Good health to all, dear the inhabitants of our site.

Today I have a story about a Chinese-made mini-vacuum cleaner that I had to bring to life and get to work.

1. Background.

I bought this device for its intended use, according to its intended use.

Specifically, my mini-vacuum cleaner was marked as follows.

The first test a little disappointed me. He can collect what is on top (on the table, on the keyboard), but he cannot get water under the keys to get trash, even using an additional nozzle with a brush. Used a couple of times and forgot about it.

When you work on model ship you use different material. And wood, and plywood, and pieces of plexiglass, and metal shavings also happen. But, here it is somewhat problematic to clean up waste. Fine fractions always remain that are difficult to remove. I thought it would be nice to have a small vacuum cleaner on hand for this purpose. And then I remembered about this forgotten device. I decided to apply it.

2. First use.

To solve the problem with its power, I bought a 220 - 5V power adapter for its power

And at the first opportunity I applied it. Here, as they say, "heap in full." Much of what was on the table hit my face. Since the fan outlet grille for the air outlet was directly in front of the face.

The rest that remained in the garbage collection container, after turning off the vacuum cleaner, immediately spilled out onto the table. When I opened the receiving chamber, I saw that a piece of non-woven fabric acting as a filter, slightly moved to the side. This little hole was enough to powder my face. Removed the filter, decided to clean it, it turned out to be problematic. The reasons I think are clear and so, without a description.

It became clear that in order to use it (vacuum cleaner), it is necessary to modernize the device somewhat.

3. Modernization.

And so, the first (production) application revealed the following disadvantages:

- the collected garbage is poured out of the container to collect it,

- the filter is very quickly clogged and poorly cleaned,

- air exhaust from the impeller with leaked dust enters the face.

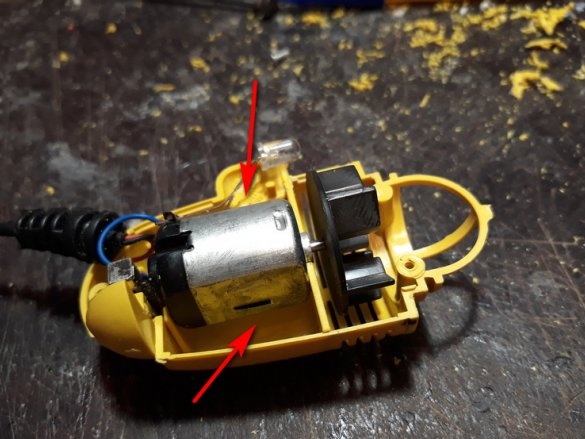

To begin with, I decided to make sure that our plan is possible. Having disassembled the compartment with the engine of the vacuum cleaner, I was convinced that this is possible - you can skip the air flow around the engine, as there is a place (pockets). And most importantly, the engine manifold is closed.

The first thing I did was to mark the holes for air to escape from under the impeller of the engine. Intentionally placing them in the lower part of both halves of the casing.

After drilling, the holes were cleaned and processed.

Then, on the middle bulkhead of the engine compartment, I made a marking for the passage of air directly from the impeller.

Then he sawed it out according to the marking, using a drill and a mill.

Now the turn came to the holes in the front of the engine compartment.

Which brought me so much "joy." They were sealed with stripes from a sheet of office paper. Then they were impregnated with glue "Second moment".

Next, smoothly go to the hemisphere of the air filter.

Initially, I thought to completely remove it. But then, I decided to leave. Because, thereby we will reduce the area of air intake, and this is not very good.

