The master has long been interested in aircraft models. At first it was a model of aircraft, then quadrocopters. In this article, the wizard will tell you what materials it is better to choose for a quadrocopter, as well as how to make a frame from plywood. Let's watch a short demo video.

To make a quadrocopter, the master used the following

Tools and materials:

-Birch plywood;

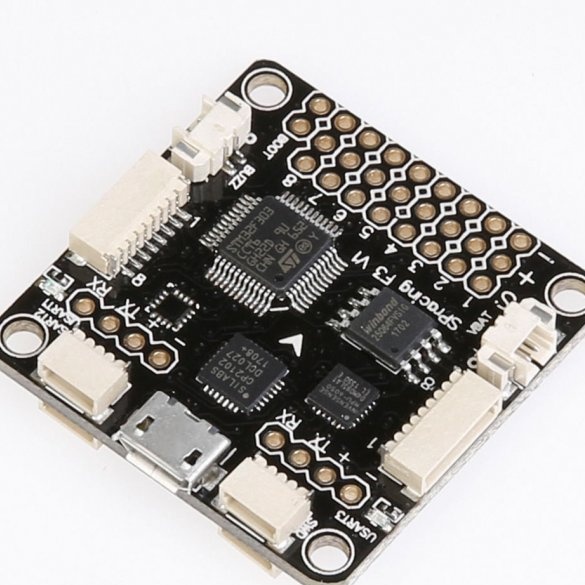

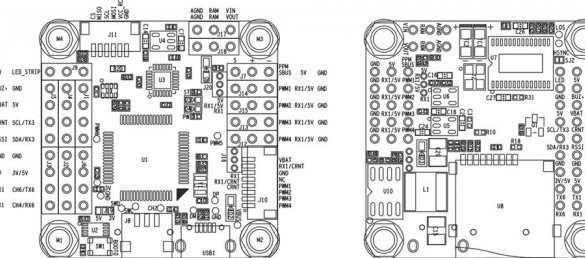

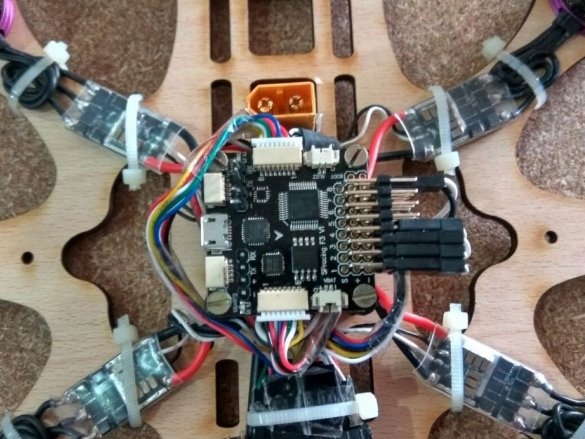

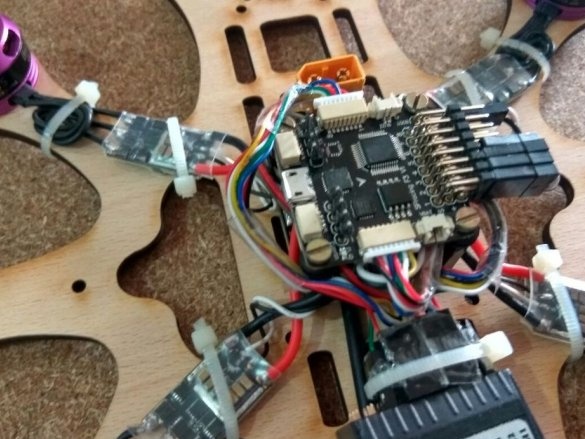

-Omnibus F4 controller, SP Racing F3;

-Mateck power distribution board;

- Controller HGLRC 28A BLHeli ESC - 4 pcs;

- Motor Racestar BR2204 2600Kv Racing Edition -4 pcs;

- Propellers KingKong 5X4X3 - 4 pcs;

- Flsky TH9X radio module with receiver;

Battery Gens 3800 mAh;

-Racks; - 16 pcs;

-Screws M3;

-Screwdriver;

-Soldering accessories;

-Knife;

- CNC cutter;

Step One: Material Selection

Frame.

