When scraps of old boards gather dust in the household, it's time to start manufacturing of furniture from a natural tree. Often, beginning craftsmen are afraid to use natural wood, especially if before that they had to deal with MDF, particleboard and plywood. However, working with wood is a pleasure. Get down to business - and see for yourself.

The author used a tree of the same species. But if you have several boards of different shades and different textures - feel free to experiment! Such furniture is quite popular and looks great. However, in the manufacture of the frame, try to use wood of approximately the same density. For example, maple, ash, oak or linden, alder, poplar. Pine in this case is more universal.

So, in order to make a table in the bedroom do it yourself you will need:

Materials:

- short cuts of a bar of rectangular section for the frame;

- 4 square bars for making legs;

- wide boards with a thickness of 25-35 mm for strapping the frame around the perimeter;

- boards 15-20 mm for the drawer frame;

- a sheet of plywood 6-10 mm to the bottom of the box;

- several massive boards for the manufacture of countertops;

- drawer handle;

- oil or special liquid wax for wood processing;

- furniture glue;

- nails;

- screws or self-tapping screw;

- accessories for a drawer.

Instruments:

- Miter saw;

- Grinder;

- electric drill;

- pneumatic nail gun;

- manual circular or jigsaw;

- a washcloth for applying oil and a lint-free cloth;

- square or ruler, construction tape measure, pencil.

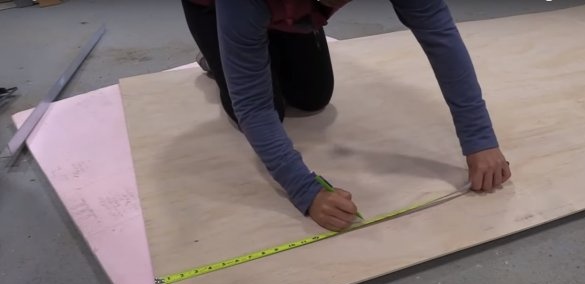

Step One: Preliminary Wood Preparation and Drawing

For the manufacture of furniture, trim boards are excellent. If the surface of the wood has acquired a gray tint or there are traces of the development of fungi, it should be planed and pre-sanded.

Mark out those parts whose dimensions are known. Grind all sections. To cut a tree, the author uses a miter saw. So she can be sure that even without careful marking, the parts fit snugly together.

Prepare a drawing of the table for your size.

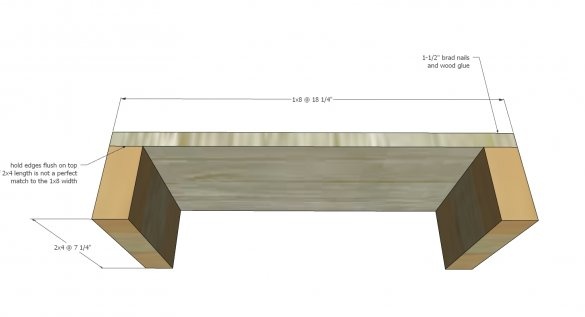

Step two: making the frame

To assemble the frame parts, the author uses a displaced joint joint. Short lengths of bar in the corners are the basis for fastening flashing parts flush.

The frame is assembled using furniture glue, screws and nails.Thanks to the glue, the design will last much longer, and the product will ultimately be stronger.

In order to prevent the wood from breaking when screwing in the screws, pre-drill holes.

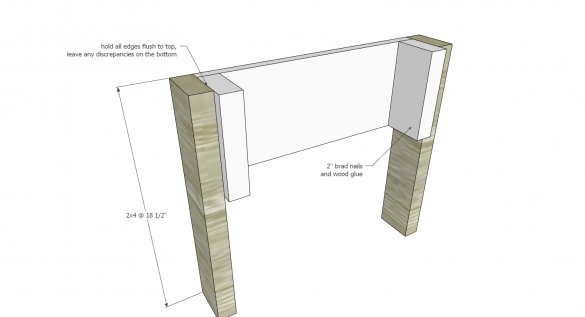

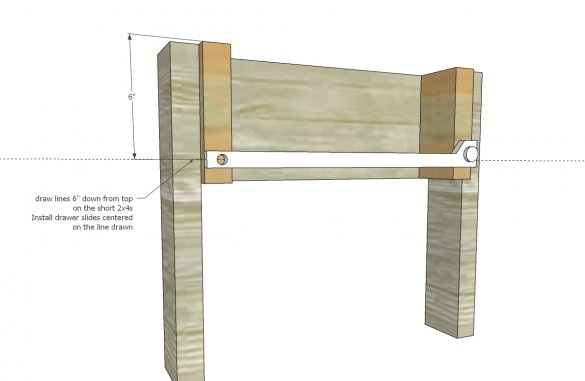

Assemble the two sidewalls as shown in the photo. Already at this stage, you can screw the guides for the box.

