In this article, David, the author of YouTube channel “Make Something”, is planning another optimization of the workspace in his workshop and wants to share the results with his readers.

This time he intends to get rid of uncomfortable stops on the table near the miter saw. Even before this emphasis was made by him together with the workplace. But over time, the emphasis somewhat led, and this affected the quality of work. And the author comes up with a wonderful idea: a full-time emphasis is not needed, a T-shaped profile and a restrictive system are required.

Materials

- Hazelnut plywood

- Wooden beam

- T - shaped profile

- Impregnation for wood, varnish

- PVA glue

- The wing screw.

Instruments, used by the author.

- Drilling machine

- A circular saw

- Miter saw

— .

Manufacturing process.

So, the first thing the author dismantles the guide, and removes the countertop.

On a circular saw, he cuts a little its new blank from sheet plywood in size.

Guide Width направля inch.

The author is armed with a manual mill with a flat mill of exactly the same size - ¾ inch.

He will make a groove in the countertop in two steps. In one pass, it will remove half the thickness of the groove, in the second - all the remaining material.

In the second pass, it is necessary that the cutter protrudes slightly above the profile, so that the path itself lies slightly below the surface of the countertop.

Here, on the front of the countertop lies an edge. It is easily glued with an iron.

The countertop returns to its original place and is opened with three layers of varnish. This is plywood from hazel wood.

It's time to insert the T-rail.

On the previous version of the table, the countertop did not protrude so much beyond its edges. Here, a rather wide plumb line turned out so that the countertop almost rested against the trimming machine. There are some limitations. In particular, when the saw was rotated 45 degrees, its far edge began to rest against the countertop.

David just makes a small cutout and the problem is solved.Now the saw unfolds a full 50 degrees.

Next, the author proceeds to the manufacture of restrictive blocks. Hazel wood is used for them.

A deep groove is made in the middle of each block.

Inside the slot, these guide blocks are inserted, which should "sit" in the groove of the T-shaped track, like wheels in a track. Such a device of restrictive blocks will allow them to be stably at right angles to the saw blade. These small planks are glued into the grooves.

Further, David drills a hole for clamping screws in each block.

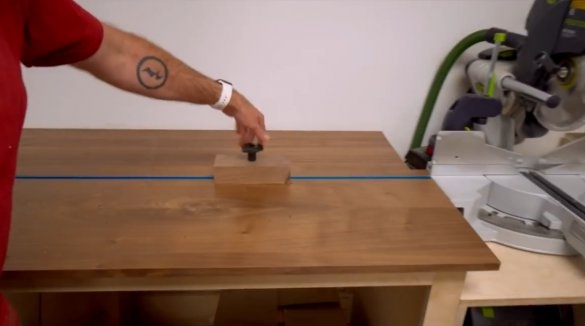

So, the head of the bolt is inserted into the track, a wooden block is mounted on it, which is pressed to the track with the help of such a wing handle.

In conclusion, the author on the sides of the restrictive blocks removes small chamfers at an angle of 45 degrees.

The surfaces are sanded with sandpaper, and the blocks are covered with several layers of varnish.

Take a look at how this works. Everything is fixed conveniently and reliably!

Since there is no emphasis, a lot of space is freed up. So, here, along the wall at the edge of the table, the master intends to make several cabinets with drawers where all kinds of tools and hardware will be stored.

I thank the author for the simple but useful improvement of the workbench for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.