When repairing equipment, a problem often arises when removing bearings, gears and disassembling other components. Hammering on an axis or gear cannot be done, this will lead to a curvature or damage to the thread, for such tasks a puller is needed. One author showed how to make a simple and powerful puller, but homemade can be done if there is a lathe. However, you can do without a lathe if you know how to make accurate calculations. One way or another, if you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- thick sheet steel;

- threaded rod and nuts (preferably with a "power" thread);

- round timber;

- paint;

- a suitable handle (possible from the valve).

Tool List:

- lathe;

- welding;

- grinder;

- drilling machine;

- Miter saw.

Homemade manufacturing process:

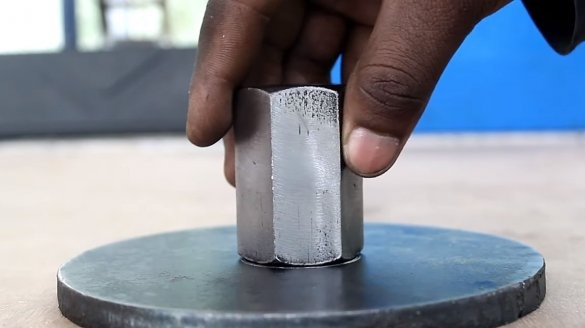

Step one. The foundation

First of all, we will make the basis for the puller, for this the author found a circle of thick sheet steel. We grind the circle with a grinder in order to remove rust and burrs, and then, clearly in the center, we need to drill a hole for the threaded shaft. The author quickly and accurately drilled a hole using a lathe. You can cope with the help of a drilling machine, but first you need to find the exact center of the circle.

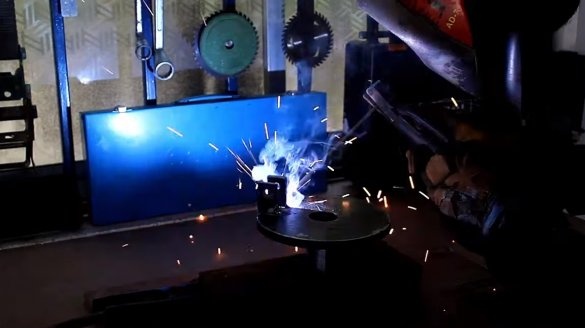

Further, the author made a nut by welding two nuts together. The greater the length of the nut, the higher loads the thread will be able to withstand. At the end, we weld the nut opposite the hole clearly perpendicular to the base so that the shaft does not go sideways.

Step Two Ears and paws

We weld steel sheet ears to the base, and we will pivotally attach the paws to these brackets. As for the paws, their author made of round timber, and steel plates were welded to the paws as hooks. In the paws, drill holes for mounting screws.

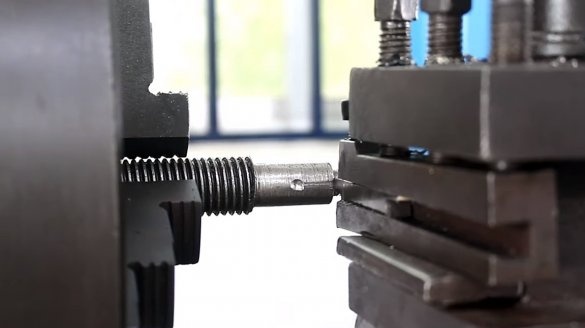

Step Three Threaded shaft

The author finalized the threaded shaft on a lathe; you need to sharpen its end so that the shaft is centered at the desired point when pressing out.On the reverse side of the shaft, the author removed the thread and made a groove, the handle from the valve will be attached here. Also, for fastening the handle, the author machined the end of the shaft to the desired diameter and cut the thread under the nut.

Step Four Assembly and testing

We paint all the details, and the puller can be assembled. Of course, the homemade product weighs a lot, but the puller in practice turned out to be quite powerful. To facilitate the design, it would be nice to use a steel rod as a handle, and it can be removable. Paws can also be made of pipes with a thick wall, such paws should quite cope with the loads.

The homemade product is ready for this, the author easily removes the gear from the shaft. I hope you enjoyed your homemade work and found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!