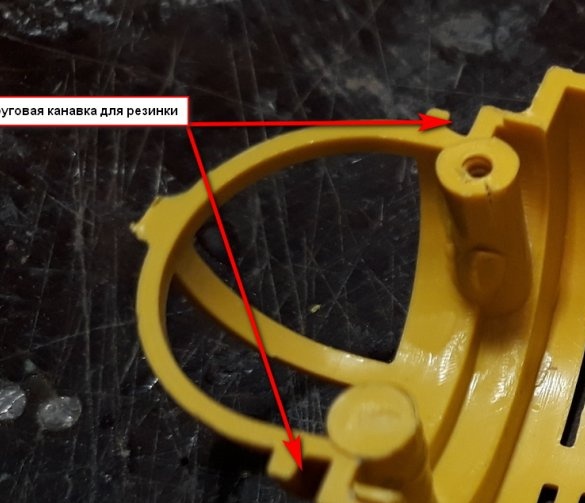

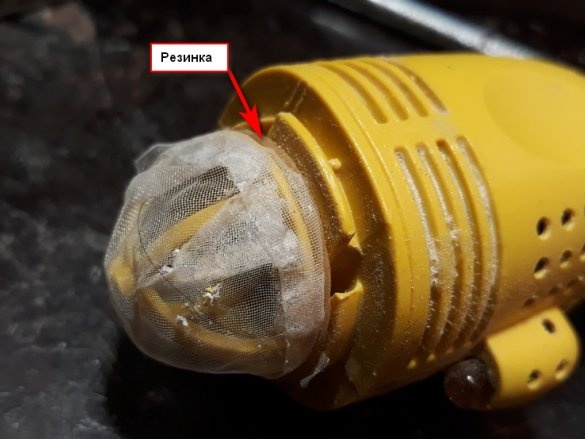

The filter from a nonwoven cloth decided to replace with a fine mesh, from tea bags. Having formed from it, with the help of glue, a hemisphere.

Mount left too - gum. The use of the tea net is due to the fact that it is very small and large waste does not stick to it, it falls into the garbage container. Dust, if it passes, then with a stream of air it will be discharged down the vacuum cleaner without getting into the face.

We pass to the last point of modernization. This is a waste container. Its not an intricate device and allowed, after turning off the vacuum cleaner to fall back onto the table. There was simply no place for waste.

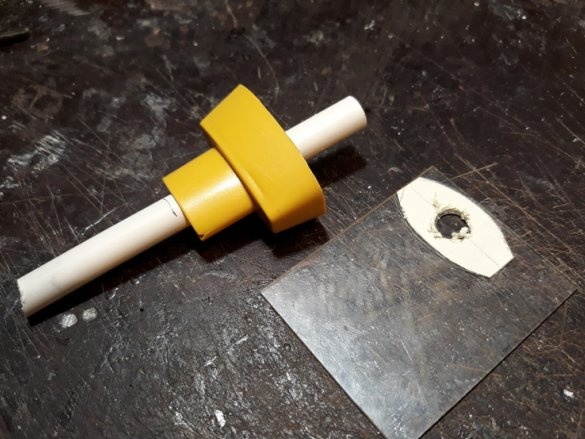

I decided to fix this matter, the more it is done very simply. I inserted a plastic tube into the suction tip of the vacuum cleaner with a suitable one, though almost half the size of the initial one.

What allowed to slightly increase the suction speed at the inlet of the tube.

The tube was fixed through a plastic partition with a housing.

Put on the tip.

The trick is that inside the tube is significantly raised from the point of entry into the housing.

Thus, waste falling into the container body, by an overwhelming majority, falls past the inlet. Thus, when you turn off the vacuum cleaner, it does not fall out onto the table.

4. Test in business.

While I was upgrading the vacuum cleaner, I had to repeatedly remove the waste with a brush. But, at the end of the work, I specifically left a little for the test.

And so, the time has come.

He turned on the vacuum cleaner and brought it to a bunch of waste, moreover, of various sizes. And he successfully coped. Everything turned out to be in a garbage collection container and when turned off, nothing fell out of it.

The filter mesh was not clogged with debris. When you disconnect the container, the collected one is easily removed from it, it just spills out.

But, the photo is the photo. And for clarity, I shot a video. You can see this the link

In conclusion, I want to say that of course you can, even probably need to, refine this beautiful device. On the inlet pipe - put a brush, for example. I still don’t really like the impeller of the vacuum cleaner itself, it’s straight. Without tilting the blades. From this, the air flow is not directed, but chaotic. Hence the suction force is completely different.

I think that this is all ahead. Most importantly, everything works and I have a good helper.

That's it.

See, criticize, advise, ask.

Regards, Starp.