there are a lot of areas where you can apply block masonry. But it costs a lot of money.

In this article, the author of the YouTube channel “DIY Creators” offers you a method of self-production of stone blocks.

Materials

—

—

—

- Cement, sand.

Instruments, used by the author.

—

- nozzle mixer

- Spatula, trowel

- Respirator, gloves.

Manufacturing process.

Everything is very simple: you need a bag of cement, several molds, a respiratory mask and a pair of mittens.

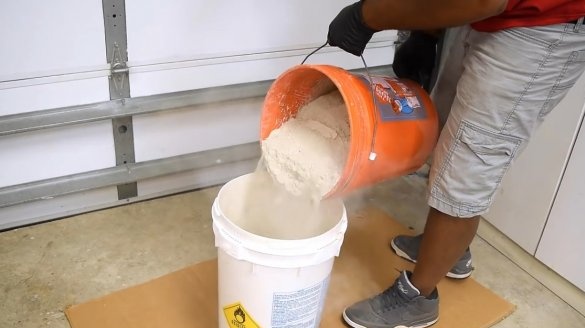

The cement mixture pours out into a large plastic bucket.

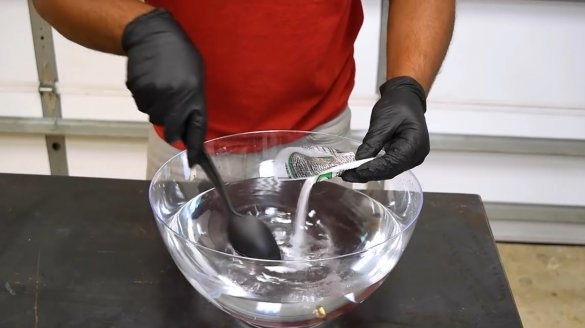

To speed up the whole process a little, the author starts a special powder (hardener) in a separate glass container that accelerates the hardening of cement. Within an hour, the solution should solidify.

After getting into the water, the mixture quickly begins to solidify, so it should be continuously and actively mixed. Then the liquid is poured in a uniform stream into the cement powder and thoroughly mixed. Since the entire packet of cement will be kneaded, at least 5 liters of water will be required.

Next, you need a powerful drill with a special nozzle for mixing. The solution is thoroughly mixed

The author makes the first test casting to feel how the solution will behave.

The back surface of the form should be tried to level as much as possible.

There is another way to improve the shape - this is a little shake it to allow air bubbles to pop up to the surface.

While the forms are standing, the author continues to work on the second part of the batch. He adds a black colorizer to the mixing tank. For these purposes, you can use regular mascara, or black gouache.

The following three forms are filled with a raster of a darker shade. By the time the author puts the final batch of kneading into the mold, the activity of the setting controller is already reduced and the solution is slowly starting to solidify.

Usually, under the influence of a chemical reaction, during curing, the mass begins to warm up. Therefore, it is desirable to moisten the surface for at least 30-40 minutes.

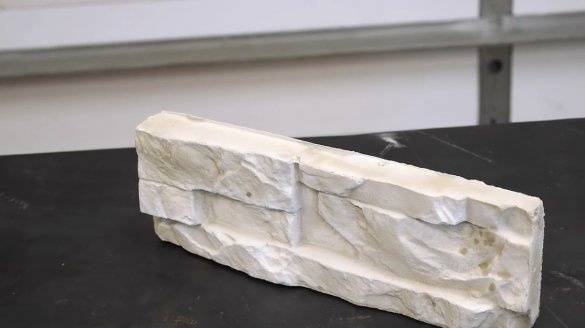

Despite the relief of the form, and the tight fit of the cement mass, hardened cement quite easily lags behind the form.

And look at the result - they are great!

Thanks to the author for a simple but very interesting idea!

All good mood, good luck, and interesting ideas!

Author video can be found here.