Usually the frame is made of light and rigid components, such as fiberglass, carbon fiber, wood, aluminum, etc. There are many different types of frames, the master will make a frame for four engines.

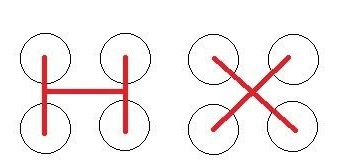

Such frames are mainly in the H-form or X-form. The X-shape is a good balance between stability and maneuverability. It is this frame that the master will make.

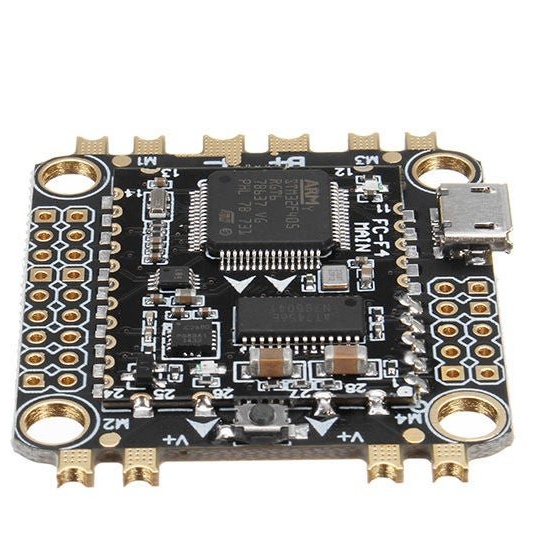

Controller.

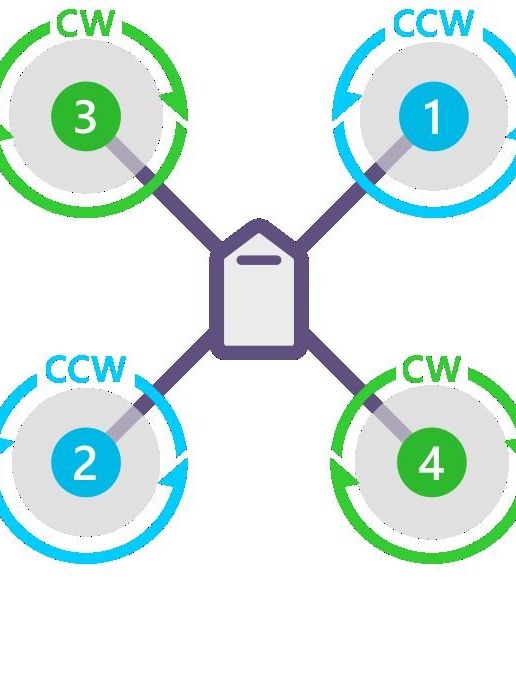

The controller controls the operation of the engines. The diagram shows that all engines rotate in opposite directions to neutralize the torque generated by each engine. The controller is the brain of a quadrocopter, it is basically a small computer that uses its sensors to constantly measure angle and speed.

Flight controllers are mainly classified according to processor specifications.

Engines

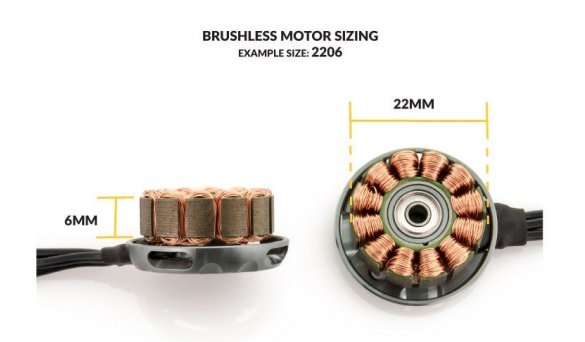

There are two types of motors, brushless motors and brushless motors. Most quadrocopters use brushless motors that can respond very quickly to changes in speed and torque requirements. For brushless motors, special electronic speed controller (ESC).

The size of brushless motors is indicated by a 4-digit number - AABB. “AA” is the stator width, and “BB” is the stator height or stator diameter, both in mm (millimeters). For example, the Racestar BR2205 has a stator with a diameter of about 22 mm and a height of about 05 mm.

