In this article, Bob, the author of YouTube channel “I Like To Make Stuff”, is ready to give his readers a screen printing master class.

This technology allows you to apply the same pattern to several hundred products.

Materials

—

—

—

- Transparent film for printing on a printer

- Glass

- Masking tape.

Instruments, used by the author.

— .

Manufacturing process.

All that is needed is a screen, a rubber spatula and a special photosensitive adhesive. Usually this thing is sold in two bottles. The screen itself is usually quite expensive, I indicated in the materials where you can buy a special mesh made of polyester, from which you can make it yourself.

In a smaller bottle, sensitizer, add a little water and mix well. This will cause the polymer to lag behind the walls of the bottle.

Now it can be poured into a container with a glue emulsion, and mixed again very, very thoroughly, until the liquid inside gets a uniform green color.

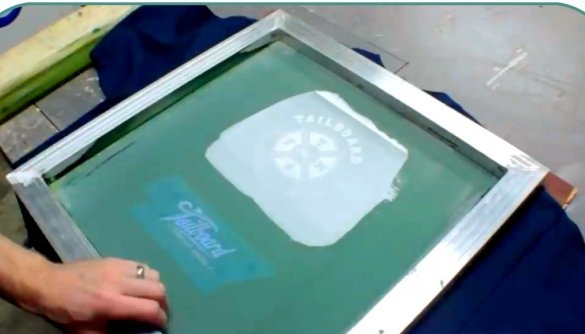

Then a small amount of this liquid is poured onto the screen, and the spatula is evenly distributed over the entire surface of the screen. Fluids need very little, since the rubber scraper is able to create a very thin uniform layer.

Now you need to flip the screen, and align the inner layer.

Make sure that you have covered the entire surface of the screen, and that the layer is uniform and even everywhere. Do not leave the screen in the light! Dry it with a hairdryer with the lights off.

When the screen dries, you have to act very quickly, because the substance is photosensitive, and easily freezes in the light.

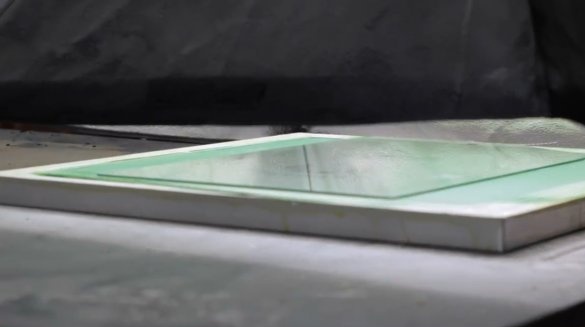

At this point, you should already have printed a ready-made stencil of a drawing, logo, emblem, on a transparent film. Lay it on the back of the screen. Put a piece of glass on top, slightly press down, place a very bright light above the screen, and leave everything for 30-45 minutes (read the instructions for the glue used).

The light caused the solidification of the emulsion, more precisely the part that was not covered by the stencil. Light green areas did not harden.

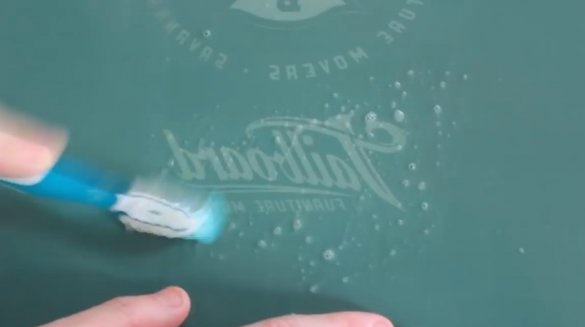

Now, using water and a soft brush, the author gently removes the paste from the screen.The principle of screen printing is that the dark, hardened areas of the photopolymer layer perform the function of an impermeable coating, while light areas allow ink to pass through onto the surface on which it is to be printed. Remove excess paste should be very gentle so as not to erase anything you need. True, mistakes on first attempts are inevitable.

If there are such areas that should not be imprinted on the product, unwanted gaps, then they can be covered with masking tape (but not with electrical tape or adhesive tape - these are more aggressive, and can remove the desired layer). Also, it can be used to close drawings if you have applied them to the screen at once.

Now it's time to put a T-shirt on the table and place the screen on top.

The author applies a thick layer of screen printing ink on fabric. At this point, it is important that someone or something properly fixes the screen. Now the author smears the paste with a confident movement using a scraper through the entire surface of the picture.

The screen must be lifted quickly, and without shifting to the side, otherwise the picture may be blurry.

Now the pattern should be fixed using heat. This can be achieved by throwing a T-shirt in the dryer for a few minutes.

The screen itself can also be reused if you clean it on both sides with a means for removing photocomposite mixtures. The product is quite caustic and should not be on the screen for more than a couple of minutes!

Then it should be thoroughly washed off a hose or shower. Sometimes, especially if using dark ink, traces of the pattern may remain on the screen. But they will not be a hindrance in the process - ink perfectly passes through them.

A little practice - and you will succeed! You will feel with what force to press on the scraper, which layer of paste to apply. Over time, many other subtleties of the process technology will open your intuition. Go for it!

Thanks to the author for the simple but interesting screen printing technology!

All good mood, good luck, and interesting ideas!

Author video can be found here.