Thanks to this workshop, you will learn how to make an inexpensive sofa out of plywood. do it yourself. the author will also share the secret of making original welded metal legs.

Not one house can not do without a sofa, as this is the main element of comfort and relaxation. However, the cost of finished of furniture not always affordable for the average buyer. Therefore, the option to make a sofa with your own hands remains the only one available.

In order to make a sofa from plywood in home conditions you will need:

Materials:

- plywood with a thickness of 15-20 mm;

- glue for woodwork;

- putty on wood;

- polyurethane varnish on a water or oil basis;

- metal corners to strengthen the frame - 8 pcs;

- pillows instead of soft upholstery or dense fabric and furniture foam for their manufacture;

- a sheet of metal for the base of the legs;

- a solid metal rod of a round profile for the manufacture of legs;

- primer for metal;

- spray paint for metal;

- wood screws.

Instruments:

- manual circular or jigsaw;

- welding machine;

- a grinder with a cutting wheel for metal and a grinding nozzle for metal;

- screwdriver;

- electric drill;

- clamps and clamps;

- large ruler, square;

- putty knife for putty;

- a chisel;

- fine grain sanding paper or sanding sponge;

- paint roller and brush;

- sewing machine, iron, scissors, sewing centimeter;

- construction tape measure, marker.

Step one: making the side parts of the sofa

The author uses plywood up to 20 mm thick. To make a sofa, you will need first grade plywood without flaws. Each half consists of two blanks glued together.

Determine the overall dimensions of the side parts and cut 4 rectangular blanks.

Using a square and a large ruler, markup on one of the blanks so that you get a curly part.

Securely connect all four workpieces with clamps or clamps and cut with a hand circular or jigsaw. To ensure that the cut is perfectly even, use a guide rail instead of a ruler during cutting.

Glue the sidewall parts in pairs using special furniture glue. To do this, apply glue to the surface of the workpieces and evenly distribute over the entire plane, paying particular attention to the corners and edges.

Place the glued sides in the clamps until the glue completely dries.Drying time, see the packaging of the adhesive, it can vary significantly.

Step two: making the base of the sofa

The base of the sofa consists of flooring and a frame on its back. Cut the rectangle to fit the seat. Also prepare frame parts with a width of 50-60 mm.

Alternately glue the frame parts along the edge of the seat, placing the connection point in the clamps.

Step Three: Preliminary Preparation of Frame Elements

The author uses a chisel to cut off excess hardened glue along the edges of the workpieces. Try not to smear the liquid glue along the edges, since after it hardens, the putty does not fit well on the edges.

Walk along the edges with a spatula, applying a small amount of putty on wood. Fill all the cracks and leave the workpieces until the putty is completely dry. Then sand the edges manually using fine-grained sand paper or a special sponge.

Step Four: Build the Sofa

The author transfers the mounting marks from the sidewalls to the seat with the help of home-made patterns of plywood. In this way, locate the fasteners and drill holes for the screws.

Connect the sides and the sofa seat using metal corners. With the help of them, fix the back.

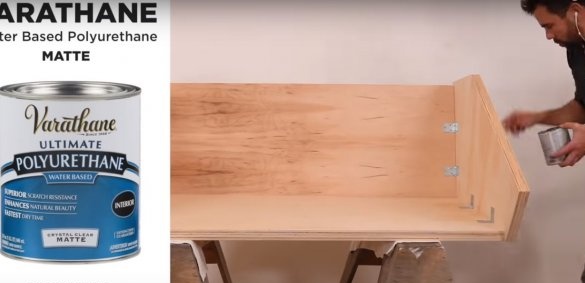

Step Five: Painting the Sofa

In order to protect plywood from mechanical damage, as well as from exposure to moisture and dust, the author uses a varnish - water polyurethane company Varathane. The varnish is applied using a roller or with a simple brush over the entire plane, including the edges and bottom of the sofa.

For the durability of the coating, apply the varnish in two or three layers with polishing of each layer, except for the last - the finish. Leave the varnish to solidify.

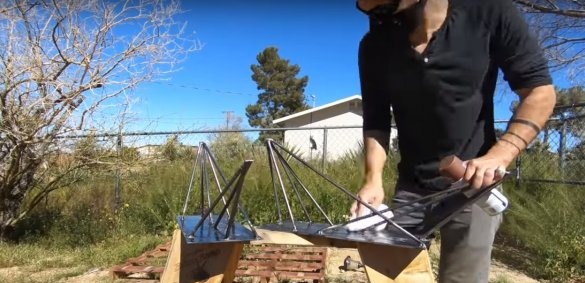

Step six: manufacturing and installation of welded legs

The author uses home-made metal legs made of a metal rod and metal plates. Parts are joined by welding.

You will need a solid metal rod with a round profile, which does not bend under the influence of a large weight - for example, under the weight of a person. You will also need a pair of rectangular metal plates - for the base of the legs.

But first, cut two parts from plywood and fix them on the back of the seat as a platform under the metal plates of the legs. Use glue and small screws.

Prepare the irregularly shaped piece for the legs as shown in the photo. Measure the approximate distance of the welded points to the corners and cut four rods for each leg - four main parts that determine the height of the legs.

Set the metal plate at right angles and fix the rods with small studs directly on the pattern - a pair on each side. Weld the rods, cut the excess and weld them together.

Weld another two or three rods on each side, clean the welding spots and the plate itself. Make several holes for the fasteners on each side.

Spray the primer. Paint the legs with white spray paint in two steps. In order to make the edges of the legs look more monolithic, the author dipped them in a thick white paint on metal.

Once the paint has dried, the legs can be fixed on the couch. Use small screws.

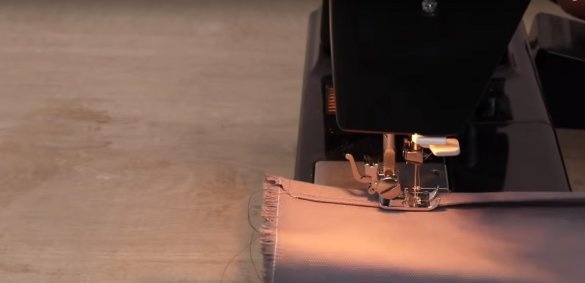

Seventh step: making pillows

For the manufacture of pillows you will need furniture foam at least 50 mm thick, thick fabric, iron and a sewing machine.

Cut the fabric to the size of the pillows with an allowance for double hem. Fold the fabric from the edge twice, ironing each bend. Sew the edge on the typewriter and steam it again with an iron. Place the foam inside, "close" the corners of the covers as shown in the photo and fix them with a thread with a needle manually. Sew linen hooks or sew a zipper at the edge.

It remains only to lay the pillows - and your sofa is ready!