In this article, Steve, the author of the YouTube channel "Steve Ramsey - Woodworking for Mere Mortals", will give an overview of the different types of grinding machines, focus on the four most necessary and practical. And also he will talk about ways to use them most effectively.

Materials

- Boards.

Instruments, used by the author.

- Drum, orbital and belt grinding machines

—

- Belt and vibration grinding machines.

Manufacturing process.

Most beginner joiners prefer to work with a simple orbital sander. It can rightfully be considered one of the main woodworking tools. But on it, as they say, the light did not converge in a wedge. There are other grinding machines that can make your work in the workshop more efficient and joyful. Do not neglect them!

So, the author begins his review with just such an aggregate: a belt and disk grinder, two in one! Although you can meet them separately.

As the author himself admits, in the beginning, he increasingly worked with a disk machine, not counting the tape as something useful. But over time, the master began to find him more and more areas of application, in particular for processing small elements, where you need to penetrate into all kinds of bends and tricky corners, into grooves and slots - here the belt grinder is irreplaceable and masterfully cope with its task.

They can grind even such artistic things. This anatomical hand is made entirely of wood.

You can also make small items.

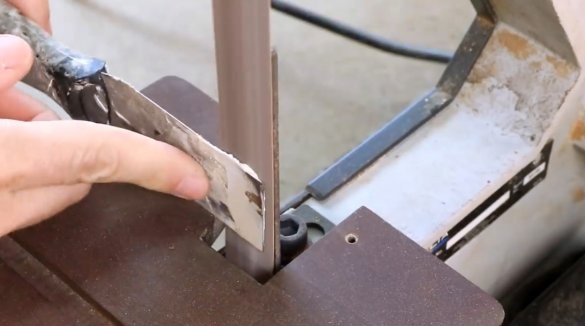

Its second purpose is sharpening tools: chisels, knives, blades. And also on the tape machine it is possible to clean the tool remarkably of dried materials.

Disk grinding machine is mainly designed to handle external fillets, corners and bends. In this kit, the diameter of the disc is 8 inches, although you can also find smaller discs, for example, 5 inches.

The advantage of a disk grinder over an orbital grinder is that the former has a table with which it is easier to maintain a 90-degree angle when turning parts, and, therefore, a smoother surface can be obtained.

In addition, the table of the disc grinder can be tilted in such a way that it is possible to grind the beveled surfaces on the machine with exact observance of the necessary tilt.

The disk machine is especially effective where you need to grind something exactly to a given line. The only thing the author does not particularly like about this is that the machine uses self-adhesive emery wheels. Tearing them off is sheer torment. Therefore, the master simply buys 120 grit sandpaper and uses it until it is wiped off.

The next device is a drum grinding machine. Use it to handle internal bends well. This device is sold with nozzles of various diameters. And sandpaper is attached in rolls.

The washer polishes the surface due to rotation, but in addition it oscillates up and down, thus leveling out possible scratches.

First, the diameter of the drum is selected, it should be optimally suited for your bend. The washer is fixed on top with a nut. Such a nozzle is capable of processing both large holes and cutouts, and very small ones, even climbing into hard-to-reach areas.

The next type is a vibratory sander for small jobs. Unlike the orbital sander, this one can penetrate the most difficult places, thanks to the pointed end in the shape of the sole of the iron. Another advantage of this machine is its low weight and, due to this, higher maneuverability.

In this regard, the orbital sander is much harder to keep in those positions where the force of gravity is turned on.

And finally, the belt sander is the most aggressive model grinding machines. Its main purpose is the rapid removal of a large amount of material. True, to work with it will require a certain amount of skill, otherwise, not taking into account its specific functional subtleties, you can easily ruin the workpiece or the finished product. It is important not to keep the unit for a long time in one place, otherwise it may bite deep into the tree. Move it evenly - it should be in constant motion.

It can also be turned upside down, clamped with clamps and work on it, as on a stationary belt grinding machine. This gives more control over the process, because you are moving the part, not the machine itself.

Another option is a stationary belt sander. Its belt is approximately 4 inches wide. It is quite bulky, but many masters like it.

Ideally, the workshop should have several types of grinding equipment. Watch, study, choose!

I thank the author for a simple and accessible overview of various machines and how to use them!

All good mood, good luck, and interesting ideas!

Author video can be found here.