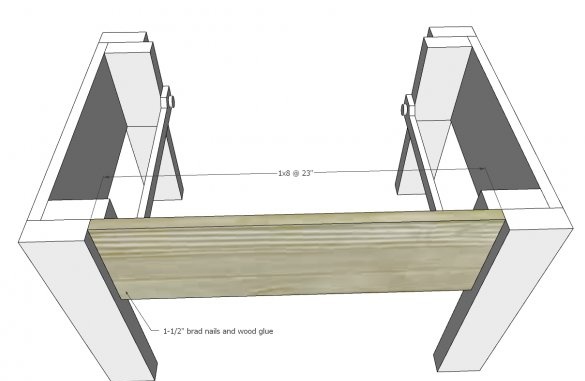

Connect the sidewalls with the rear jumper. The design is not too stable yet. At this stage, it should be so.

Step Three: Build and Install Box

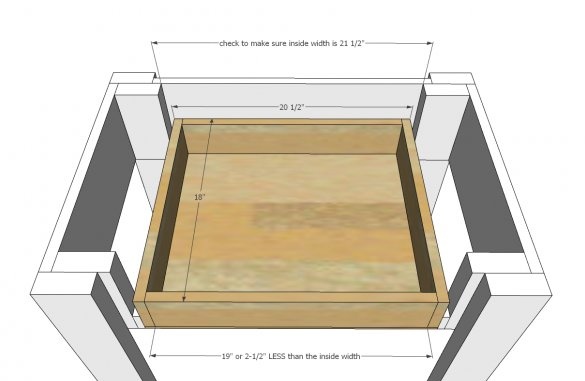

From boards of smaller thickness, assemble the frame of the box of 4 parts.

Using a hand circular or jigsaw, cut a piece of plywood into the shape of the bottom of the box. Secure it using glue and small nails.

Screw the sliding fittings with screws and put the box in place. If everything is assembled correctly, proceed to the next step.

Step Four: Final Assembly

The box inside the table will provide you with even geometry while you screw on the countertop, so leave it there.

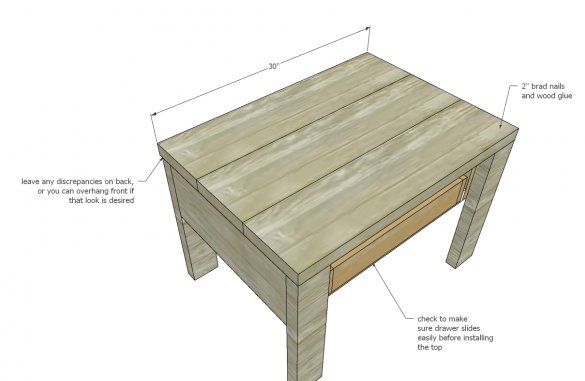

Boards for countertops must be pre-sanded on all sides.

For reliable fixation, be sure to use glue. Screws or self-tapping screws are optional, there are enough nails with the head.

Fix the front board of the countertop and check the smooth running of the drawer. Screw the rest of the board.

Step Five: final processing of the bedside table

If the quality of grinding does not suit you, it's time to go with the grinder where necessary.

Remove dust from the surface of the wood and start painting.

The author used Varathane quick-drying oil. In addition to oil, it contains solvents and waxes, thanks to which the wood acquires reliable protection against moisture, as well as a special silky sheen. Such coatings completely dry within 12-24 hours. If a surface of perfect quality is required, the wood is again polished with grain of at least 220-240 and liquid or semi-liquid furniture wax is used to fix the result. Thanks to this technique, the surface of the tree acquires bone density.

So, apply the oil with a kitchen washcloth, thick foam rubber or just a cloth. Be sure to remove any residues. Let the oil dry at room temperature according to the instructions.

It remains only to screw the handle of the drawer, and the bedside table in the bedroom is ready!

a wadded table in the bedroom is ready!