In fact, the higher the stator, the greater the power at higher speeds, and the wider the stator, the greater the torque at lower speeds.

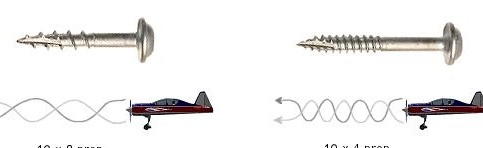

The KV value of the motor indicates the speed at which the motor will rotate when you apply 1 volt to its windings.It is determined by the number of windings of the copper wire in the motor stator and the magnetic force of the magnets.

Fewer windings mean less resistance, and therefore higher rpm. This is why engines with higher KV tend to have less stator winding.

KV determines which screw you can use with the engine. The lower the KV, the larger the screw it can rotate, and vice versa. It is not possible to increase the lifting force by installing a larger screw on the engine with a higher KV, since the torque requirements will go beyond the permissible power and the engine will overheat.

For example: BR2205 2600 kV motors can work with 5x4 inch screws, and BR2212 1000 kV motors can work with 10x4.5 inch screws

KV is by no means an indicator of engine power output; engines with a higher KV are not necessarily more powerful than engines with a lower KV.

Electronic speed controllers (ESC).

Recent advances in mini quadrocopters have been made possible by the advent of small electronic speed controllers that allow brushless motors to work. The operation of electronic speed controllers is to receive the throttle signal from the flight controller and maintain the engine rotation at the required speed.

A number of technologies work inside these small devices that are beyond the scope of this manual. When purchasing, choose an ESC with a rated direct current of at least 20% more than the calculated one.

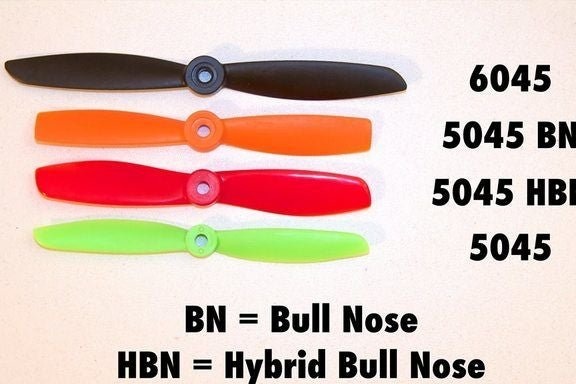

Propellers.

Propellers convert the mechanical energy of engines into traction. The size and shape of the propeller play a huge role in flight efficiency.

There are 2 types of formats that manufacturers use: L x P x B | LLPP x B. Where, L is the length, P is the pitch, B is the number of blades.

Propellers can be made of various materials, such as plastic composite, carbon fiber, wood, etc. Each type of material has unique characteristics, for example, carbon fiber and wood are really rigid and known for their smooth operation, and some plastics are extremely durable. Most of the screws used in mini quadrocopters are made of plastic composites.

The size of the propeller you can use is limited by the size of your frame, as well as the HF power of your engine. As a rule, the more propeller you can use to create a certain thrust, the more effective it will be. For mini quadrocopters, they vary between 5-6 inch screws in 4-5 inch increments.

The number of blades affects traction and energy consumption. The more blades, the more traction and the more energy is wasted.

Batteries

Currently, most drones use lithium polymer batteries, commonly known as Lipo batteries. The battery together with the ESC and the engine is a quadrocopter power system.

Do not think of the battery as a reservoir of energy, motors can pull a monstrous amount of amperes in very short intervals. LiPo batteries are a set of cells, each of which has a nominal voltage of 3.7 V. If a higher voltage is required, these cells can be connected in series to form one battery. Batteries connected in series are marked with the letter “S” and in parallel with the letter “P”.

The more cells connected in series, the higher the voltage and the more cells in parallel, the higher the capacitance.

