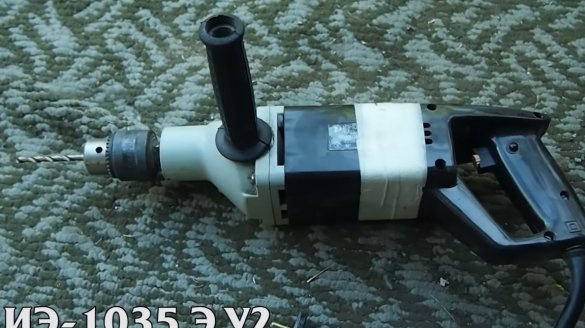

Greetings to all fans of creating do it yourselfToday we will look at how to make a simple and reliable drilling machine. The author installed a rather powerful drill on his machine, as a result, with this machine you can even drill holes of a rather large diameter. As a basis, the author used a piece of a profile pipe and sheet steel. The drive is carried out due to a bicycle candle and a carriage; the machine is very convenient in operation. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- a piece of a rectangular profile pipe for a rack;

- a piece of thick sheet steel for the base;

- bicycle chain and rear carriage;

- profile pipes for handles and a movable block;

- Sheet steel;

- a sheet of rubber for the base;

- paint.

Tool List:

- grinder;

- ;

- roulette;

- marker.

Manufacturing process homemade:

Step one. The foundation

We take a thick sheet of steel and weld to it clearly at right angles a piece of a square or rectangular shaped pipe. We carefully measure everything with charcoal from all sides, if the angle is not right, there will be no sense from such a drilling machine.

We weld a bicycle chain to the rack, it will serve as a hook for the sprocket, which is located in the movable block.

Step Two Movable unit

We make a movable block, a piece of a profile pipe that can be bent from sheet steel will slide along the rack. It is important that all backlash in the machine is minimal, otherwise it will affect the accuracy of drilling.

We make a movable block, as a basis we use profile pipes, or pieces of a corner from sheet steel. In the block there will be a carriage with a bicycle sprocket. Everything should be assembled so that the star clings to the chain. As a result, turning the shaft, we will raise the block or lower.

Step Three Drill mount

The drill is attached to the movable block very simply - with the help of a clamp.The author made such a collar from a piece of a round pipe of suitable diameter. As a clamp, we weld two nuts, in one nut you need to drill a thread. The collar is reliably pulled together with a bolt.

Step Four Pen and painting[b] [/ b]

We weld a handle from profile pipes, weld it to the axis of the carriage. That's all, now all that remains is to paint it well. Before assembly, we grind the guide well with sandpaper and grease with grease.

The homemade product is ready, when the handle is idle, the carriage moves a little jerkily, since there are no backlashes. But the author assures that under load, during the drilling process, there are no jerks. As an experiment, the author drilled a bar with a large diameter drill.

The holes were drilled quite accurately, and the diameter of the holes did not break, which indicates the absence of backlash in the structure.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!