The idea is simple, but quite effective. 13 million views on YouTube. And it is not homemade for the sake of homemade work, but a really working tool.

So, for its manufacture we need the following

Tools and materials:

-Bearing large size (the master 25 cm diameter);

-Metal plate -10 mm;

-USHM;

-Welding machine;

- Steel circle - 30 mm;

-Vise;

Step One: Plate

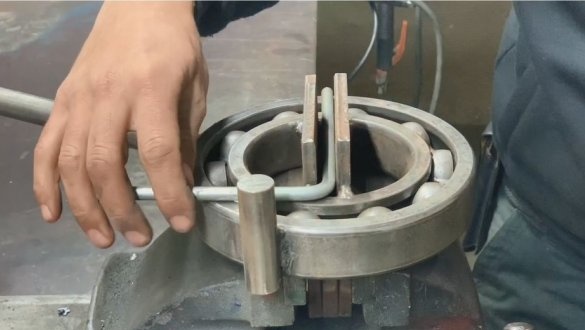

It is necessary to cut off three plates, two plates (extreme) in height should protrude beyond the bearing on both sides, a third (middle) protrudes from one side. The length of the plate should fit inside the cage from edge to edge. Then the plates are welded and welded to the inner race of the bearing.

Step two: handle and stop

The steel circle cuts into two parts, one long will be the handle, the second short will be an emphasis. A handle is welded to the outer race of the bearing. Across the outer ring welds the stop. One side of the stop should protrude above the bearing.

Here's what you get, this is the upper working part of the tool.

Step Three: Use

To use the bending tool, you need to clamp three plates welded together in a vice. Between the two upper plates the workpiece is hindered. By the handle, the outer bearing race is rotated and the workpiece is bent with an emphasis.

To understand the process, you can watch the video, especially since there are several ways to improve it in the comments fixtures.