For instance:

1S = 1 cell = 3.7 V

2S = 2 cells = 7.4 V

3S = 3 cells = 11.1 V

4S = 4 cells = 14.8 V

5S = 5 cells = 18.5 V

6S = 6 cells = 22.2 V

Capacity is indicated in milliamperes or “mAh”. This is the number of amperes a battery can deliver in one hour. For example, a 3S 2000 mAh battery can provide 2 A for 1 hour. so if your quadcopter pulls 20A, then its flight will continue for 2/20 * 60min = 6 minutes.

Nominal discharge indicates the maximum speed at which you can draw current from the battery. It is indicated by the number "C" on top. The higher the rating C, the greater the amount of current the battery can give.

For example, a 2000 mAh 25C battery can deliver up to 2000x25 = 50,000 mA or 50 A.

Step two: design and assembly of the frame

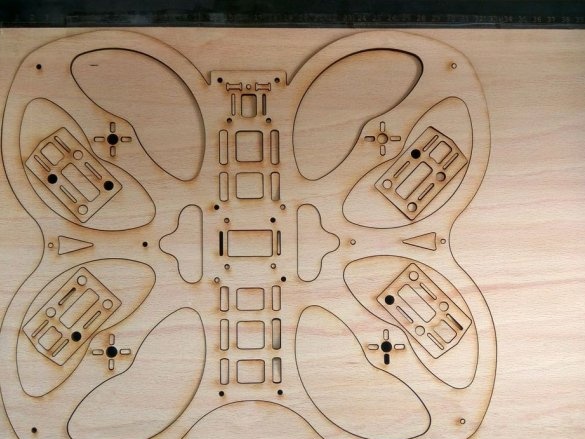

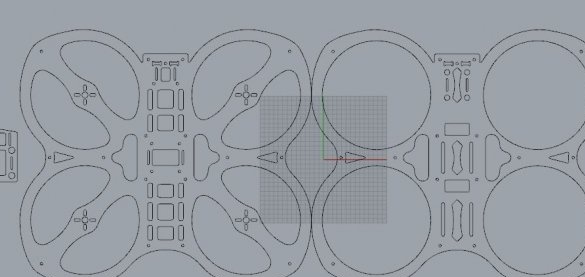

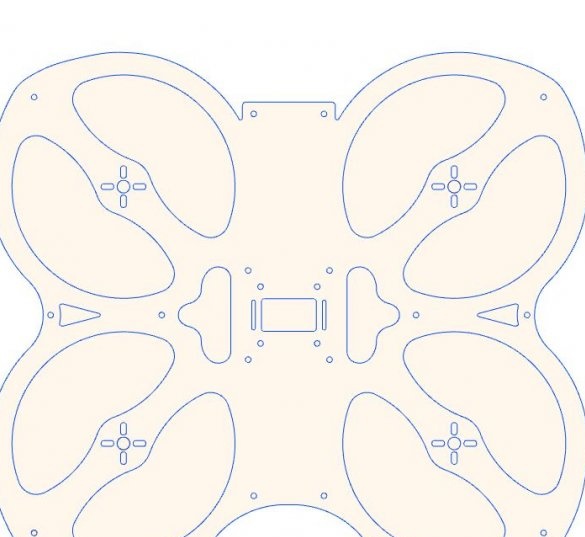

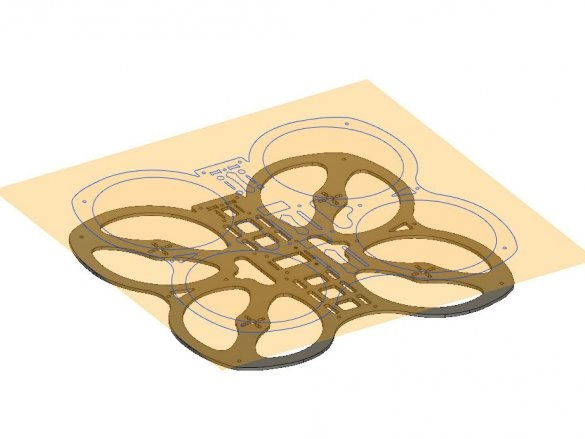

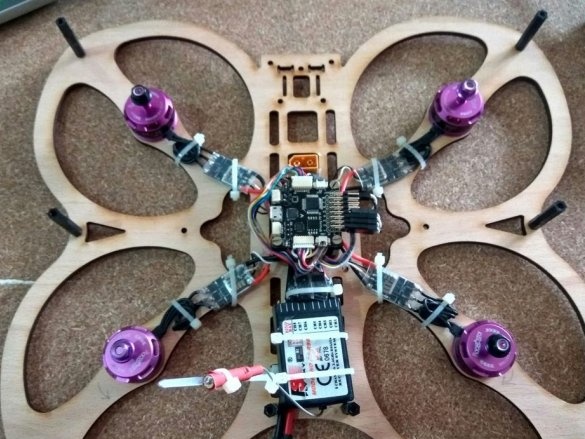

The frame design was inspired by the monarch butterfly shape.When you look at the frame from above, it looks like two wings.

The wizard drew the design in Fusion 360 and Rhino CAD. The frame size is about 230 mm, it is due to the diagonal distance from one engine hub to another. The most popular frame sizes are 210 mm, 250 mm, etc. Once you have set the frame size, draw engine mounts.

