Furniture from concrete, it has long and quietly migrated from the garden and terraces to our apartments and houses. But it is not only the practicality and durability of this material. Just concrete is in perfect harmony with modern interiors, creating competition for the familiar wood, plastic, MDF and metal.

The author of this workshop produced a coffee table in which he successfully combined concrete, metal and wood. He willingly shares the secret of how to inlaid concrete countertops with natural wood.

For his work, the author uses a CNC laser machine, but the general principle of work will also be useful to those who do not have such a machine.

In order to make a table with a concrete countertop inlaid with natural wood you will need:

Materials:

- ready-mixed concrete based on cement grade 5000 or cement, sand, water and plasticizer;

- Plexiglas of suitable thickness;

- wood veneer with a thickness of at least 5 mm for inlaying concrete countertops;

- Super glue;

- hot glue and silicone sealant for assembly and sealing of MDF molds;

- MDF or any suitable material for a mold with smooth walls;

- wood screws;

- quick-drying oil for wood processing, furniture wax if desired;

- matte varnish for concrete;

- metal blanks for legs;

- primer and white paint for metal;

- the remains of plywood and slats for the base under the legs.

Instruments:

- laser CNC machine;

- Miter saw;

- circular;

- grinder;

- screwdriver;

- glue gun;

- sanding paper with fine grain - 220-240;

- construction tape measure, square, marker.

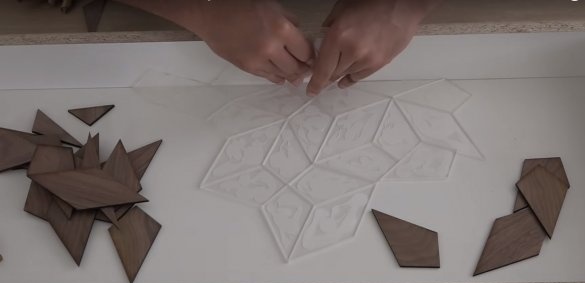

Step One: Making Inlay Elements

In order to cut diamonds from veneers for inlaying, the author uses a CNC laser machine. The advantage of such equipment is obvious, however, if you do not have a machine, use a jigsaw machine or just a hand jigsaw to cut wood from workpieces. Fit them to size using a grinder or manually using sanding paper.

You will also need identical plexiglass parts. Their author also cut using a laser machine.

Step two: the manufacture of formwork for concrete countertops

You will need a sealed formwork with a smooth surface for the manufacture of concrete worktops.

As a material for the mold for concrete, the author used the remains of MDF.Mark the formwork parts using a square. The height of the countertops will be no more than 10 cm.

Open the MDF sheet according to your drawings and assemble the mold with hot glue. The author also processes all external joints with hot glue. Coat the internal slots with silicone sealant.

Step three: preparatory work before filling the countertops

Put the wooden rhombuses in the finished form, arranging the pattern that you would like to get. Each rhombus alternately replace with parts from plexiglass. They must be fixed on the surface of the mold with glue. Make sure that there are no gaps between the rhombuses.

Prepare the base for the metal legs. As conceived by the author, it consists of a single piece of plywood. From above, a pair of limiter rails should be screwed onto the workpiece as shown in the photo.

Step Four: Making Concrete Countertops

Knead cement grout. The author uses a ready-mixed concrete mixture based on cement grade 5000. It is enough to add the right amount of water - and the solution is ready. Such a mixture can be replaced with ordinary cement mortar based on coarse sand with plasticizer and dye, which you can add if necessary. Also in the process of preparing the solution, you can use the so-called "white" cement. It gives the finished concrete products a very light, almost white hue.

Put the solution in the form without reporting a couple of centimeters to the top, tighten the corners. Lay plywood on top, slats up. Fill the form to the brim. To compact the solution, the author uses a vibration grinder.

Place the load on the plywood and leave the countertop for 2-3 days until completely solidified. Concrete should dry at a temperature not higher than room temperature and is constantly in a moist state.

Remove the formwork and slats from the plywood insert. Leave the countertop for a few more days until completely dry.

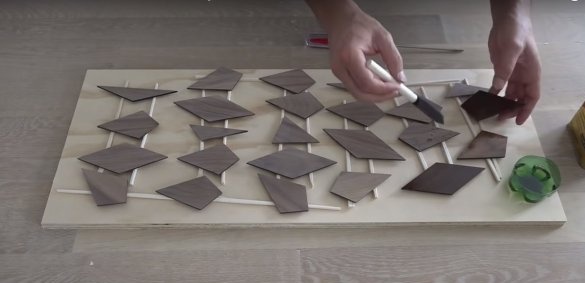

Step Five: Inlaying Concrete with Wood and Installing Feet

The metal legs should be painted. As the first layer you can use a primer, and after that - apply a couple of layers of white matte paint on the metal. Set the countertop on the legs and fix it with wood screws.

Carefully sand wooden diamonds manually, including the edges. Soak them with quick-drying oil on the front side. The oil will prevent the aging of wood and protect it from moisture.

Fix wooden diamonds on a concrete workpiece with super glue. Grind the inlaid zone with a grinder by rounding the corner. Oil the sanded areas.

If you wish, you can also use liquid furniture wax, which will further simplify the cleaning process. For the same purpose, the concrete countertop can be coated with a special matte varnish on concrete.

The coffee table with concrete worktop and metal legs is ready!