The central building is the place where all the electronics will be installed, including the flight controller, receiver, battery, etc. At the midpoint there are 4 M3 holes at a distance of 30.5 mm from each other.

The item is made using laser cutting. If you don’t have a cutter, you can cut in the workshop. The file for cutting can be downloaded below.

File Design.rar

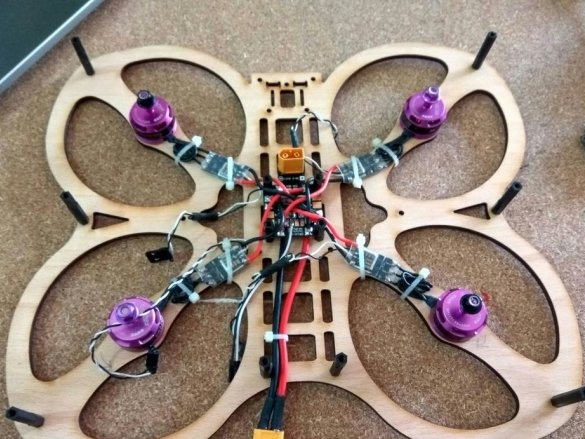

Step Three: Build

Now you need to assemble a quadrocopter.

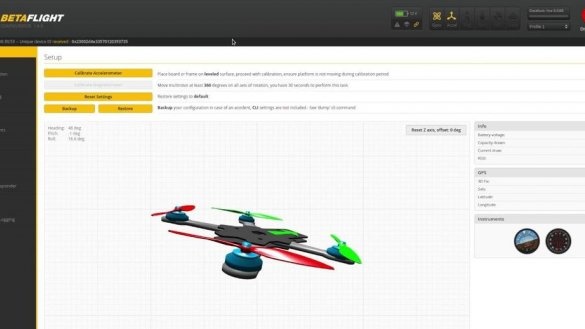

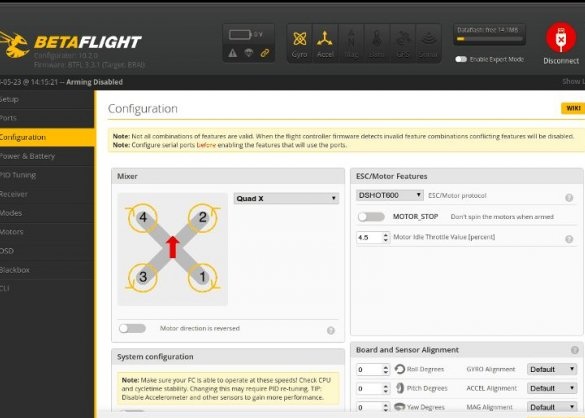

First you need to flash the controller with Betaflight firmware. Then calibrate the sensor. Connect the radio module and check its operation. Mount the motors on the frame according to the diagram of the X-frame with the correct direction of rotation. Solder the motor leads to the ESC terminals and fasten the ESC to the bracket. Attach the power distribution board and solder the ESC pads. Connect the Soler XT60 to the power cable, and then to the power distribution board. Fix the controller. Connect the wires from the ESC to the flight controller. Mount the receiver on the frame. Put on the top cover.